Flexible pipeline device for mixed heating gas jet supply of hypersonic wind tunnel

A hypersonic, heating gas technology, applied in the direction of hose connection devices, measuring devices, pipeline heating/cooling, etc., can solve the problems of aircraft flow field interference damage, impact resistance limitation, impact measurement results, etc., to solve the problem of heat preservation and The effect of temperature imbalance, reducing resistance and pressure loss, and preventing excessive temperature of the outer wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

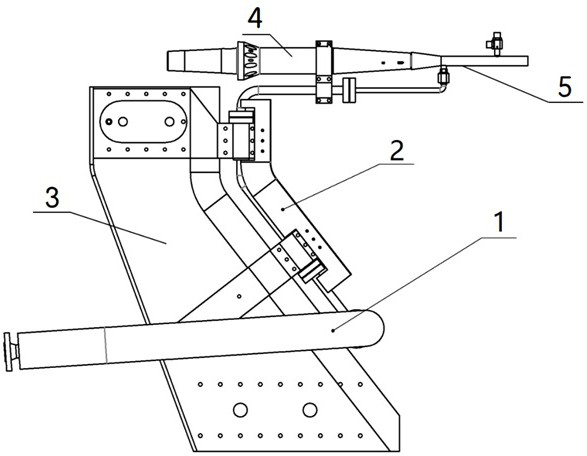

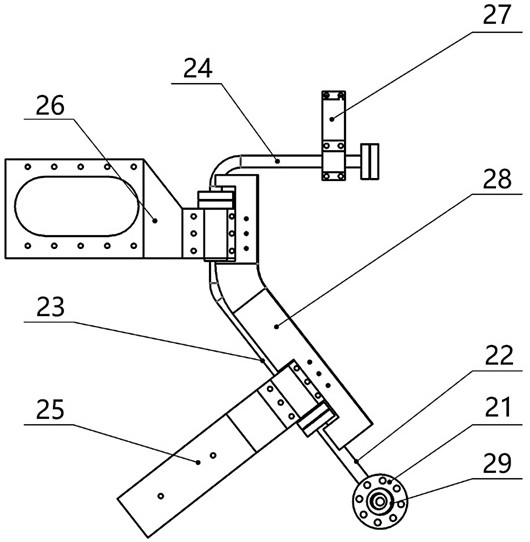

[0046] The flexible pipeline device used in the hypersonic wind tunnel for mixed heating gas jet supply in this embodiment is installed in the hypersonic wind tunnel. The top of the angle-of-attack mechanism of the hypersonic wind tunnel is fixed with a model support device 4, the front end of the model support device 4 is equipped with a test device 5, and the test device 5 is provided with a flange connecting the outlet end of the hard pipe.

[0047] The hard tube in this embodiment is divided into three sections, namely hard tube I22, hard tube II23, and hard tube III24. The corresponding mechanism machete splints are divided into two groups, namely splint I25 and splint II26. Tube I22 and splint II26 are used to fix hard tube II23. The test device has one set of splints, namely splint III27, and splint III27 is used to fix hard tube III24. The splint I25 and the splint II26 are fixed on the side wall of the mechanism machete 3 by countersunk head screws, and the splint III...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com