A gan-based LED epitaxial wafer, epitaxial growth method and LED chip

A LED epitaxial wafer, epitaxial growth technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of LED luminous efficiency decline, difficult growth of P-type GaN layer, etc., to increase the concentration of activated Mg, improve crystal quality, improve Effect of Ga atomic mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

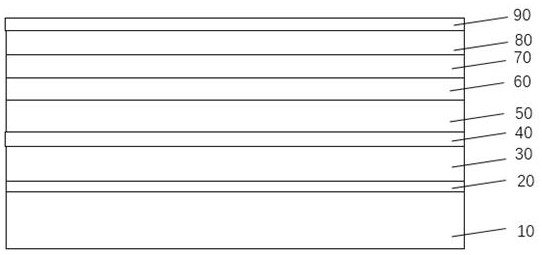

[0031] see figure 1 and figure 2 , shows the GaN-based LED epitaxial wafer in the first embodiment of the present invention, including a substrate 10, a buffer layer 20 stacked in sequence on the substrate 10, an undoped GaN layer 30, an N-type GaN layer 40, a multi-quantum Well layer 50 , low temperature P-type GaN layer 60 , electron blocking layer 70 , P-type GaN layer 80 and P-type contact layer 90 .

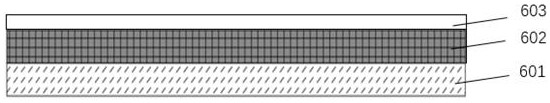

[0032] In this embodiment, the low-temperature P-type GaN layer 60 includes a first low-temperature P-type GaN sub-layer 601, a second low-temperature P-type GaN sub-layer 602, and a third low-temperature P-type GaN sub-layer 603, which are stacked in sequence. Both the low-temperature P-type GaN sublayer 601 and the second low-temperature P-type GaN sub-layer 602 are AlInGaN layers that are heavily doped with Mg, and the third low-temperature P-type GaN sub-layer 603 is a Mg-undoped GaN layer. MOCVD (Metal-organic Chemical Vapor Deposition, referred to as: metal organic ...

Embodiment 2

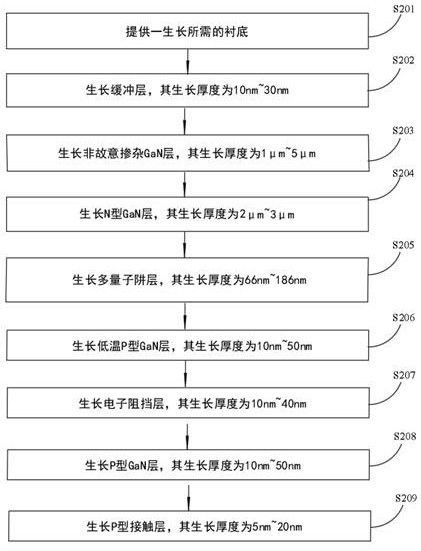

[0037] see image 3 , shows an epitaxial growth method of an LED epitaxial wafer proposed in the second embodiment of the present invention, which is used to prepare the GaN-based LED epitaxial wafer in the above-mentioned first embodiment. The method specifically includes steps S201 to S209, wherein:

[0038] Step S201, providing a substrate required for growth.

[0039] In this embodiment, the substrate is a sapphire substrate, which is an example but not a limitation. In some preferred embodiments of this embodiment, the substrate may also be a silicon substrate, a silicon carbide substrate, a gallium nitride substrate, an oxide Zinc substrates, etc. Among them, the sapphire substrate is selected because of its mature preparation process, large output, low cost, and excellent chemical stability and thermal stability.

[0040] In step S202, a buffer layer is grown, and the growth thickness thereof is 10 nm˜30 nm.

[0041] Specifically, the buffer layer is an AlN layer, whi...

Embodiment 3

[0066] The third embodiment of the present invention provides an LED chip, including the LED epitaxial wafer in the first embodiment. The LED epitaxial wafer can be epitaxially grown by the epitaxial growth method of the LED epitaxial wafer in the second embodiment.

[0067] In this embodiment, the thickness of the low-temperature P-type GaN layer in the LED chip is 20 nm, and the atmosphere is NH when growing the low-temperature P-type GaN layer. 3 / H 2 / N 2 The ratio is 1:1.3:2.3, wherein the thickness of the second low-temperature P-type GaN sub-layer is twice the thickness of the first low-temperature P-type GaN sub-layer, and the thickness of the first low-temperature P-type GaN sub-layer is the same as the thickness of the third low-temperature P-type GaN sub-layer. The layer thicknesses are the same, in addition, the first low temperature P-type GaN sublayer is Al 0.02 In 0.05 Ga 0.93 N layer, second low temperature P-type GaN sublayer is Al 0.007 In 0.05 Ga 0.94...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com