Anti-whitening PU synthetic leather and preparation method thereof

A synthetic leather and anti-whitening technology, applied in transportation and packaging, textiles and papermaking, road vehicles, etc., can solve the problems of decreased wear performance, surface physical properties, and impact on user experience, etc., to achieve increased wear performance and high wear resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

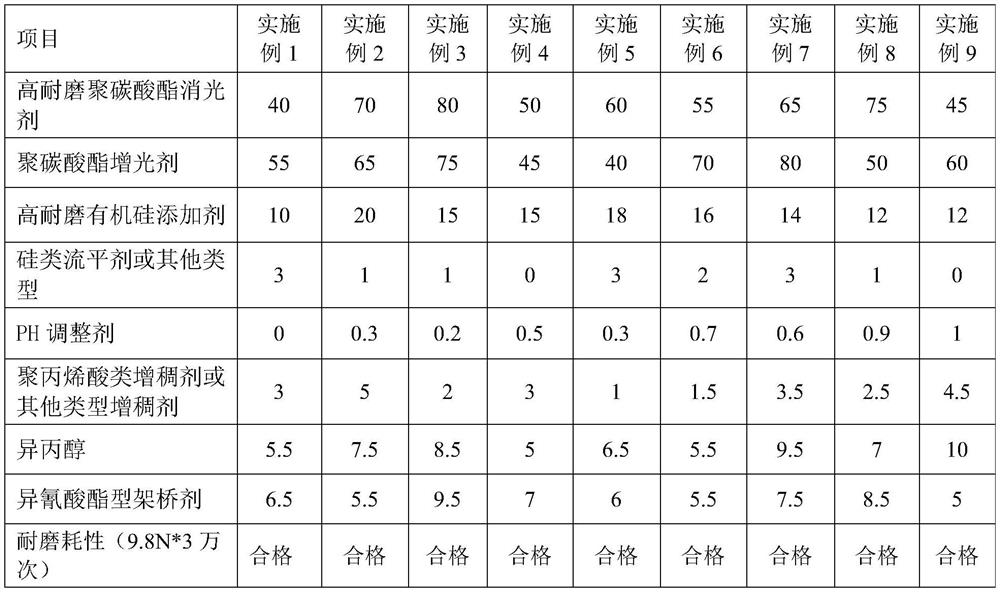

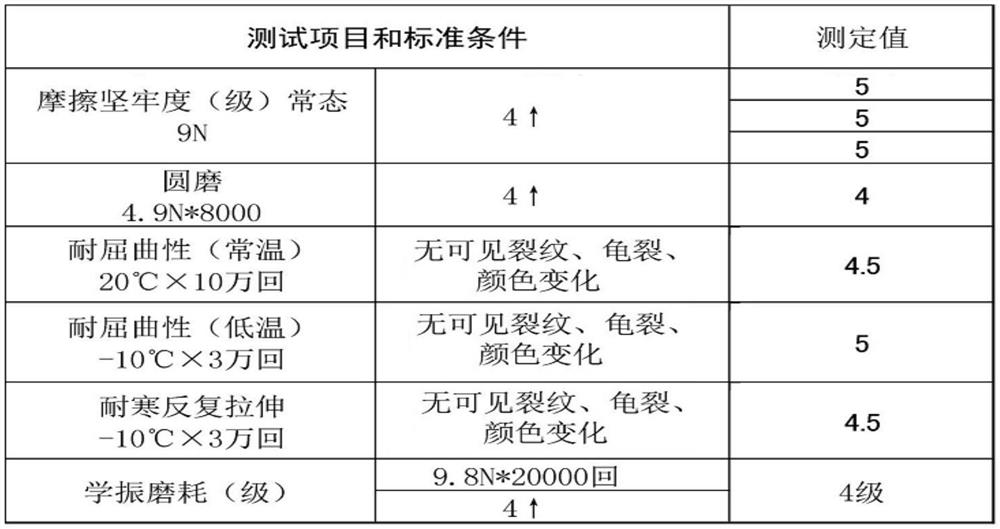

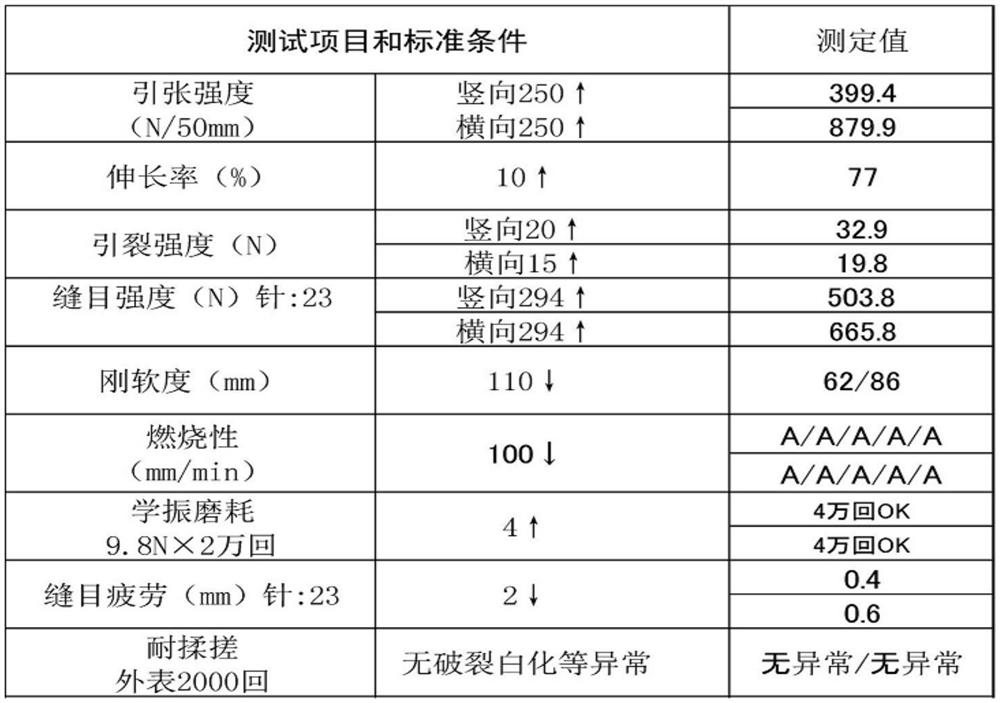

[0018] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail in conjunction with the following examples, so that those skilled in the art can fully understand the technical content of the present invention. It should be understood that the following examples are used to further illustrate the present invention, and should not be interpreted as limiting the protection scope of the present invention. Some non-essential improvements and adjustments made by those skilled in the art according to the above contents of the present invention all belong to the protection of the present invention scope. The specific method parameters and the like in the following example are only an example of the appropriate range, that is, those skilled in the art can make a selection within the appropriate range through the description herein, and are not limited to the specific values exemplified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com