Top calandria construction method and auxiliary device thereof

A construction method and technology of auxiliary devices, which are applied in the fields of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of heavy aerial work and inconvenience in the construction process and other issues to achieve the effect of reducing the workload and reducing the possibility of disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A construction method for top row pipes, comprising the following steps:

[0059] Build the model:

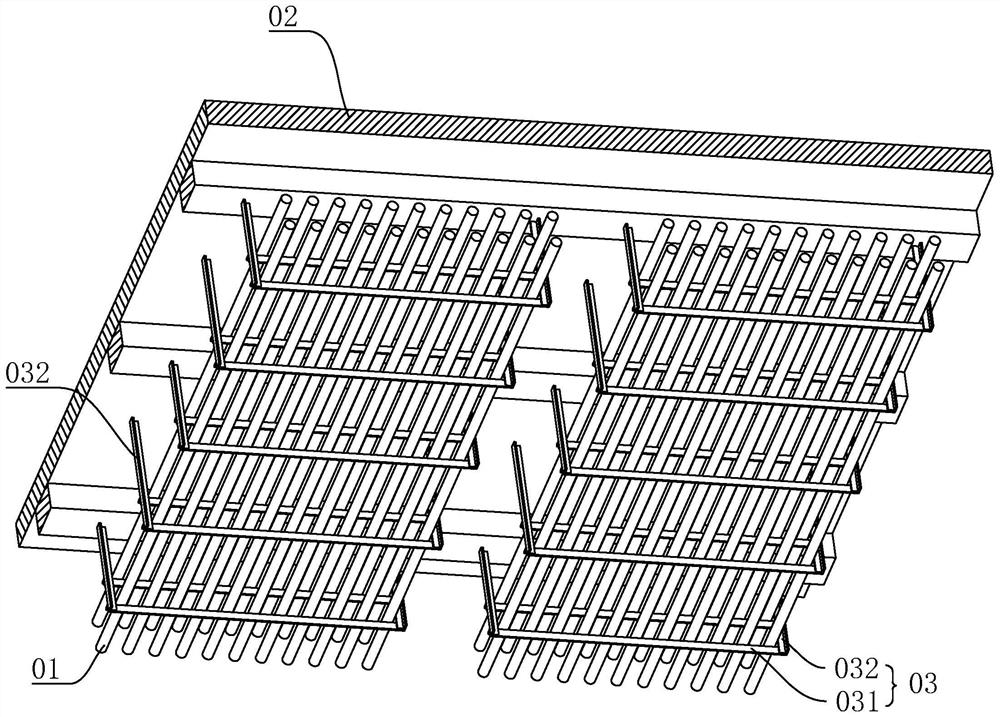

[0060] Design the building model after the construction of the top pipe 01, optimize the design through the BIM system, and determine the expected fixed position of the boom 032 of the support hanger 03 and the beam-slab structure 02; Fixed position, falls on the floor structure in beam-slab structure 02.

[0061] Poured beam and slab structure:

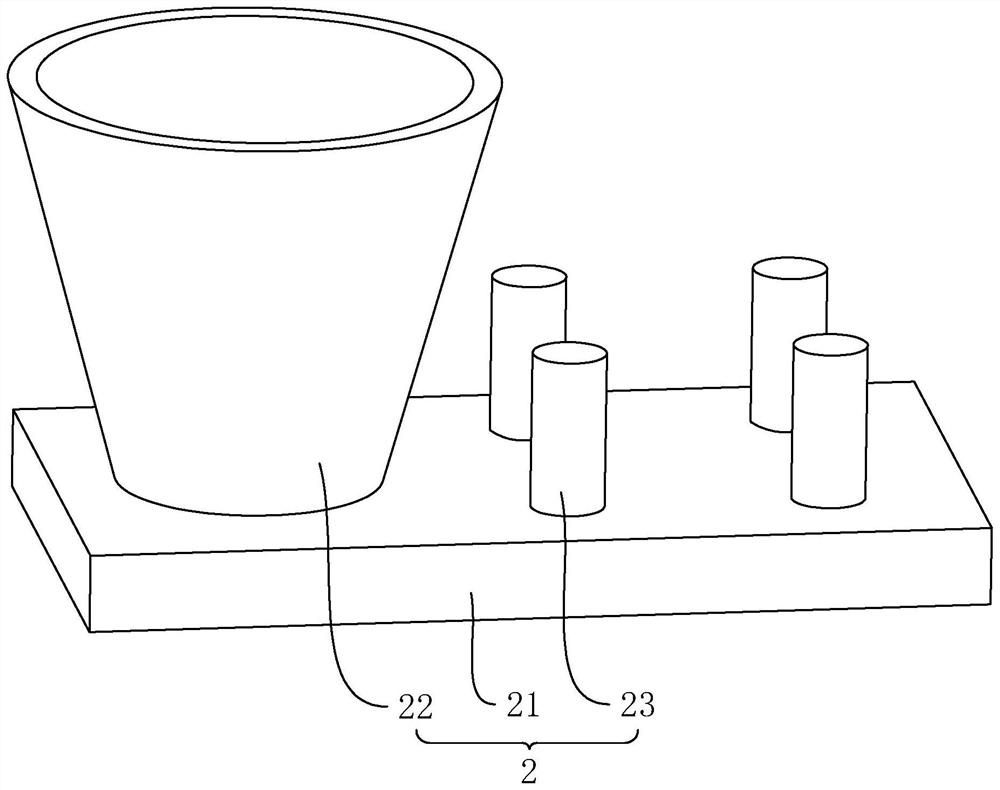

[0062] Determine the beam-slab structure 02 that needs to be installed with the top row of pipes 01, set a number of supporting devices 2, place the several supporting devices 2 on the bottom formwork of the formwork system before the beam-slab structure 02 of the layer to be installed is poured, and place a supporting device 2 on At the expected fixed position of a boom 032, concrete pouring is carried out to the formwork system of the beam-slab structure 02 on which the supporting device 2 has been placed.

[0063] refer t...

Embodiment 2

[0081] The difference between this embodiment and Embodiment 1 lies in that the shape of the reserved tube 22 is different.

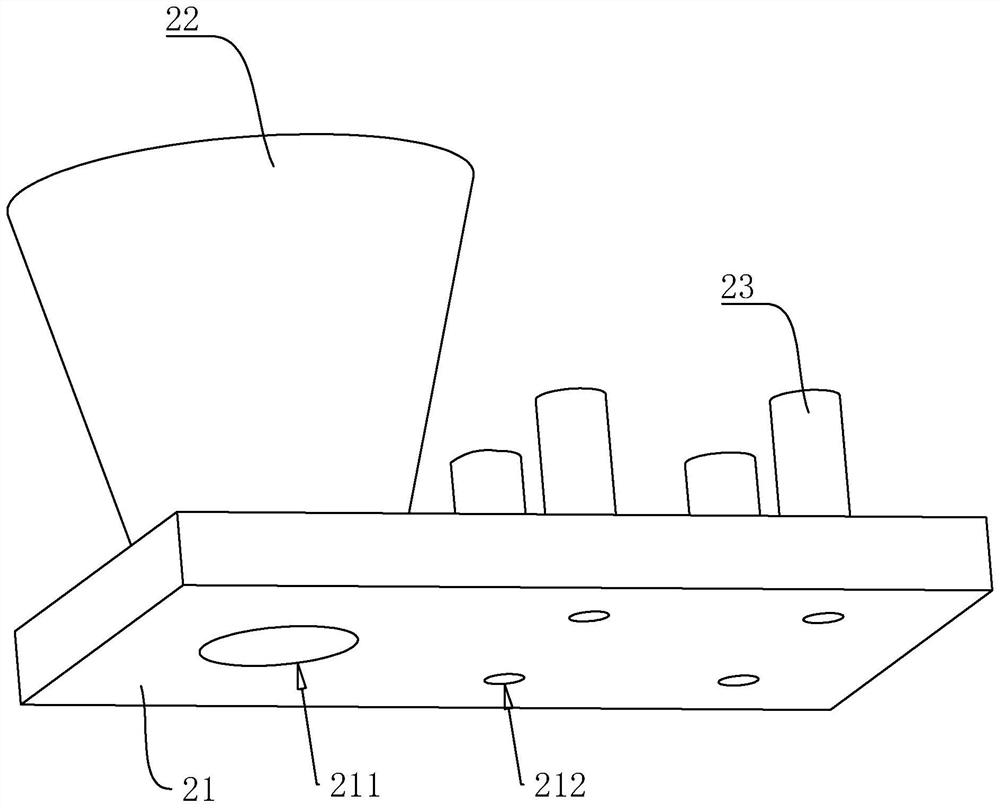

[0082] refer to Figure 10 , the reserved tube 22 includes a first tube 221 and a second tube 222, the first tube 221 and the second tube 222 are columnar tubes, the first tube 221 and the second tube 222 are coaxially welded and mutually connected, the first tube 221 and the second tube 222 have the same thickness, the inner diameter of the first tube 221 is larger than the inner diameter of the second tube 222, the second tube 222 is welded to the embedded plate 21, and the first tube 221 is located at The second tube 222 is away from the side of the embedded plate 21 .

[0083] The implementation principle of embodiment 2 is: through the through hole 1 formed by the reserved pipe 22, the upper port is larger than the lower port, and the concrete is poured, which reduces the possibility of the concrete block falling out of the through hole 1 after th...

Embodiment 3

[0085] The difference between this embodiment and Embodiment 1 lies in that the shape of the reserved pipe 22 and the corresponding construction method are different.

[0086] refer to Figure 11 , the reserved pipe 22 includes a fixed section 223 and a separation section 224, both of which are funnel-shaped round platform tubes, the ports at one end of the fixed section 223 and the separation section 224 are larger than the ports at the other end, and the ports of the fixed section 223 are smaller One end is welded on the embedded plate 21, the separation section 224 is installed on the side of the fixed section 223 away from the embedded plate 21, the smaller end of the separation section 224 port is inserted into the larger end of the fixed section 223 port, the separation section 224 and The fixed section 223 can be disassembled; the construction impact caused by the difference between the height of the reserved pipe 22 and the thickness of the concrete layer can be avoide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com