Concrete member reinforcing method and concrete reinforcing structure

A concrete reinforcement and concrete technology, applied in building construction, construction, building maintenance, etc., can solve problems such as decreased bond strength, peeling damage and deterioration of bond interface, and achieves increasing bond area and improving strength utilization. and reinforcement effect, the effect of increasing the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

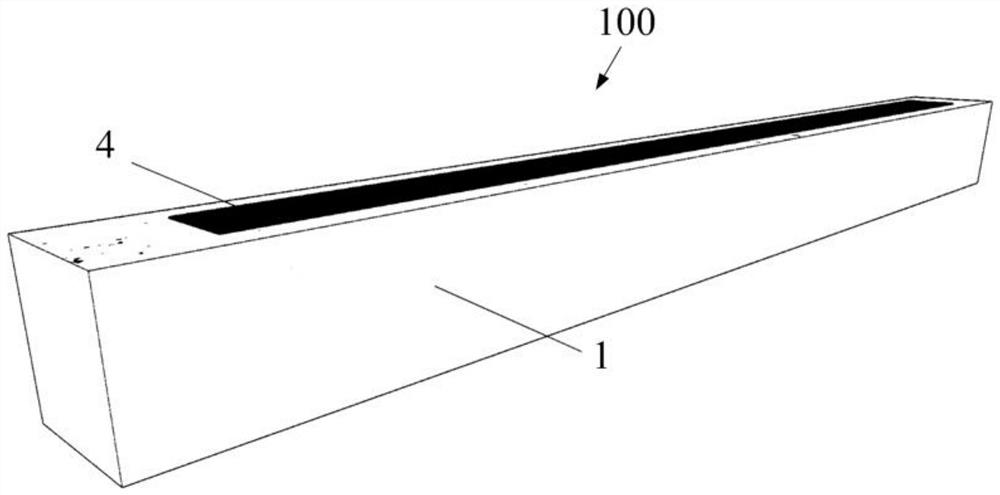

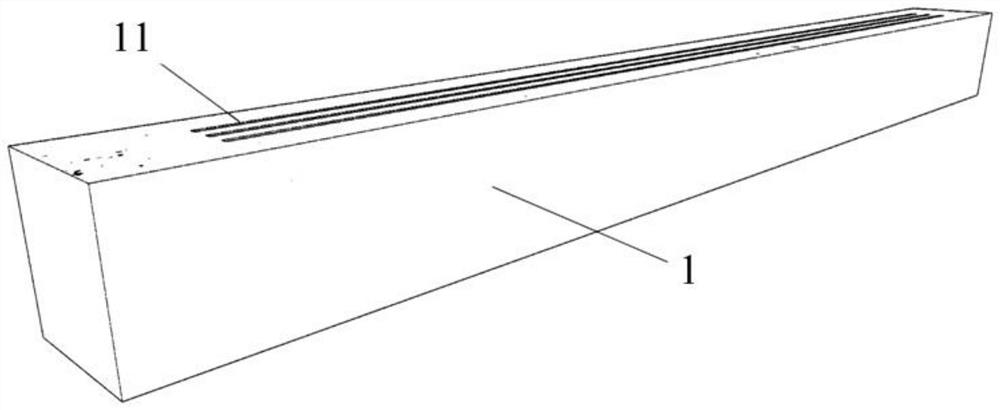

[0033] like Figure 1-3 As shown, the present embodiment provides a concrete component reinforcement method, comprising the following steps:

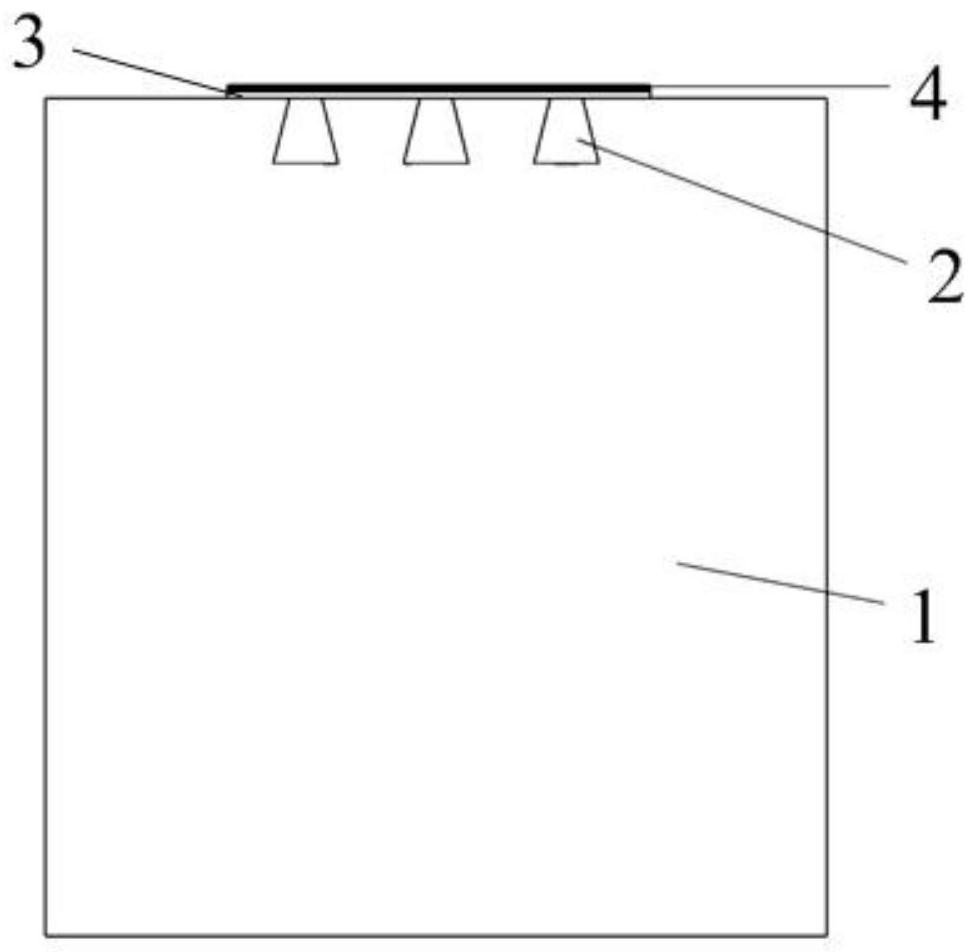

[0034] Step 1, opening at least one groove 11 on the first surface of the concrete member 1;

[0035] Step 2, filling the first adhesive into each groove 11 and forming each first adhesive body 2;

[0036] Step 3, coating the second adhesive on the first surface and the top surface of each first bonding body 2 to form a second bonding body 3;

[0037] Step 4: Paste the fiber-reinforced composite material strip 4 on the surface of the second bonded body 3 away from the first bonded body 2 .

[0038] Therefore, the concrete member reinforcement method provided in this embodiment, such as Figure 1-3 As shown, by filling the first adhesive into the grooves 11 opened on the first surface of the concrete member 1, and coating the second adhesive on the surface of the concrete member 1 provided with each groove 11 And on the top surface o...

Embodiment 2

[0046] This embodiment provides a concrete reinforcement structure 100, such as Figure 1-3As shown, comprising a concrete member 1, a first bonding body 2, a second bonding body 3 and a fiber reinforced composite material strip 4, at least one groove 11 is opened on the first surface of the concrete member 1, and the first bonding agent It is used to fill the grooves 11 to form the first adhesive bodies 2 , and the second adhesive is used to coat the first surface of the concrete member 1 with the grooves 11 and the first adhesive bodies 2 . A second bonding body 3 is formed on the top surface, and the fiber-reinforced composite material strip 4 is used to stick on the surface of the second bonding body 3 away from the first bonding body 2 .

[0047] In the reinforcement structure of the concrete member 1 provided in this embodiment, the first adhesive is filled into the grooves 11 opened on the first surface of the concrete member 1, and the second adhesive is applied to eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com