Foldable prism structure with rotary motion

A technology of rotating motion and prisms, which is applied in the direction of building components, residential buildings, building structures, etc., can solve the problems of small folding and unfolding ratios, and achieve easy processing and manufacturing and mass production, simple structure, and large folding and unfolding ratios. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

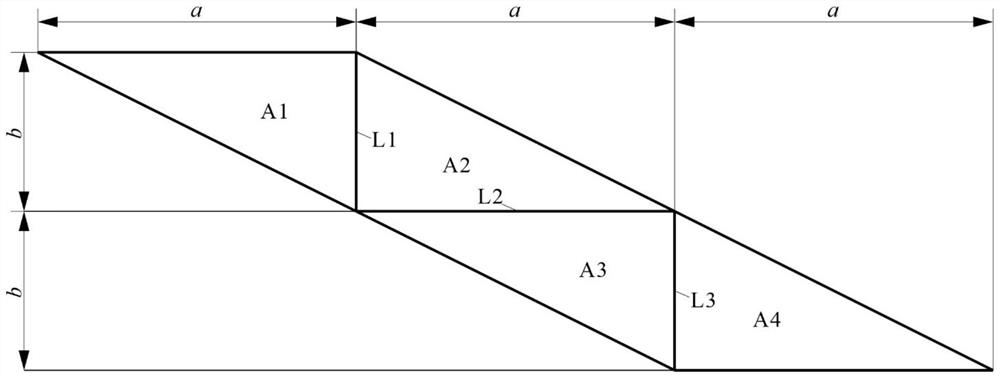

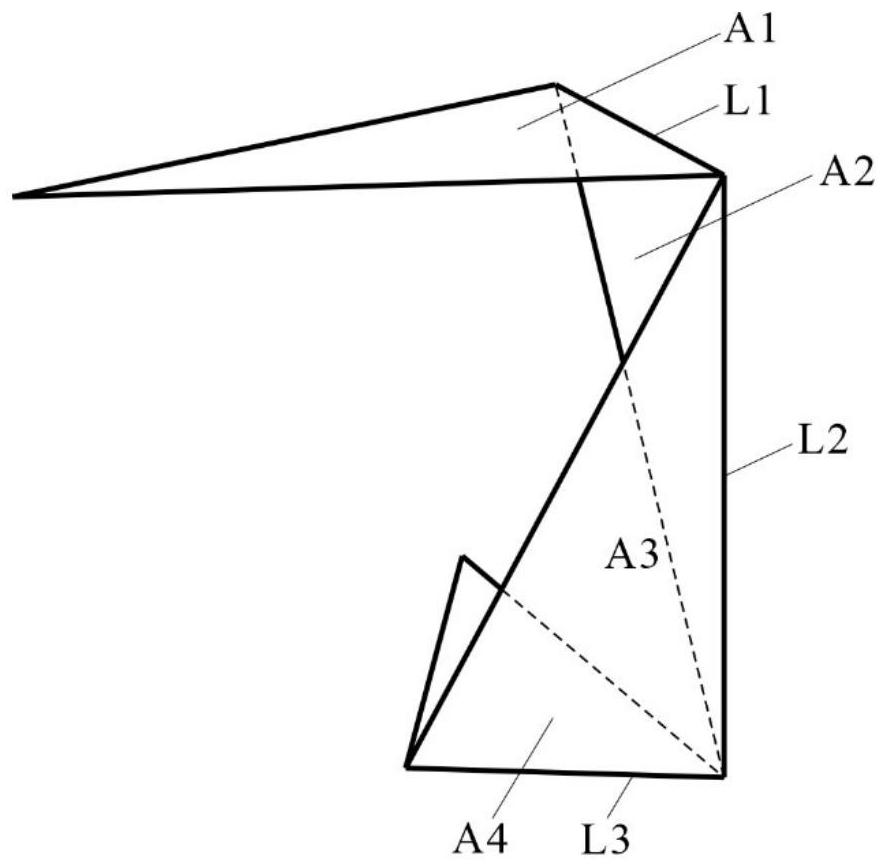

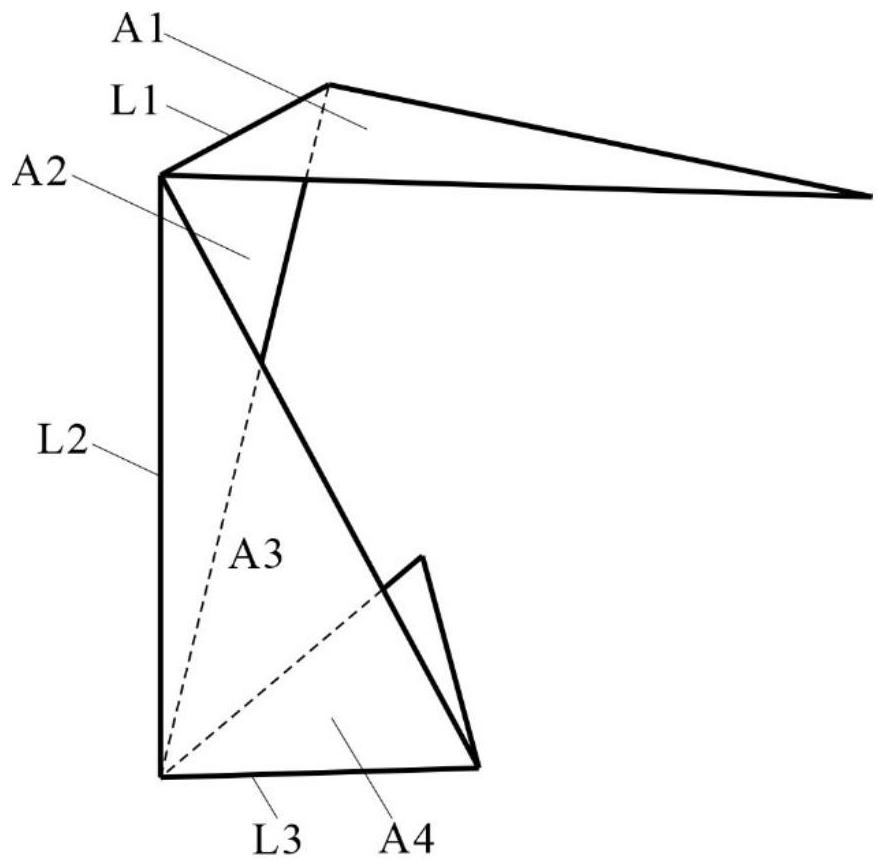

[0044] Picture 1-1 It is the module expansion pattern of the foldable prism structure in the present invention, and the pattern is composed of four congruent triangles whose right-angled side lengths are a and b, and the first, second, third and third sides of the four congruent triangles are The fourth surfaces are A1, A2, A3 and A4 respectively; the first surface A1 is adjacent to the second surface A2 and is connected to each other through the first rotating pair L1, and the second surface A2 is adjacent to the third surface A3 and is connected through the second rotating pair The pair L2 is connected to each other, the third surface A3 is adjacent to the fourth surface A4 and connected to each other through the third rotating pair L3, and the center line of the rotating pair is folded outward around the solid line to form a convex shape, forming a folded shape of the module such as Figure 1-2 As shown, a module of a foldable prism structure is formed in this way. Mirror ...

Embodiment 2

[0057] Such as Figure 6-1 As shown, this embodiment provides an unfolded structure of a foldable quadrangular prism with rotational movement, including a top surface C1, a bottom surface C2 and four modules II1, II2, II3, II4. The top surface C1 and the bottom surface C2 are congruent squares, and the structural parameters of the four modules II1, II2, II3, and II4 are the same.

[0058] The top surface C1 and the bottom surface C2 are arranged in parallel, respectively serving as the upper and lower bottom surfaces of the foldable prism structure; the top surface C1 is adjacent to the first surface of the module II1 and connected to each other through the upper turning pair N1 of the module II1, in a counterclockwise order, The top surface C1 is adjacent to the first surface of the module II2 and is connected to each other through the upper turning pair N2 of the module II2, and the top surface C1 is adjacent to the first surface of the module II3 and is connected to each ot...

Embodiment 3

[0066] Such as Figure 10-1 As shown, this embodiment provides a structure in the unfolded state of a foldable pentagonal prism with rotational movement, including a top surface D1, a bottom surface D2 and five modules III1, III2, III3, III4, III5. The top surface D1 and the bottom surface D2 are congruent regular pentagons, and the structural parameters of the five modules III1, III2, III3, III4, and III5 are the same.

[0067]The top surface D1 and the bottom surface D2 are arranged in parallel, respectively serving as the upper and lower bottom surfaces of the foldable prism structure; the top surface D1 is adjacent to the first surface of the module III1 and connected to each other through the upper rotation pair O1 of the module III1, in a counterclockwise order, The top surface D1 is adjacent to the first surface of the module III2 and connected to each other through the upper turning pair O2 of the module III2, and the top surface D1 is adjacent to the first surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com