Wall thickness and high temperature on-line measurement system for hot-rolled steel pipe

A measuring system and technology for steel pipes, which are used in length measuring devices, metal rolling, metal rolling, etc., can solve the problem of inability to realize high-temperature online measurement of the wall thickness of hot-rolled steel pipes, so as to improve measurement accuracy, real-time measurement, and save money. Labor cost, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The above description is only an overview of the technical solution of the present invention. In order to better understand the technical means of the present invention, it can be implemented according to the contents of the description, and in order to make the above and other purposes, features and advantages of the present invention more obvious and understandable , the specific embodiments of the present invention are enumerated below.

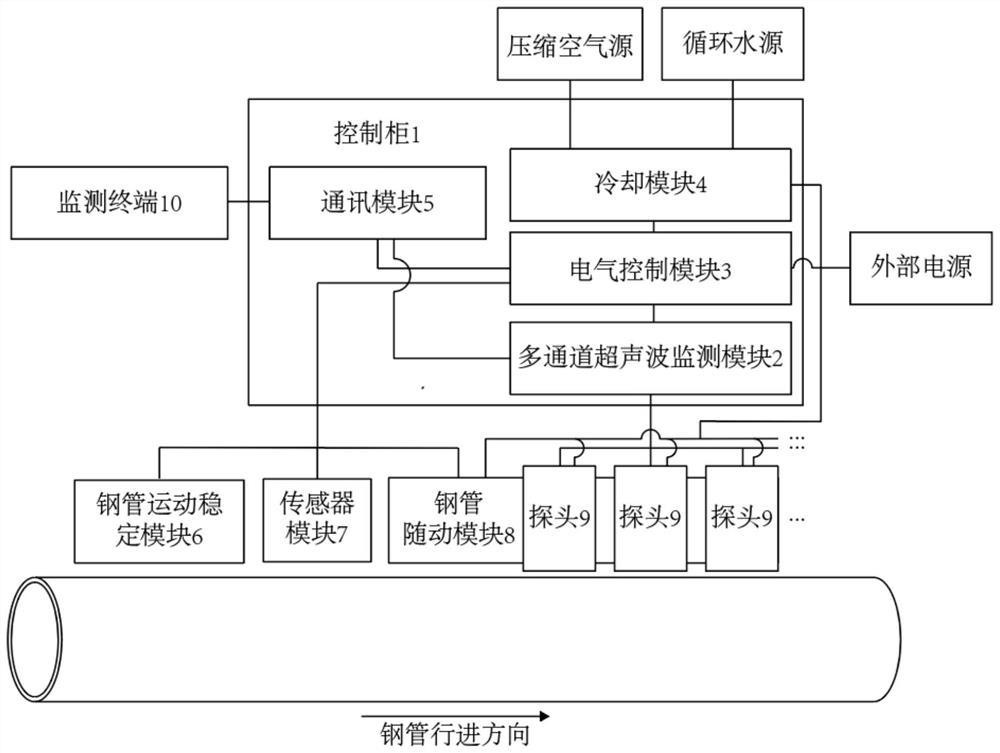

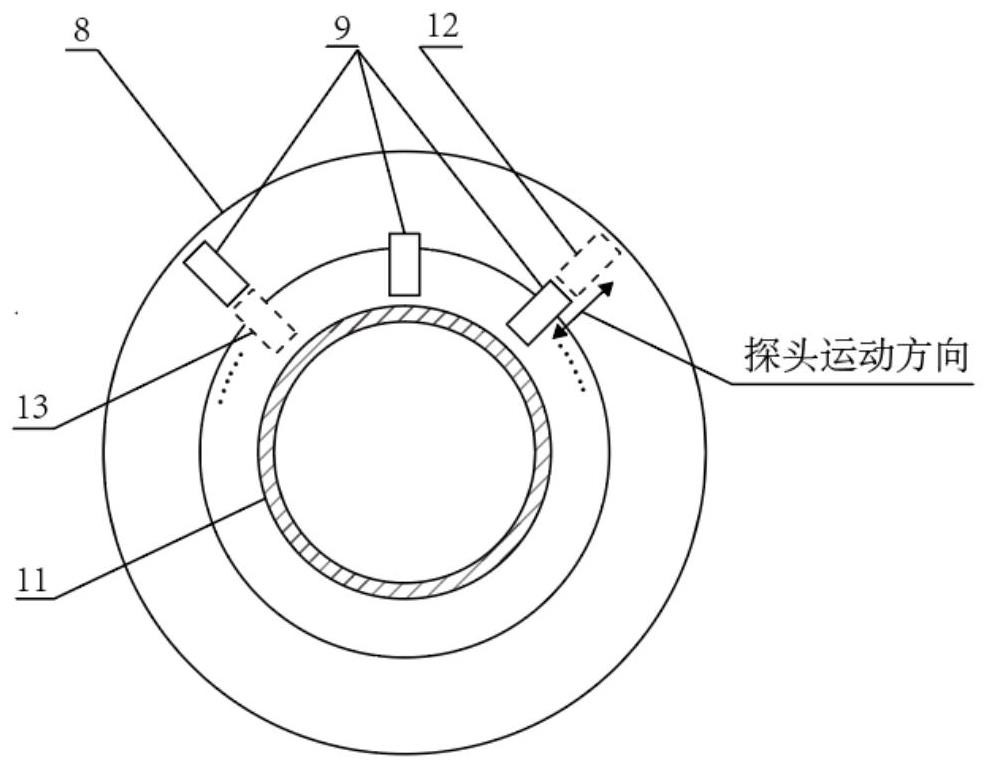

[0020] Such as figure 1 As shown, the present invention includes a control cabinet 1, a multi-channel ultrasonic monitoring module 2, an electrical control module 3, a cooling module 4, a communication module 5, a steel pipe movement stabilization module 6, a sensor module 7, a steel pipe follow-up module 8, a probe group and a monitoring terminal 10;

[0021] The monitoring terminal 10 is installed and arranged in the monitoring room. Through the monitoring terminal 10, the wall thickness monitoring results can be viewed and analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com