Intelligent pressure relief equipment for box-type substation

A box-type substation, intelligent technology, applied in distribution substation, substation/switchgear cooling/ventilation, substation/switch layout details, etc., can solve the problems of interval equipment damage, box bursting, high voltage, etc., and achieve good waterproof Effects of dust prevention and increased pressure relief capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

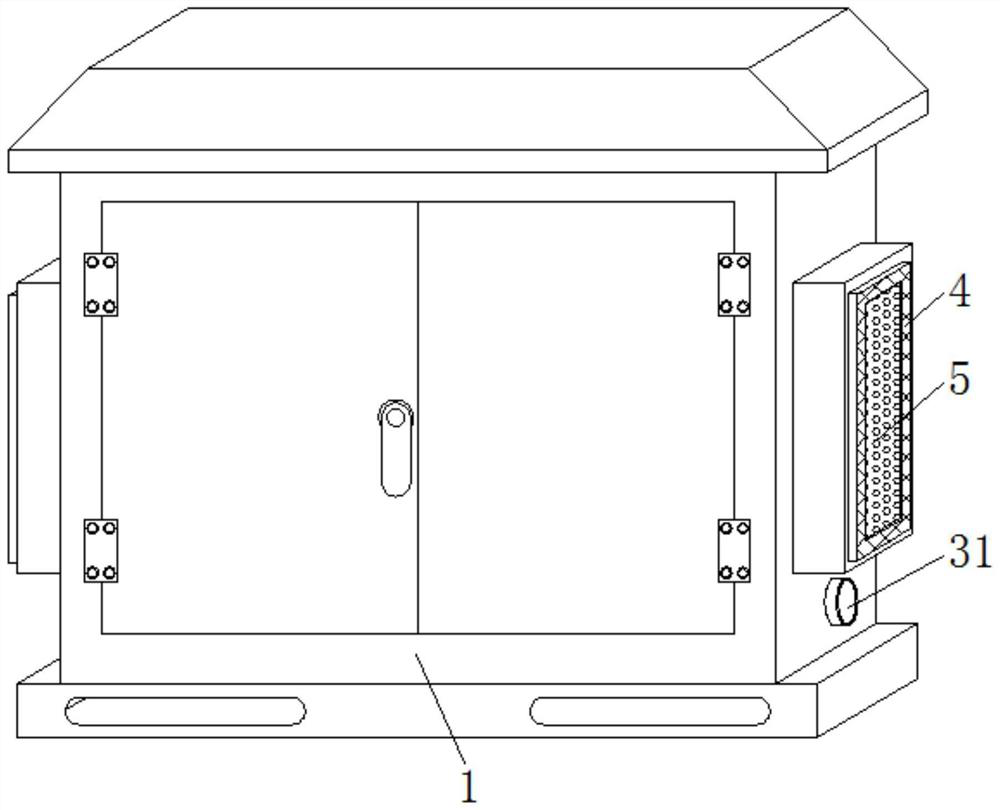

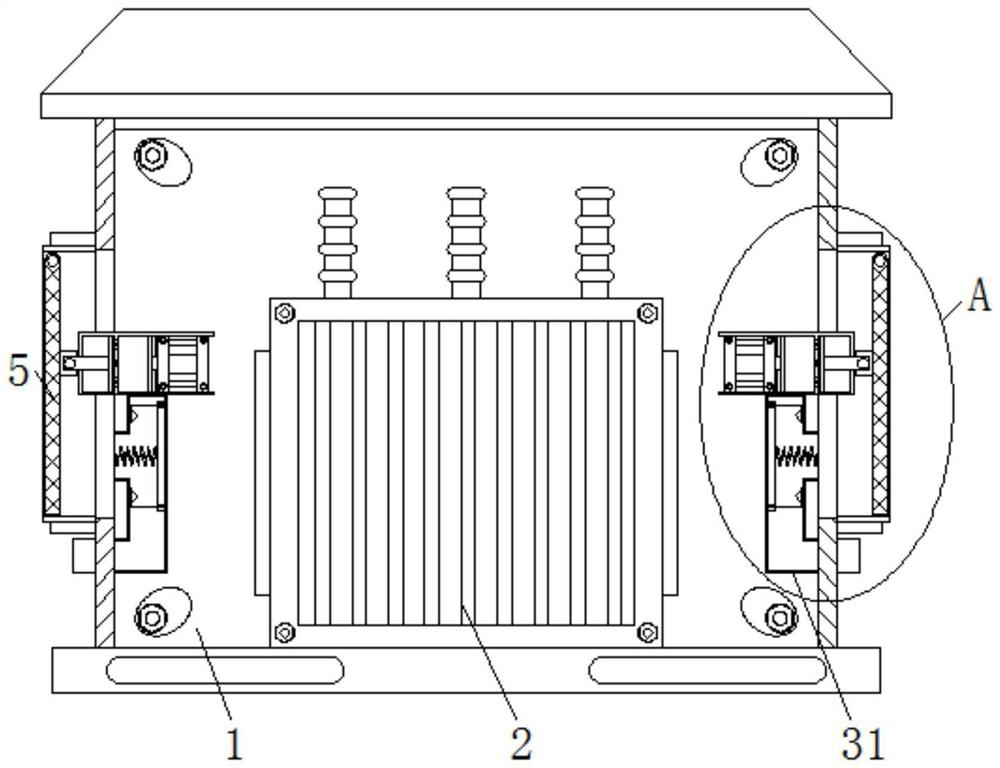

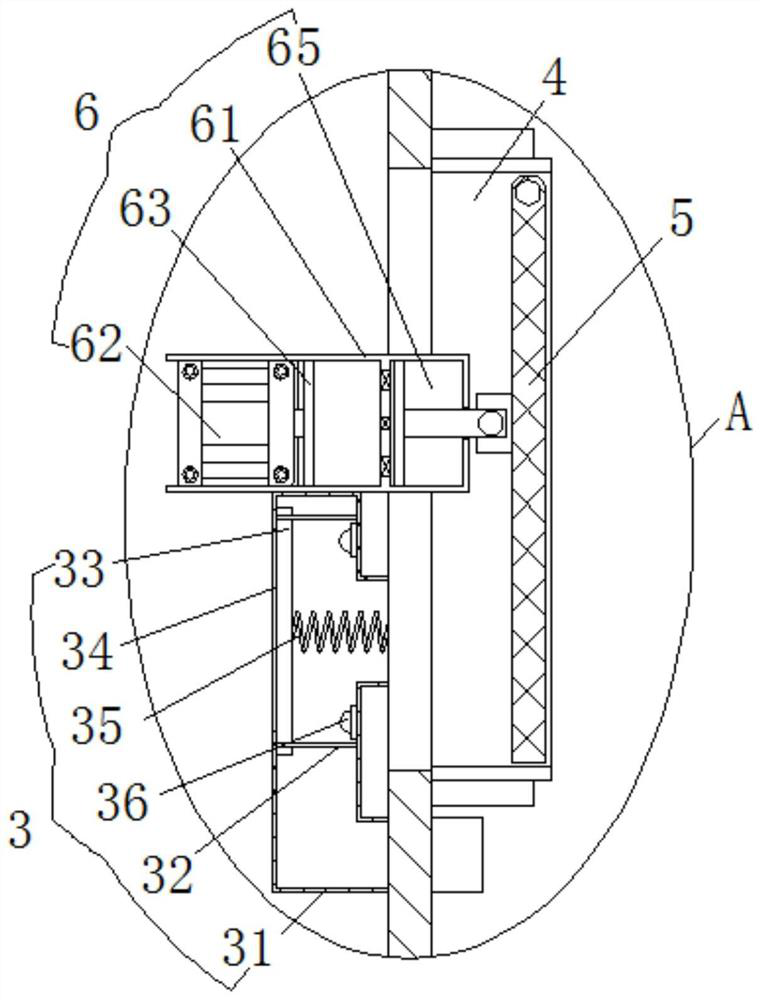

[0026] see Figure 1-4 , an intelligent pressure relief device for box-type substations, including a conventional pressure relief assembly 3, a pressure relief pipe 31 is arranged inside the conventional pressure relief assembly 3, the pressure relief pipe 31 is an L-shaped structure, and the bottom of the right side is in the Below the heat dissipation window 4, the top inside the pressure relief pipe 31 is welded with a fixed rod 32, and the outer wall of the fixed rod 32 is slidably connected with a gray plate 33, and the top of the left side of the pressure relief pipe 31 is provided with a pressure relief port 34, and the gray plate 33 is blocked on the right side of the pressure relief port 34, and the area of the gray retaining plate 33 is greater than the area inside the pressure relief port 34, and the right side of the gray retaining plate 33 is fixedly connected with a supporting spring 35, and the supporting spring 35 is far away from the gray retaining plate 33. ...

Embodiment 2

[0030] see Figure 2-5 , an intelligent pressure relief device for box-type substations, including a high-pressure pressure relief assembly 6, a fixed groove 61 is arranged inside the high-pressure pressure relief assembly 6, and a telescopic cylinder 62 is fixedly connected to the left side of the fixed groove 61, and the telescopic cylinder The right side of 62 is fixedly connected with the first sealing plate 63, the outer wall on the right side of the first sealing plate 63 is slidingly connected with the first hydraulic groove 64, the inside of the fixed groove 61 right side is provided with the second hydraulic groove 65, the second hydraulic groove The inside of 65 is slidably connected with a second sealing plate 66, the right side of the second sealing plate 66 is welded with a push rod 67, the right side of the push rod 67 is riveted to the left side of the cooling net 5, and the right side of the first hydraulic tank 64 is set There is a one-way oil outlet valve 68,...

Embodiment 3

[0035] see Figure 1-5, an intelligent pressure relief device for box-type substations, including a conventional pressure relief assembly 3, a pressure relief pipe 31 is arranged inside the conventional pressure relief assembly 3, the pressure relief pipe 31 is an L-shaped structure, and the bottom of the right side is in the Below the heat dissipation window 4, the top inside the pressure relief pipe 31 is welded with a fixed rod 32, and the outer wall of the fixed rod 32 is slidably connected with a gray plate 33, and the top of the left side of the pressure relief pipe 31 is provided with a pressure relief port 34, and the gray plate 33 is blocked on the right side of the pressure relief port 34, and the area of the gray retaining plate 33 is greater than the area inside the pressure relief port 34, and the right side of the gray retaining plate 33 is fixedly connected with a supporting spring 35, and the supporting spring 35 is far away from the gray retaining plate 33. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com