Polycarboxylic acid high-performance water reducing agent and preparation process thereof

A polycarboxylic acid, high-performance technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor concrete stability and high water-reducing efficiency of water-reducing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A polycarboxylic acid high-performance water reducer, comprising the following raw materials in parts by weight: 40 parts of modified polycarboxylic acid, 3 parts of sodium hydroxide, 8 parts of hydroxypropyl starch ether, 5 parts of glycerin, and 60 parts of water;

[0044] Modified polycarboxylic acid is made by following steps:

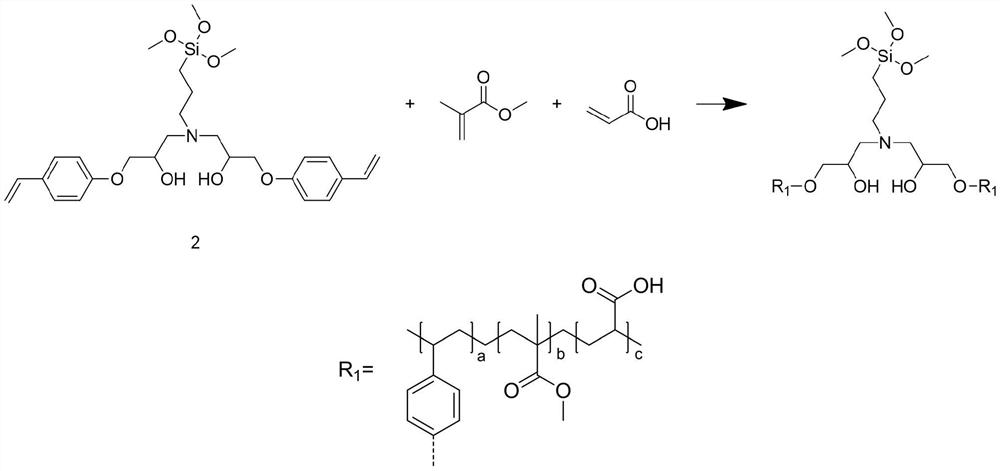

[0045] Mix methoxypolyoxyethylene ether and deionized water evenly, stir at a speed of 150r / min and a temperature of 40°C, and add modified resin, modified monomer, sodium methacrylate, Ammonium persulfate was raised to a temperature of 70° C., and after 3 hours of reaction, the pH value of the reaction solution was adjusted to be neutral, and the deionized water was distilled off to obtain a modified polycarboxylic acid.

[0046] Modified resin is made by the following steps:

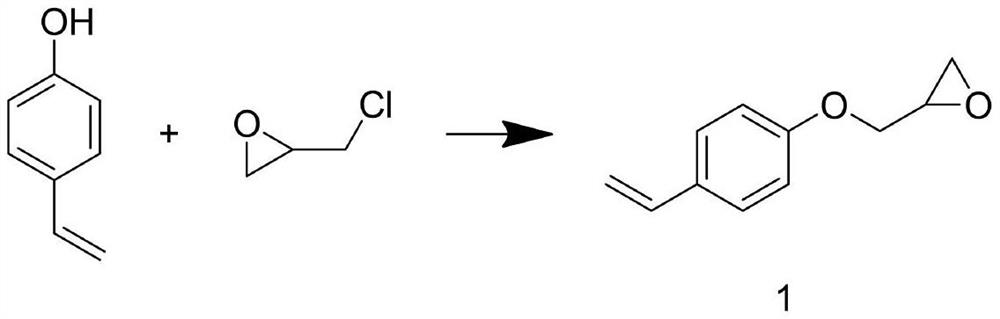

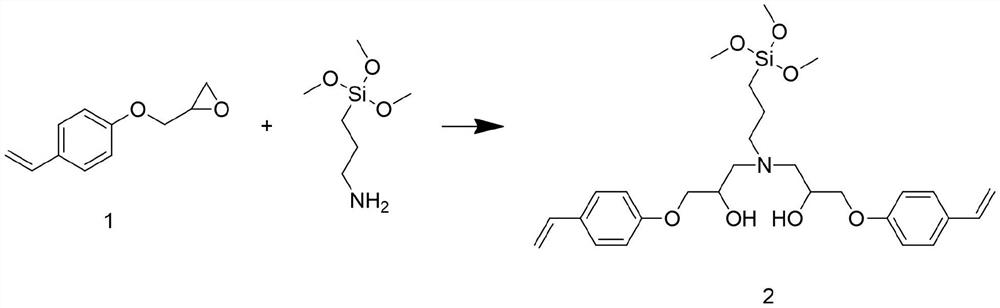

[0047] Step B1: Dissolve p-hydroxystyrene in N,N-dimethylformamide, add sodium hydroxide and epichlorohydrin, and carry out the reaction for 1 hour at a rotation sp...

Embodiment 2

[0055] A polycarboxylic acid high-performance water reducer, comprising the following raw materials in parts by weight: 45 parts of modified polycarboxylic acid, 4 parts of sodium hydroxide, 9 parts of hydroxypropyl starch ether, 6 parts of glycerin, and 70 parts of water;

[0056] Modified polycarboxylic acid is made by following steps:

[0057] Mix methoxypolyoxyethylene ether and deionized water evenly, stir at a speed of 180r / min and a temperature of 45°C and add modified resin, modified monomer, sodium methacrylate, ammonium persulfate, the temperature was raised to 75° C., and after 4 hours of reaction, the pH of the reaction solution was adjusted to be neutral, and the deionized water was distilled off to obtain a modified polycarboxylic acid.

[0058] Modified resin is made by the following steps:

[0059] Step B1: Dissolve p-hydroxystyrene in N,N-dimethylformamide, add sodium hydroxide and epichlorohydrin, and react for 1.3 hours at a speed of 180r / min and a temperat...

Embodiment 3

[0067] A polycarboxylic acid high-performance water reducer, comprising the following raw materials in parts by weight: 50 parts of modified polycarboxylic acid, 5 parts of sodium hydroxide, 10 parts of hydroxypropyl starch ether, 8 parts of glycerin, and 80 parts of water;

[0068] Modified polycarboxylic acid is made by following steps:

[0069] Mix methoxypolyoxyethylene ether and deionized water evenly, stir at a speed of 200r / min and a temperature of 50°C, and add modified resin, modified monomer, sodium methacrylate, Ammonium persulfate was raised to a temperature of 80° C., and after 5 hours of reaction, the pH value of the reaction solution was adjusted to be neutral, and the deionized water was distilled off to obtain a modified polycarboxylic acid.

[0070] Modified resin is made by the following steps:

[0071] Step B1: Dissolve p-hydroxystyrene in N,N-dimethylformamide, add sodium hydroxide and epichlorohydrin, and react for 1.5 hours at a speed of 200r / min and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com