Fine ceramic production and processing equipment

A processing equipment and fine ceramics technology, applied in the field of fine ceramics production and processing equipment, can solve the problems of uneven spraying, affecting the appearance of fine ceramics, low efficiency, etc., and achieve the effect of reducing time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

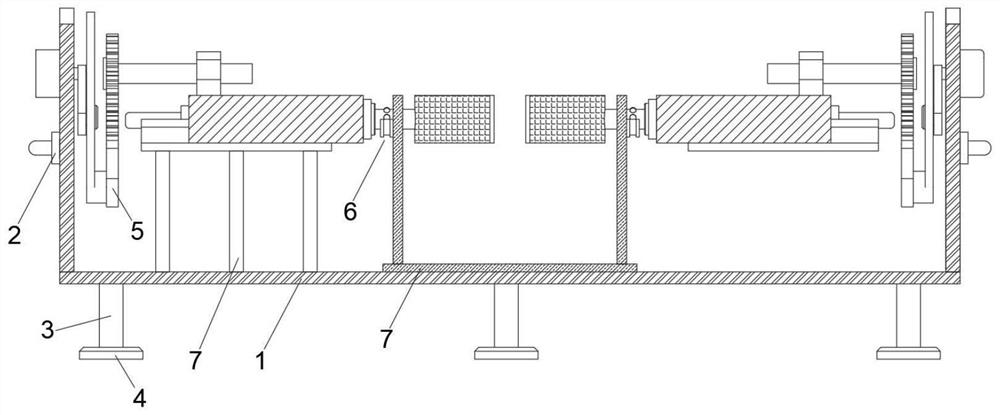

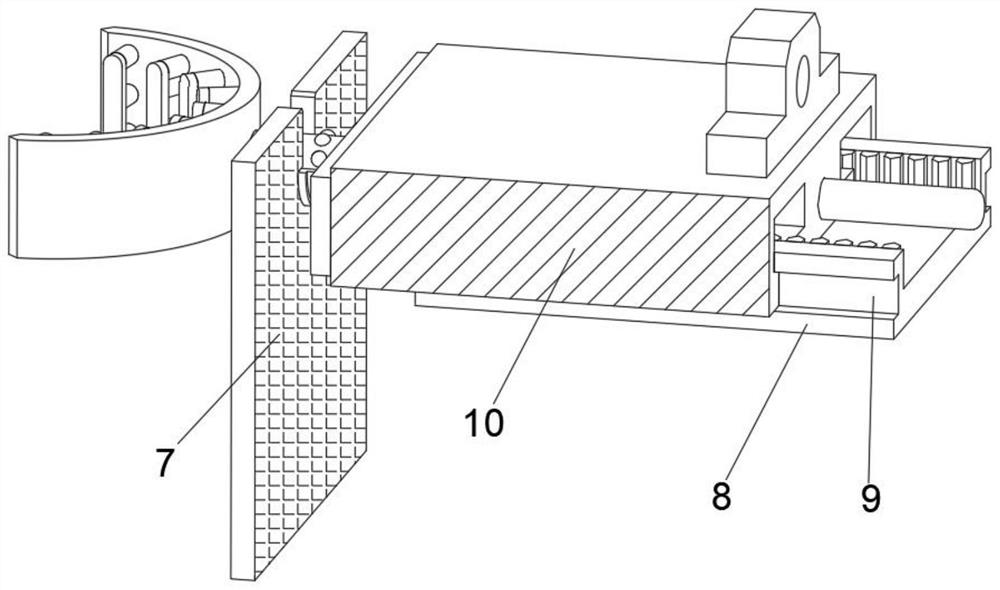

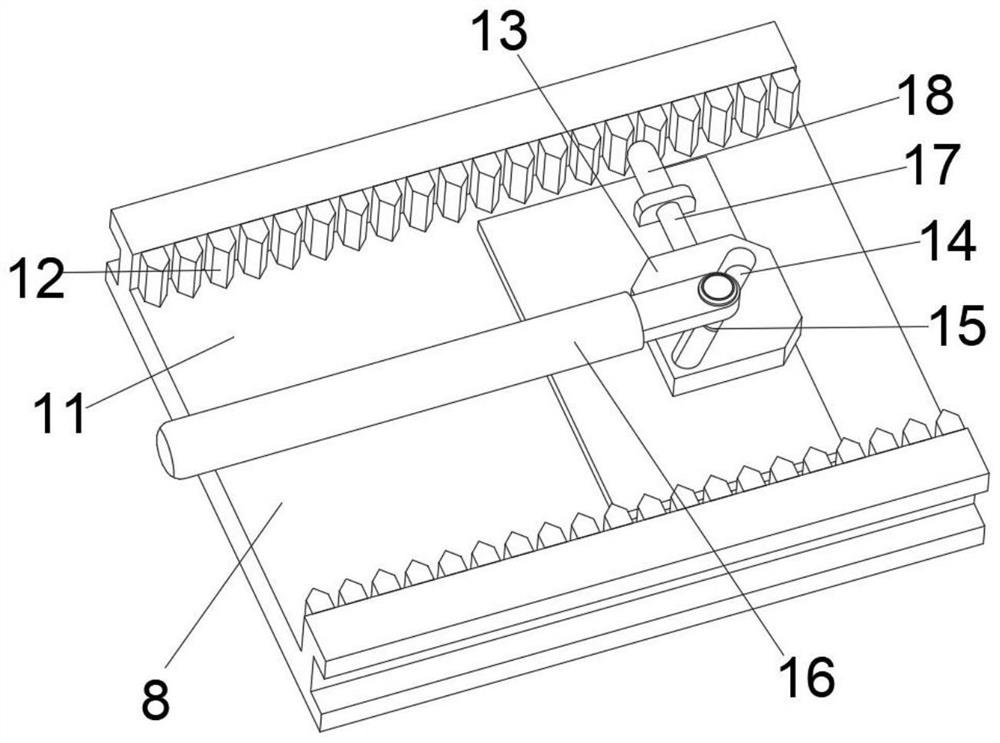

[0027] Such as Figure 1 to Figure 3 Shown:

[0028] The invention provides a fine ceramic production and processing equipment, wherein,

[0029] It includes a housing 1, the two sides of the housing 1 are symmetrically provided with armrest fixing blocks 2, and the four corners of the bottom end of the housing 1 are provided with support rods 3, and the support rods 3 are far away from the ends of the housing 1. A chassis 4 is provided at the top of the housing 1, and a fixing mechanism 5 is arranged symmetrically inside the housing 1. A glazing mechanism 6 is arranged between the fixing mechanisms 5, and a glazing box 7 is arranged on the inner top of the housing 1. , the fixed mechanism 5 includes a horizontal plate 8, the two sides of the horizontal plate 8 are symmetrically provided with a square groove 9, and the horizontal plate 8 is provided with a displacement plate 10, and the displacement plate 10 and the square groove 9, and the displacement plate 10 and the squa...

Embodiment 2

[0033] Such as figure 1 , Figure 4 to Figure 6 As shown, a fine ceramic production and processing equipment, wherein the glazing mechanism 6 includes a rotating shaft 19, the end of the rotating shaft 19 is provided with an annular plate 20, and the inside of the annular plate 20 is provided with a number of evenly distributed Buffer column 21, the buffer column 21 has a certain degree of elasticity, a U-shaped groove 22 is arranged in the glazing box 7, the rotating shaft 19 is in the U-shaped groove 22, and the glazing box The outer side of body 7 is symmetrically provided with semicircle snap ring 23, and described rotating shaft 19 is provided with some evenly distributed movable balls 24, and described movable ball 24 is embedded in described rotating shaft 19, and the maximum of described movable ball 24 The diameter is in the rotating shaft 19 , and the movable ball 24 fits in the semicircular snap ring 23 .

[0034]The side of the housing 1 is symmetrically provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com