Self-heating type coal mine drying flexible screen

A flexible and screen technology, which is applied in the field of self-heating coal mine drying flexible screen, can solve the problems of polluting smoke and gas, inconvenient transformation, unfriendly environment, etc., to achieve cost saving, increase production efficiency, and direct drying and dehydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

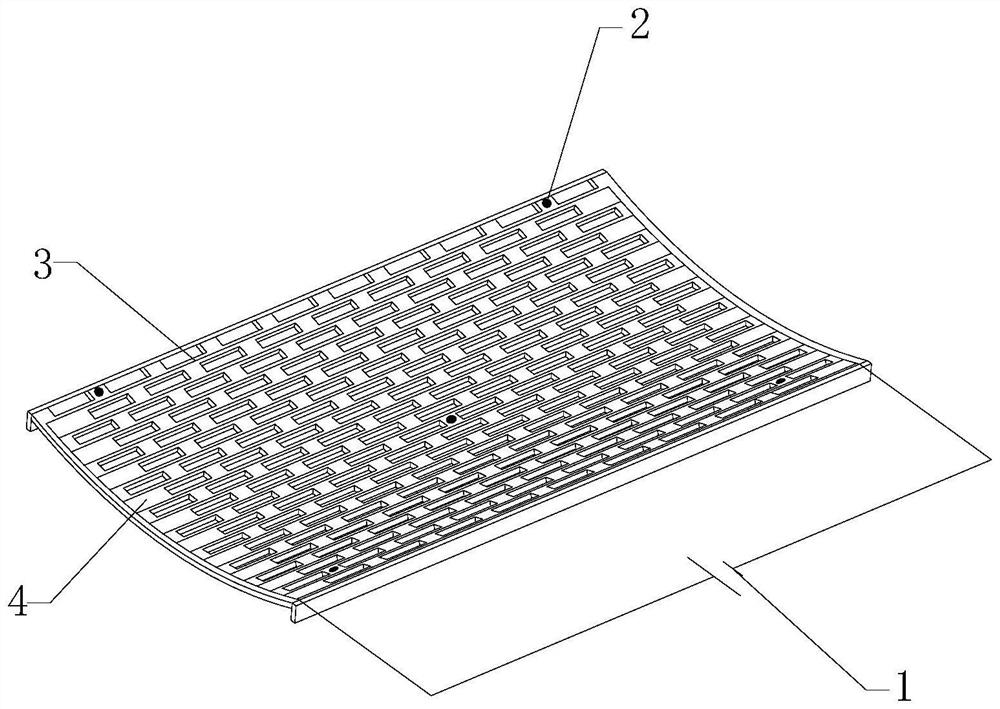

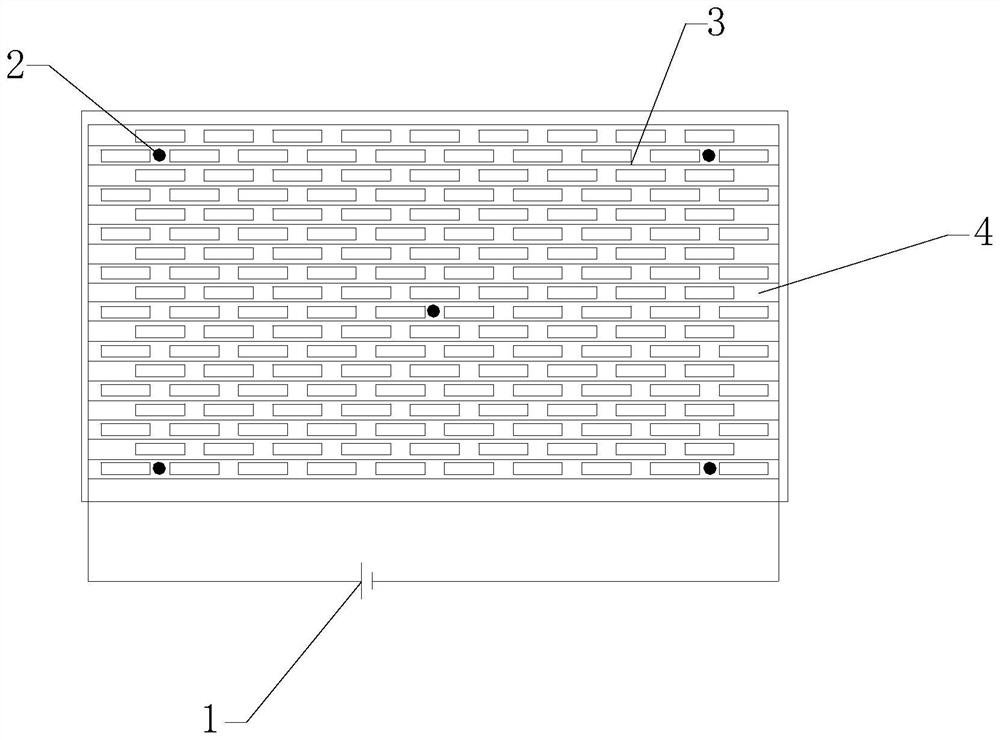

[0020] Such as figure 1 As shown, a self-heating coal mine drying flexible screen of the present invention includes a variable power supply 1, and the variable power supply 1 is electrically connected to a heating wire 3 through a wire, and the heating wire 3 is fixedly installed on a flexible screen 4. A temperature sensor 2 is fixedly installed on the surface of the screen cloth 4 .

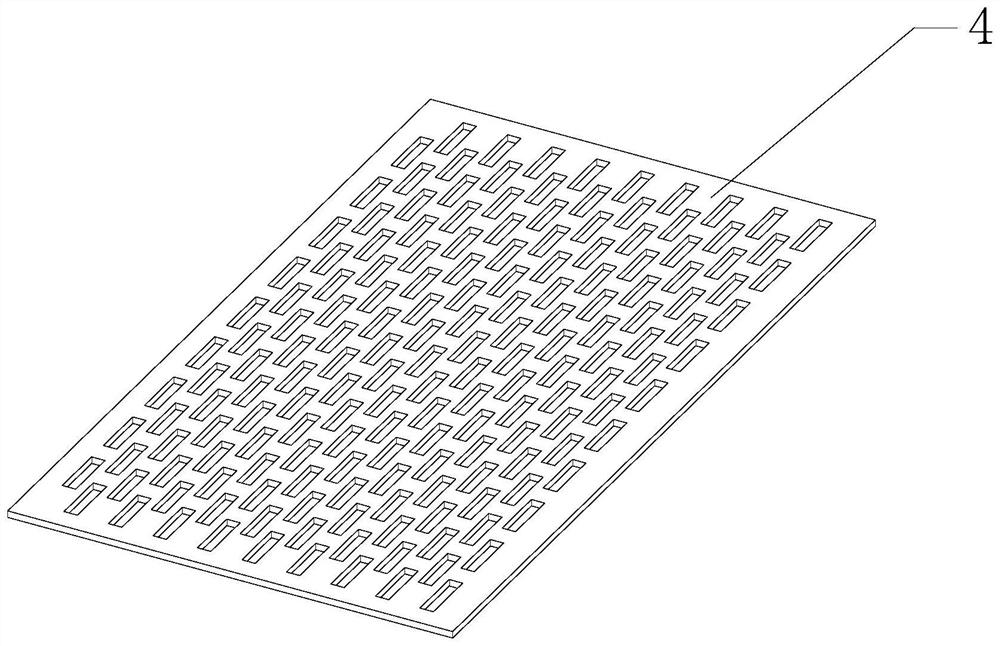

[0021] Further, in an embodiment of the present invention, as figure 2 As shown, the flexible screen 4 is made of polyurethane, and the heating wire 3 is evenly buried in the flexible screen 4 . The self-heating screen is to embed the heating wire 3 evenly inside the flexible screen 4, and the heating wire 3 is heated by electrification, and the current is controlled so that the maximum heating temperature is below 170°C. The coal mineral material screened on the screen surface is heated and dried to reduce the situation of particle agglomeration and viscosity increase that block the screen ...

Embodiment 2

[0023] Such as figure 2 and image 3 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: there are five temperature sensors 2, and the five temperature sensors 2 are respectively located at the four corners of the screen surface and the center of the screen surface, and can read the flexible screen 4 Surface temperature, the surface temperature of the flexible screen 4 is the average value of the temperature values of the five temperature sensors 2 . There are five temperature sensors arranged on the surface of the screen, distributed at the four corners and the center of the screen. The average temperature measured by the five temperature sensors 2 is the current heating temperature of the sieve surface, and the temperature of the sieve surface is set to be no higher than 170°C.

[0024] Further, in this embodiment, as figure 2 As shown, the heating temperature of the heating wire 3 can be adjusted by adjusting the voltage of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com