Polishing and derusting equipment for intelligent manufacturing of steel structure

A technology of intelligent manufacturing and steel structure, which is applied in the direction of manufacturing tools, metal processing equipment, used abrasive processing devices, etc., can solve the problems of not being able to completely remove surface rust stains, increase the burden on operators, and reduce workload, etc., to achieve It is not easy to drift away, improves the accuracy of rust removal, and reduces the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

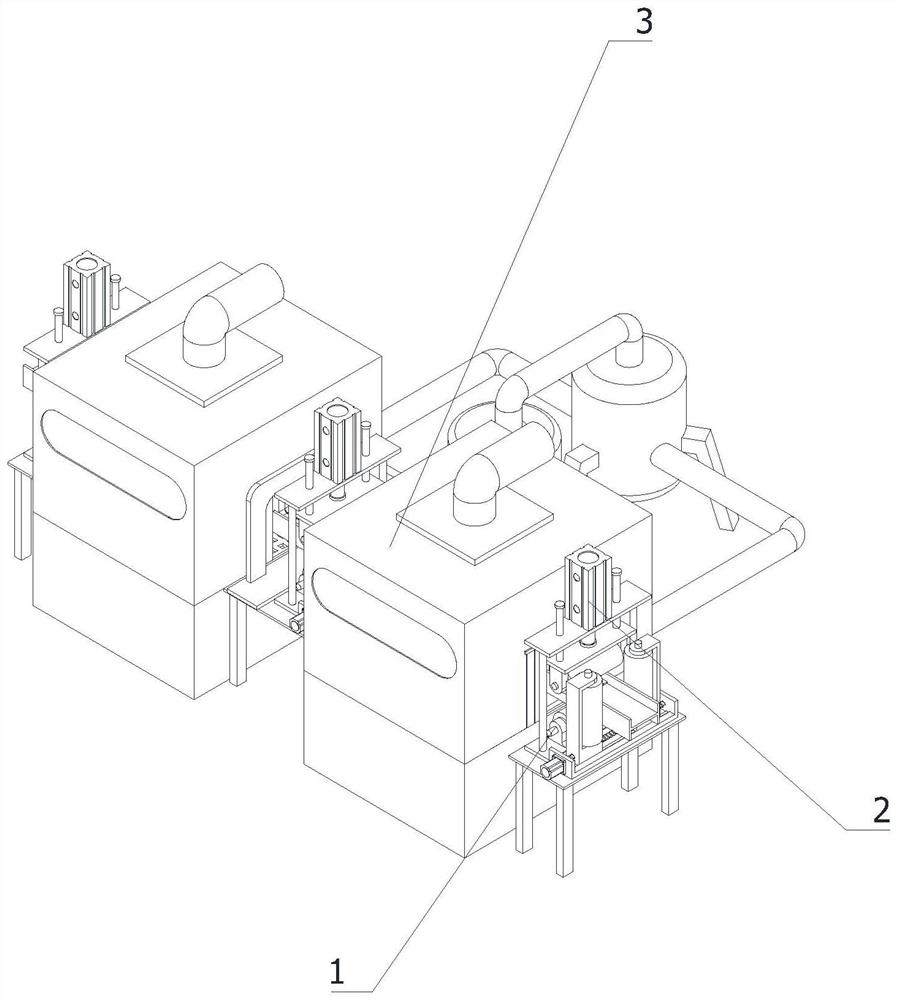

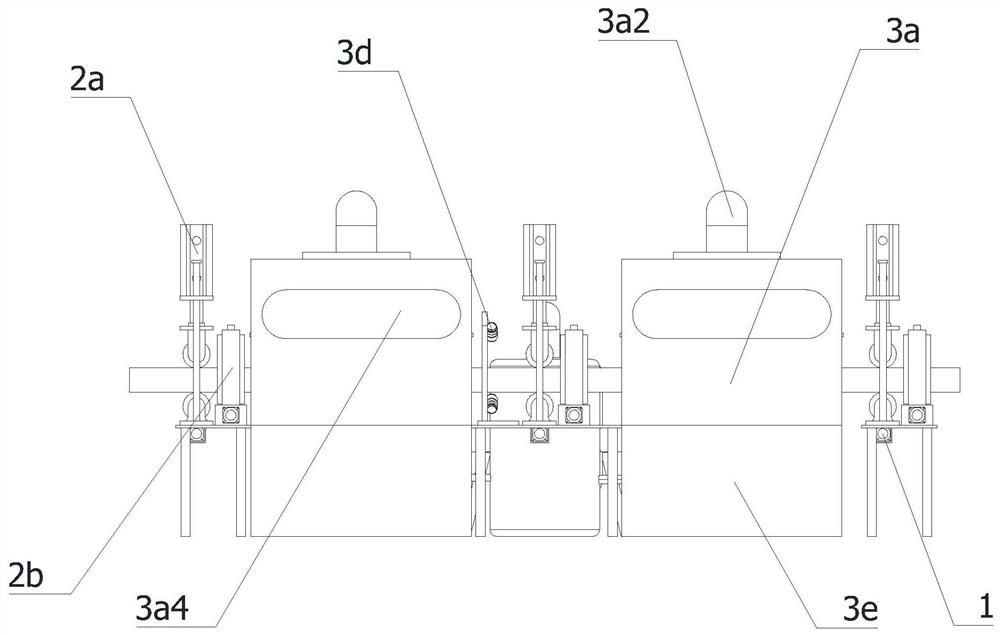

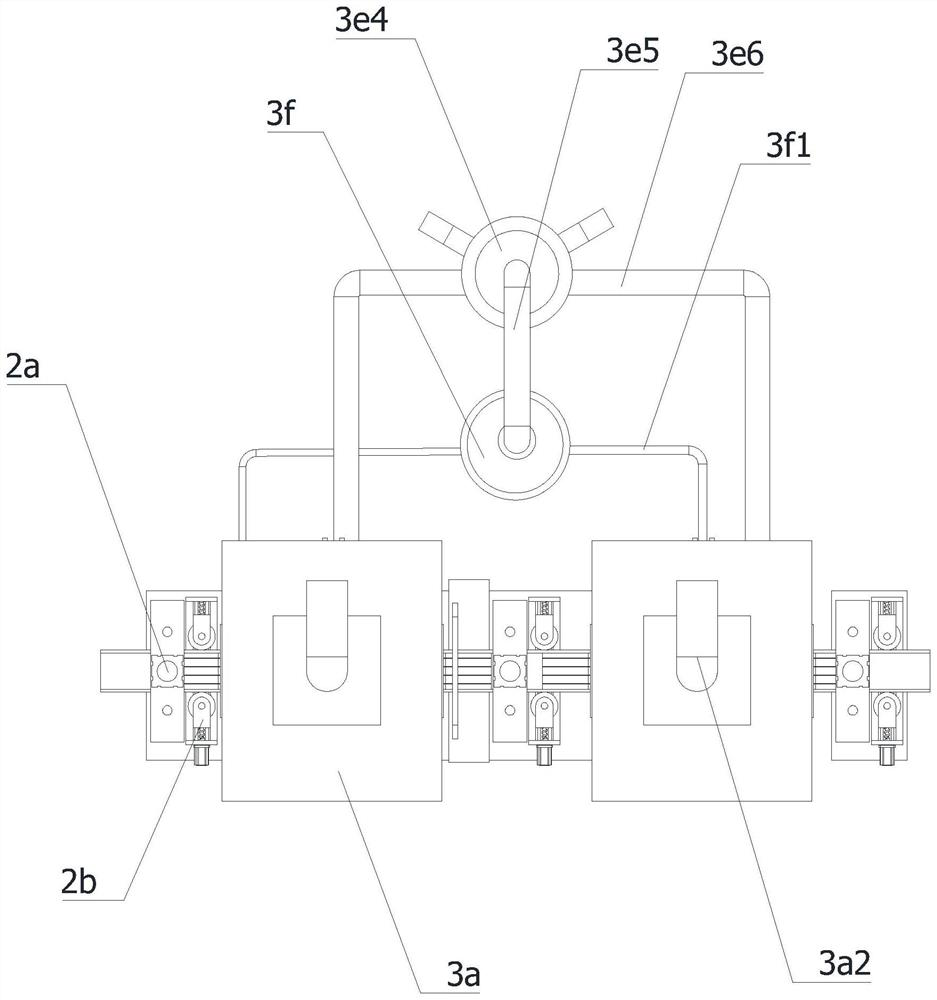

[0036] Such as Figure 1-11 As shown, the present application provides: a polishing and derusting equipment for steel structure intelligent manufacturing, including a material transfer mechanism 1, a positioning mechanism 2 and a derusting device 3 arranged on it, and the derusting device 3 includes a rust removal device for steel structure workpieces The first sandblasting assembly 3b for the first derusting, the second sandblasting assembly 3c for the second derusting of the steel structure workpiece, the first sandblasting assembly 3b and the second sandblasting assembly 3c for storage A raw material box 3f for abrasives, a detection mechanism 3d for detecting surface rust stains on steel structural w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com