Aerostatic bearing based on lotus root-shaped directional porous throttling

A gas static pressure, lotus-shaped technology, applied in the transmission field, can solve the problem that the gas static pressure bearing cannot meet the extreme precision processing requirements of optical components, and achieve the effect of reducing motion friction and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

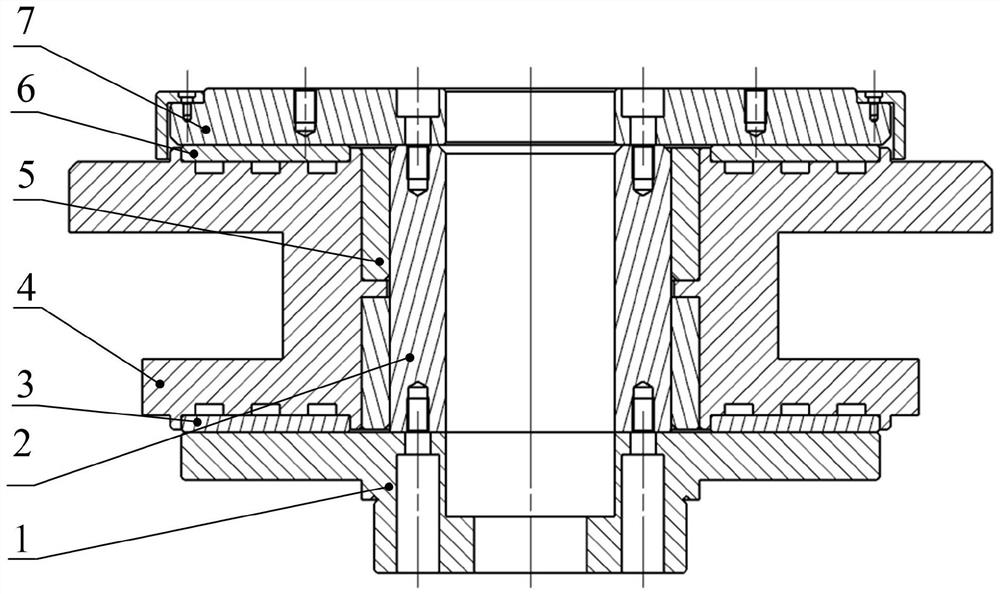

[0048] Such as figure 1 As shown, an aerostatic bearing based on a lotus-shaped directional porous throttle includes a throttle mount 4, a rotating shaft 2, a first thrust plate 7, a second thrust plate 1, and a throttle group.

[0049] The throttle mount 4 has a first plane and a second plane parallel to each other, such as figure 1 As shown, set the first plane as the upper side shown in the figure, and the second plane as the lower side shown in the figure, then the restrictor is installed on a parallel upper side and lower side, and is installed inside the restrictor mounting seat 4 An installation through hole perpendicular to the first plane and the second plane, the installation through hole is used for installation and rotation.

[0050] The rotating shaft 2 is arranged in the installation through hole of the throttle mounting seat 4, and the central axis of the rotating shaft 2 coincides with the central axis of the installation through hole; the rotating shaft 2 can...

Embodiment 2

[0059] This embodiment illustrates the structure of the restrictor group in the first embodiment.

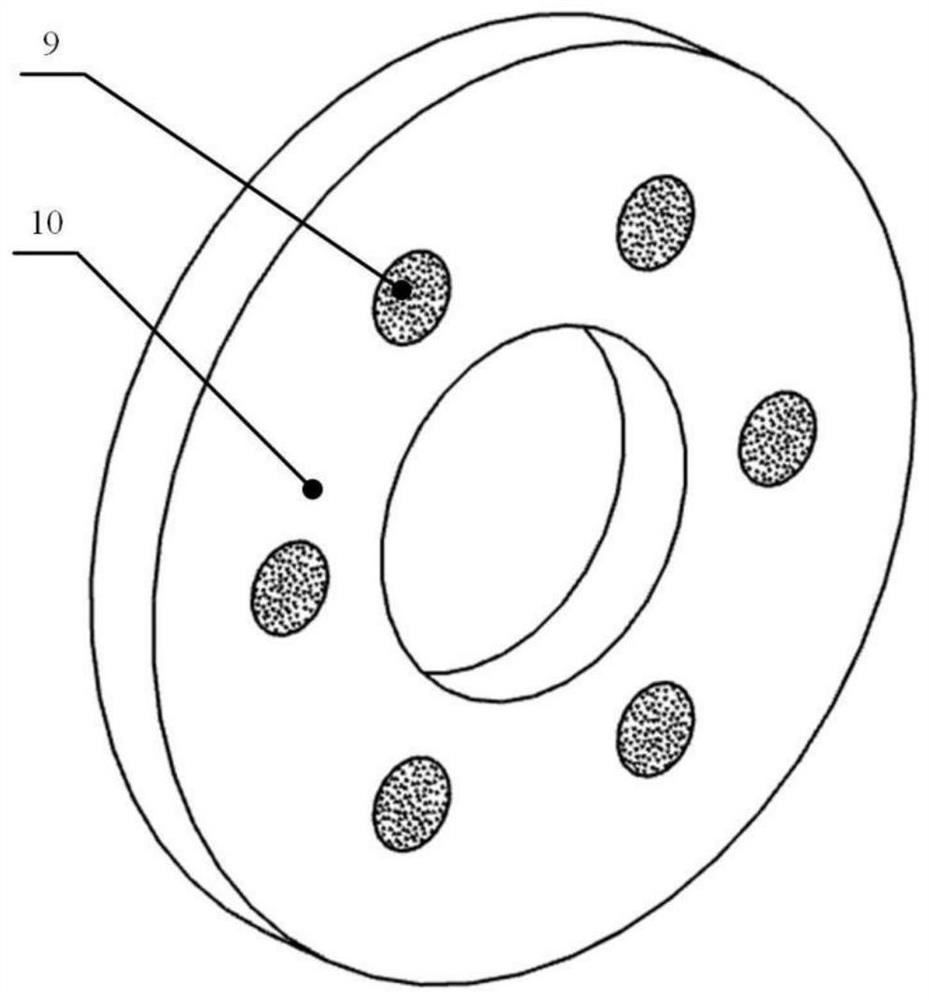

[0060] The restrictor group includes a radial restrictor 5 , a first thrust restrictor 6 and a second thrust restrictor 3 .

[0061] The radial restrictor 5 is arranged between the installation through hole and the rotating shaft 2, and the radial restrictor 5 is fixedly connected to the inner surface of the installation through hole, and its purpose is to provide a high-pressure air film between the installation through hole and the rotating shaft 2 , so that there is no contact between the outer surface of the rotating shaft 2 and the inner surface of the installation through hole.

[0062] The first thrust restrictor 6 is arranged between the first thrust plate 7 and the first plane, and the first thrust restrictor 6 is fixedly connected with the first plane. A high-pressure air film is provided between the push plates 7, so that during the rotation of the rotating shaft 2 a...

Embodiment 3

[0066] For the structures in Embodiment 1 and Embodiment 2, the high-pressure air film is used to isolate the surface of the moving pair, which can significantly reduce motion friction, and has the advantages of high precision, high speed, low heat generation, and no pollution.

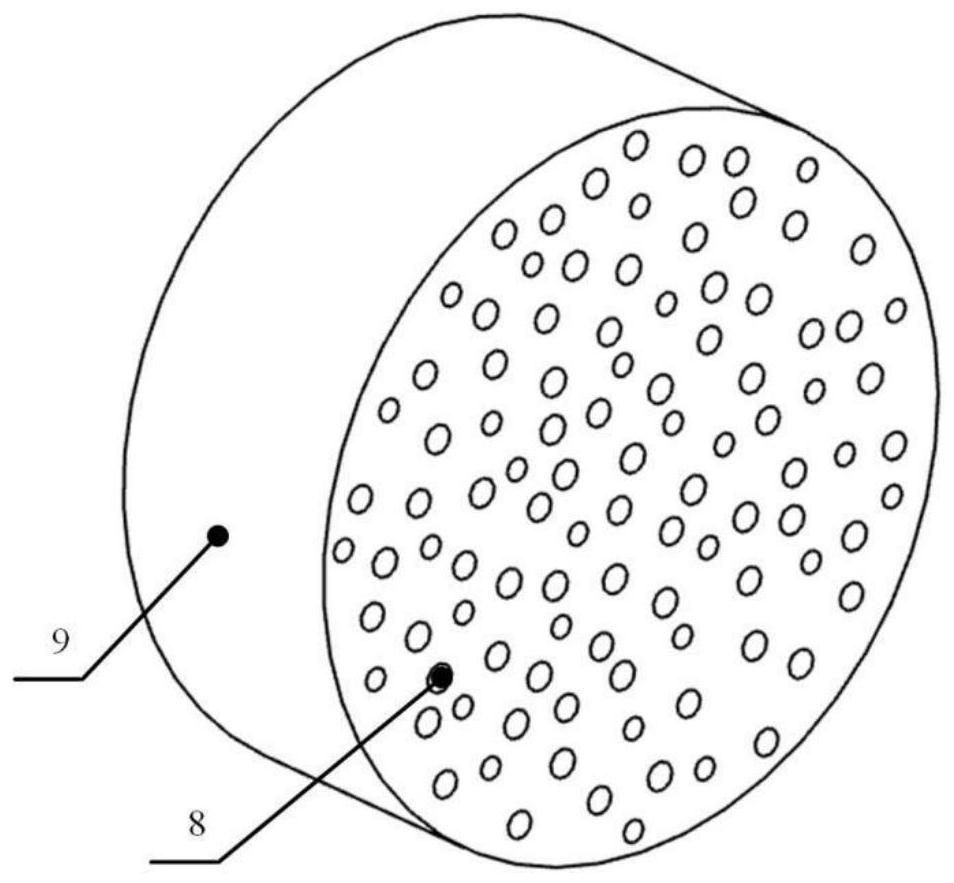

[0067] According to different throttling methods, aerostatic bearings are usually divided into small hole, torus, slit and porous throttling aerostatic bearings, among which small hole throttling and porous throttling aerostatic bearings are more common .

[0068] Porous throttling aerostatic bearings have better bearing capacity, stiffness and stability, but the structure is more complex and inconvenient to process; while small hole throttling air bearings are simple in structure, mature in design, easy to process, and more stable and reliable in performance, but Based on the traditional small hole throttling method, when the gas passes through the pressure equalization chamber structure, there are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com