Safe patient transfer device for intensive care

A transfer device and safe technology, applied in hospital beds, medical science, hospital equipment, etc., can solve the problems of high labor intensity, low reliability, patient injury, etc., and achieve the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

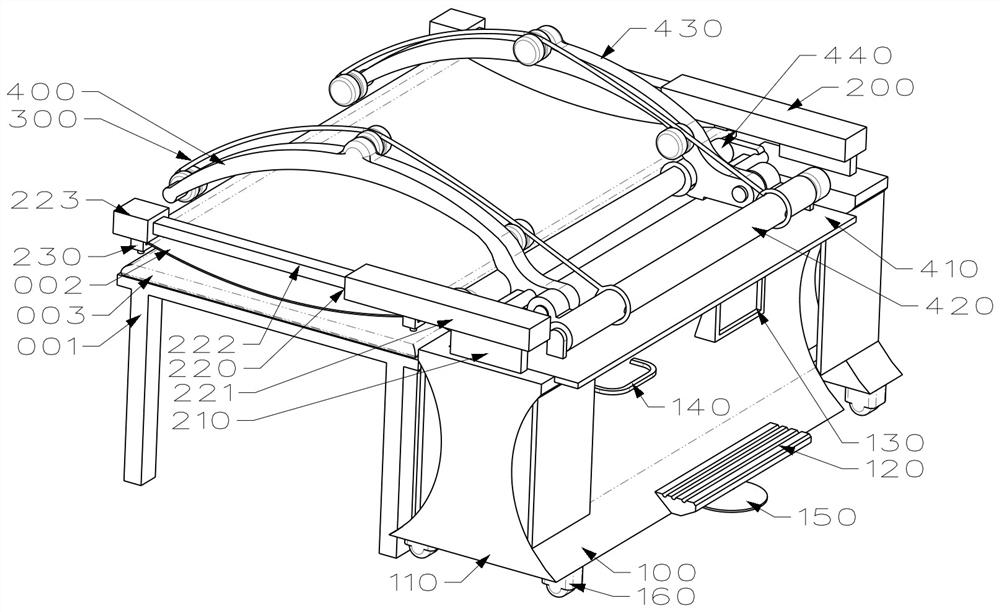

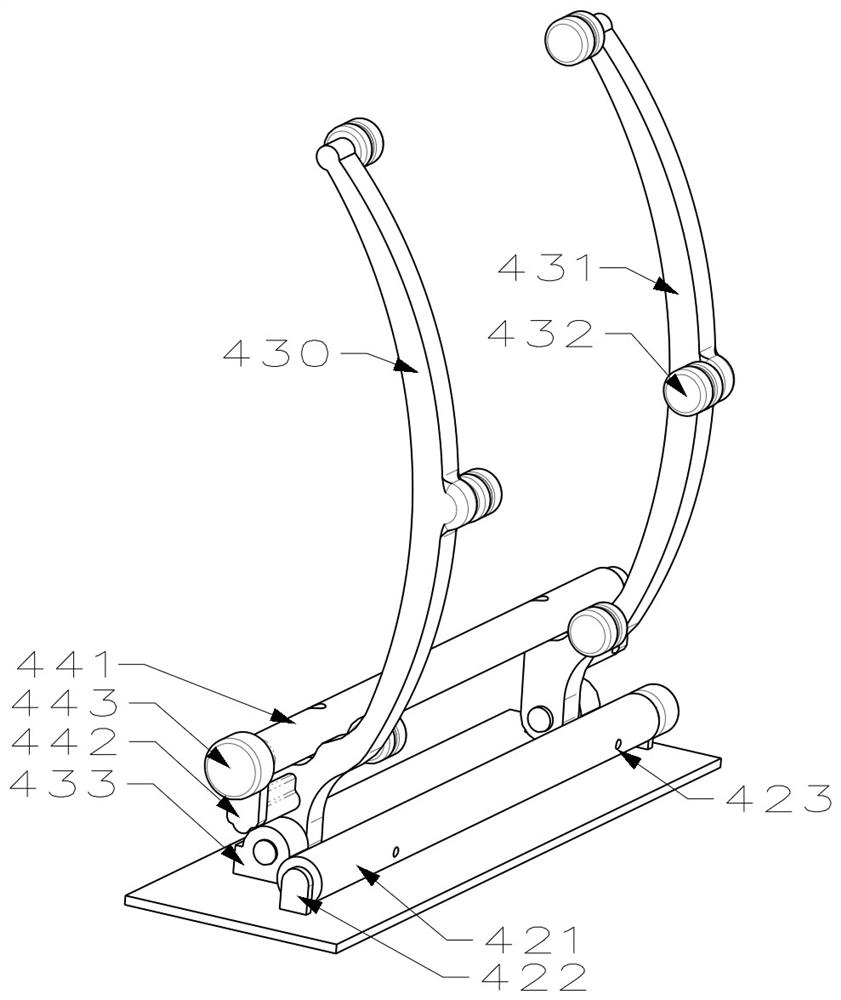

[0066] like figure 1 As shown, the patient safety transfer device for intensive care of the present application includes a travel base 100, a sheet lifting assembly 200, a load-bearing cloth assembly 300, a load-bearing cloth laying assembly 400, a power assembly and a control unit;

[0067] The traveling base 100 plays the role of carrying the sheet lifting assembly 200, the load-bearing cloth assembly 300 and the load-bearing cloth laying assembly 400, and includes the base body 110 and the travel wheel 160; the base body is a frame structure Or box structure; the traveling wheel 160 is positioned at the bottom of the base body 110, and is rotated under the control of the control unit to drive the entire safety transfer device to move;

[0068] Preferably, the traveling wheel 160 can be retracted into the base body 110 .

[0069] Preferably, the base body 110 can be elongated and shortened along its own length direction to adapt to different hospital beds 001 .

[0070] Pr...

Embodiment 2

[0099] Considering that the contact position between the safety transfer device of the present application and the bed needs to be cleaned due to contact with different hospital beds, and the direct removal for cleaning affects the transfer efficiency, if not cleaned in time, it may cause cross-contamination, the embodiment of the present application is based on the above-mentioned embodiment. Certain improvements have been made to the structure of the load-bearing cloth assembly 300, specifically:

[0100] like Figure 13 As shown, the load-bearing cloth assembly 300 includes a load-bearing cloth body 310, a drag rope 320 and a rope head fixing assembly 330; the number of the drag ropes 320 is two, made of nylon or metal, and fixed on the on the main body 310 of the load-bearing cloth; the two drag ropes 320 are parallel to each other, and the distance between them is greater than the radius of the circumscribed circle of the main body of the load-bearing cloth 310; the rope ...

Embodiment 3

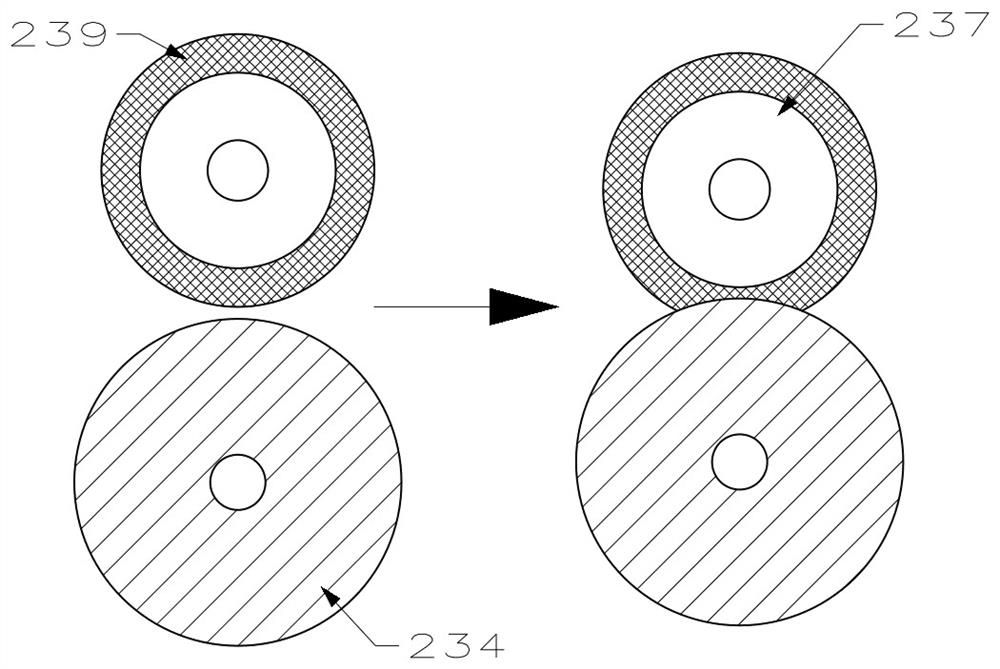

[0109] In the trial production of the safety transfer device of the present application, it was found that the sheet clamping assembly 230 in the prior art has a certain risk of loosening and is likely to cause damage to the sheet 002 during the process of clamping the sheet 002 and lifting the sheet 002; In view of the above problems, the embodiment of the present application optimizes the structure of the sheet clamping assembly 230 on the basis of the above-mentioned embodiments, improves the stability of clamping the sheet 002 and reduces the damage to the sheet 002; specifically:

[0110] like Figure 8 and Figure 9 As shown, the sheet clamping assembly 230 includes a bearing assembly 231, a rotating drum 234, a sheet corner guide plate 235, a rotating drum supporting assembly 236, a pressing roller 237 and a pressing roller positioning assembly 238; the bearing assembly 231 It is a rod-shaped or block-shaped structure, positioned on the sliding telescopic rod 220, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap