Device and method for removing particles on surface of electrostatic chuck of etching equipment

An electrostatic chuck and surface particle technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of declining product yield, increasing preventive maintenance, and declining production efficiency, reducing downtime and preventive maintenance. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment relates to a device for removing particles on the surface of an electrostatic chuck of an etching device:

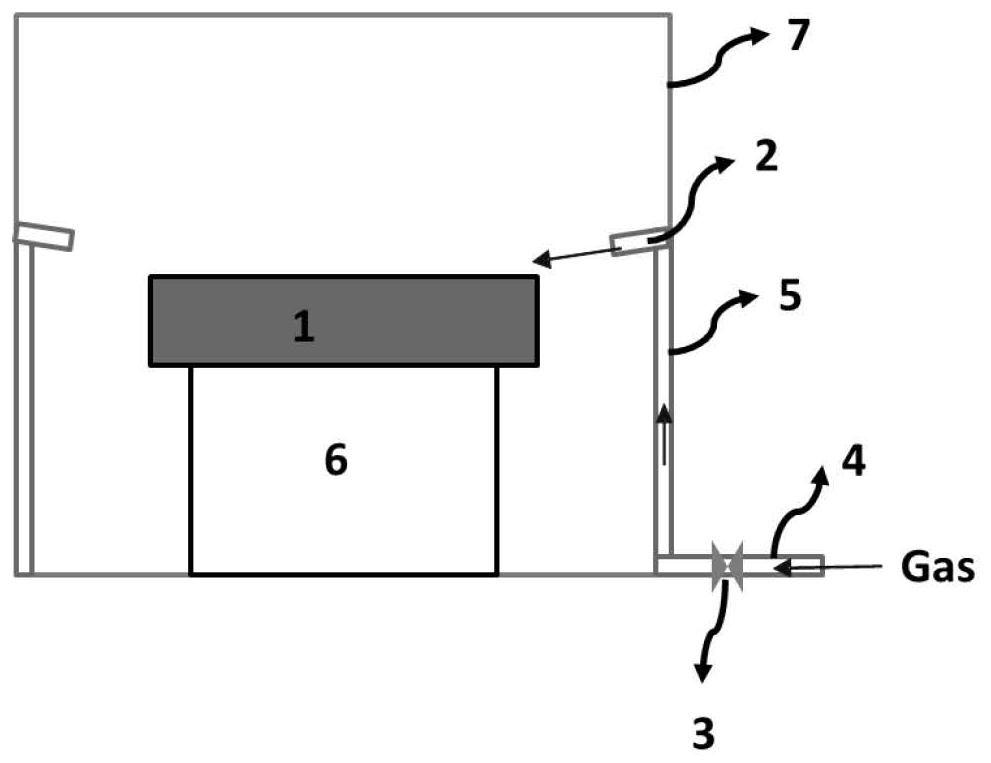

[0051] Such as figure 1 and figure 2 As shown, the device for removing particles on the surface of the electrostatic chuck of the etching equipment includes: a gas supply device, a regulating valve 3 , a main gas supply pipe 4 , a branch gas supply pipe 5 and a nozzle 2 . Wherein the branch gas supply pipe 4 is close to the inner wall 7 of the etching chamber, and connects the main gas supply pipe 5 and the nozzle 2 . The horizontal height of the nozzle 2 is higher than that of the electrostatic chuck 1, the axial height between the nozzle and the upper surface of the electrostatic chuck is 2 cm, and the angle between the nozzle 2 and the horizontal plane is 15 degrees; the regulating valve 3 is composed of a swing valve for starting and Stop purging, and it can also be used to adjust the flow of gas; the gas supply device is a gas cylinder, and...

Embodiment 2

[0057] This embodiment relates to a device for removing particles on the surface of an electrostatic chuck of an etching device:

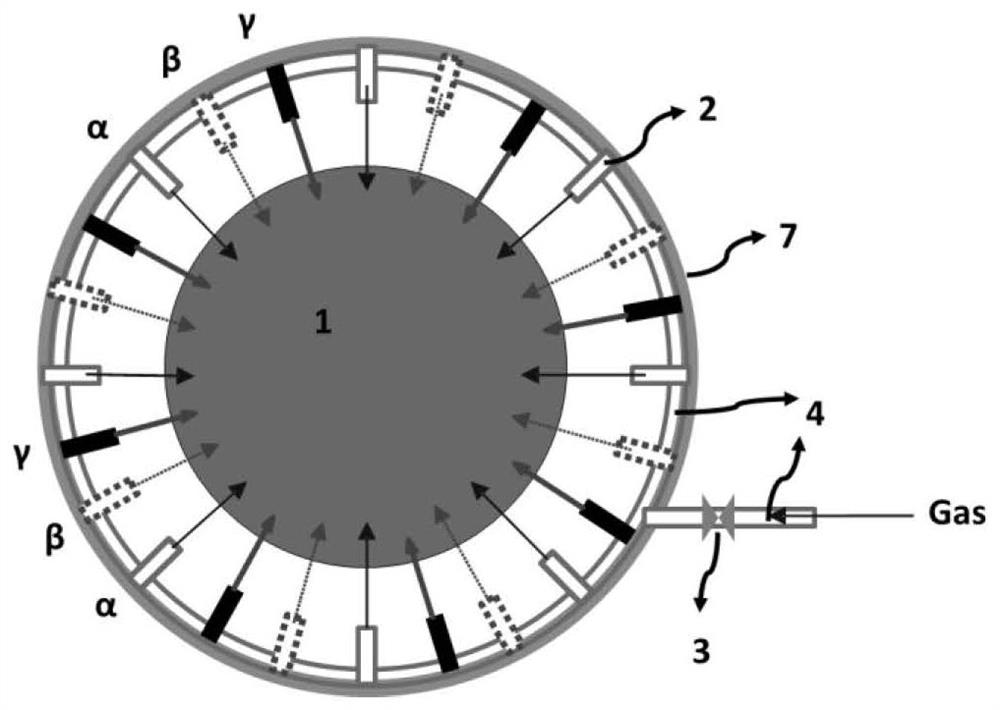

[0058] Such as image 3 As shown, the device for removing particles on the surface of the electrostatic chuck of the etching equipment includes: a gas supply device, a regulating valve 3 , a main gas supply pipe 4 , a branch gas supply pipe 5 and a nozzle 2 . Wherein the branch gas supply pipe 4 is close to the inner wall 7 of the etching chamber, and connects the main gas supply pipe 5 and the nozzle 2 . The horizontal height of the nozzle 2 is slightly higher than that of the electrostatic chuck 1, the axial height between the nozzle and the upper surface of the electrostatic chuck is 3 cm, and the angle between the nozzle 2 and the horizontal plane is 10 degrees; the regulating valve 3 is composed of a butterfly valve for starting and Stop purging, and it can also be used to adjust the flow of gas; the gas supply device is a gas cylinder, and t...

Embodiment 3

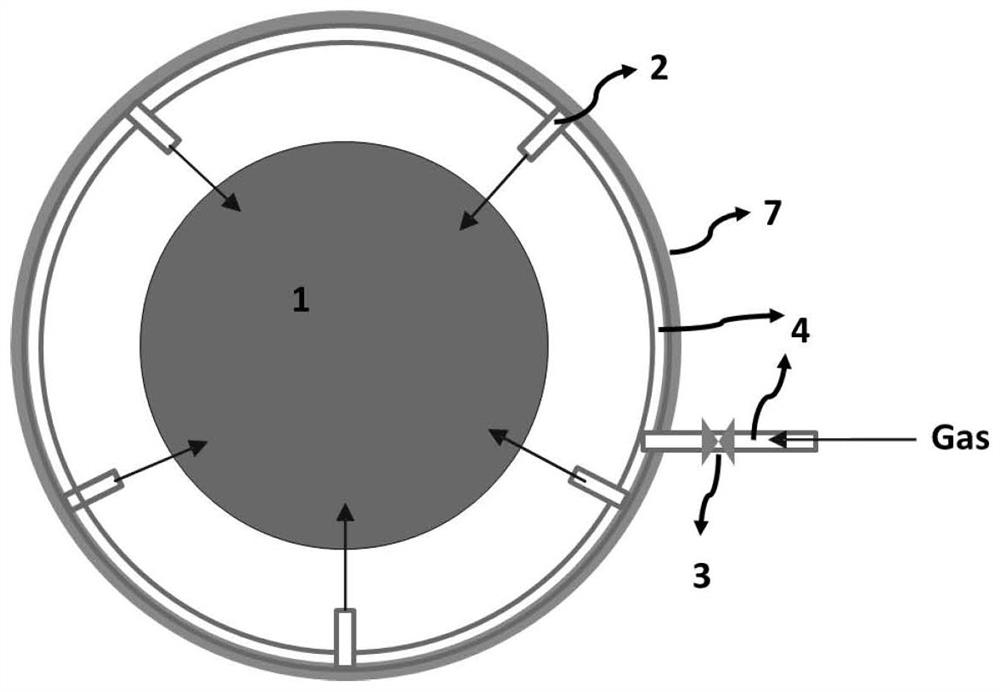

[0064] Such as Figure 4 As shown, the device for removing particles on the surface of the electrostatic chuck of the etching equipment includes: a gas supply device, a regulating valve 3, a main gas supply pipe 4, a branch gas supply pipe 5, a nozzle 2 and a control device. Wherein the branch gas supply pipe 4 is close to the inner wall 7 of the etching chamber, and connects the main gas supply pipe 5 and the nozzle 2 . The horizontal height of the nozzle 2 is slightly higher than that of the electrostatic chuck 1, the axial height between the nozzle and the upper surface of the electrostatic chuck is 5 cm, and the angle between the nozzle 2 and the horizontal plane is 10 degrees; the regulating valve 3 is composed of a butterfly valve for starting and Stop purging, and it can also be used to adjust the flow of gas; the gas supply device is a gas cylinder, and the inert gas nitrogen is stored in the cylinder, and the purity of the high-purity inert gas nitrogen supplied is 5N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com