A polishing machine for the finishing of aircraft flap slide rails

A technology for an aircraft and a polishing machine is applied in the field of polishing machines for the finishing of aircraft flap slide rails, which can solve the problems of poor polishing effect, poor finish, and insufficient flatness of the flap slide rails, so as to ensure the flatness and facilitate rapid shedding. , Improve the effect of polishing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

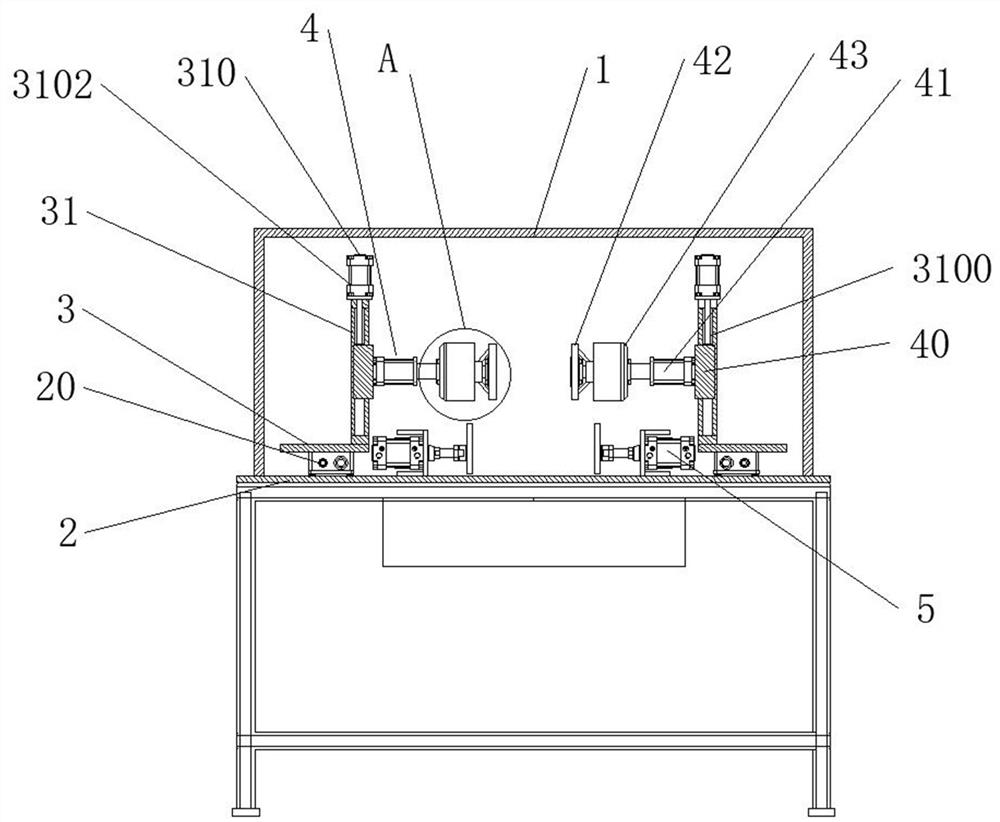

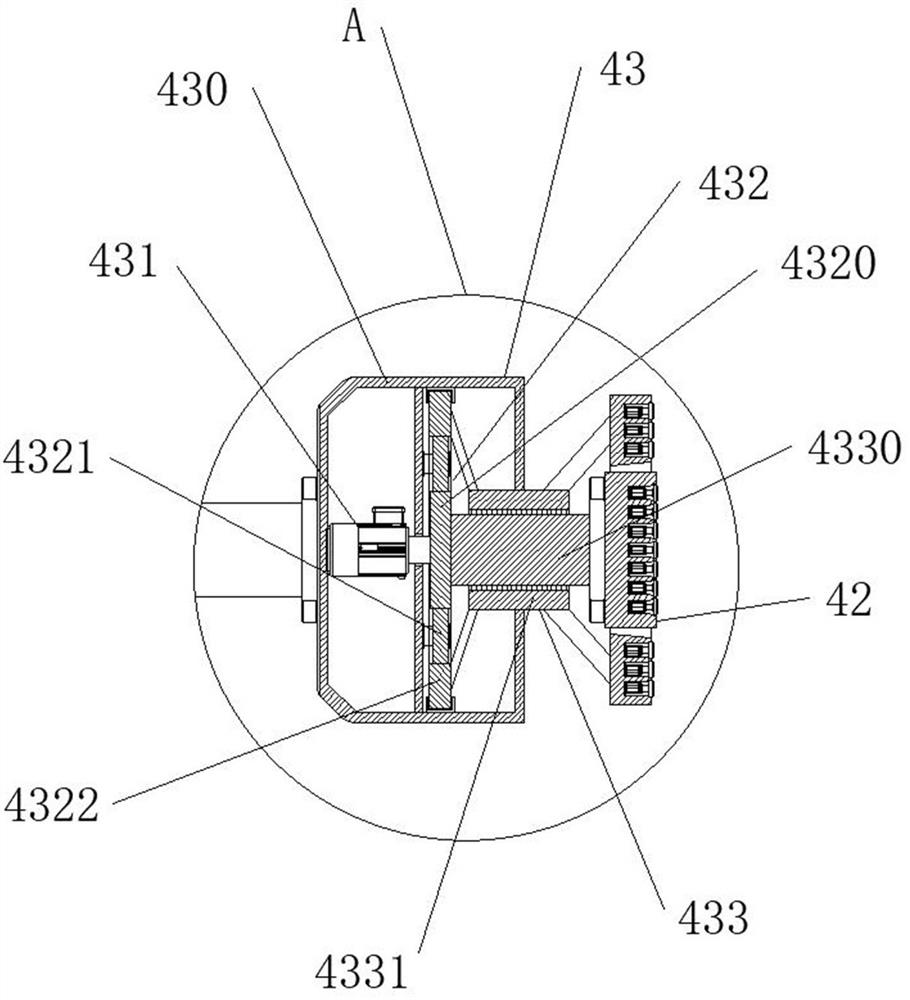

[0035] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 8 As shown, the present embodiment provides a polishing machine for finishing an aircraft flap slide rail, comprising a casing 1, a workbench 2 is arranged inside the casing 1, and a frame 3 is symmetrically arranged on both sides of the top of the workbench 2, The opposite inner sides of the two racks 3 are provided with a polishing mechanism 4; any polishing mechanism 4 includes a side plate 40, an electric push rod 41 and a polishing assembly, and the side plate 40 away from the rack 3 passes through the electric push rod 41. Connected with the polishing assembly; the polishing assembly includes a polishing disc 42 and a power assembly 43 for driving the polishing disc 42 to rotate, one side of the power assembly 43 is connected to the output end of the electric push rod 41, and the power assembly 43 is far away from the electric One side of the push rod 41 is connected with the...

Embodiment 2

[0045] like Figure 7 As shown in the figure, a polishing machine for the finishing of aircraft flap slide rails further includes a polishing mechanism 422 staggered on the polishing surfaces of the first polishing sub-disk 420 and the second polishing sub-disk 421. The polishing mechanism 422 includes one end that is opposite to the polishing surface. Connected empty groove 4220, hydraulic push rod 4221 and grinding piece 4222, one end of the empty groove 4220 communicating with the polishing surface is provided with a placing groove, the grinding piece 4222 is embedded in the placing groove, and one side protrudes outside the flared part, The hydraulic push rod 4221 is coaxially arranged in the cavity 4220, and the output end is connected with the grinding piece 4222 through the piston rod, so that when the polishing machine polishes the slide rail, the hydraulic push rod 4221 can push the grinding piece 4222 to be close to the grinding piece 4222. On the to-be-polished surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com