Lightweight heavy-load wheel set and design method thereof

A light-weight, wheel-set technology, applied in the direction of wheel, axle combination, rolling resistance optimization, etc., can solve the problems of increasing the unsprung weight of the vehicle bogie, affecting the mechanical performance and transportation efficiency of the vehicle, and achieve a balance between performance and practical economy , improved dynamic performance, and easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following is a description of the embodiments, the specific embodiments of the present invention are described in further detail.

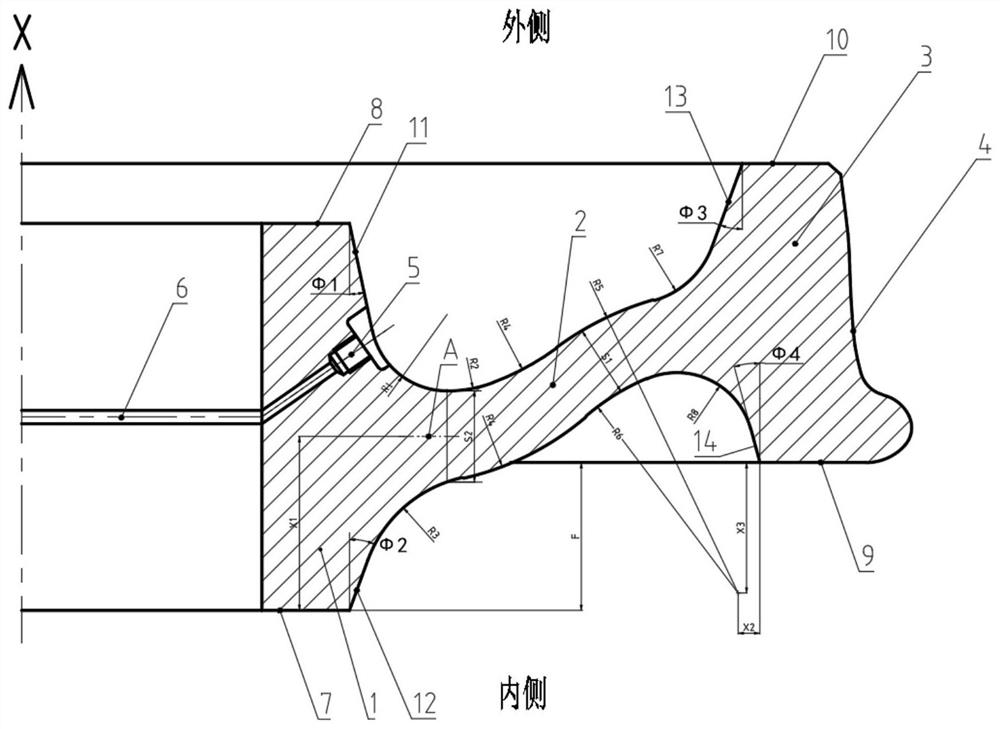

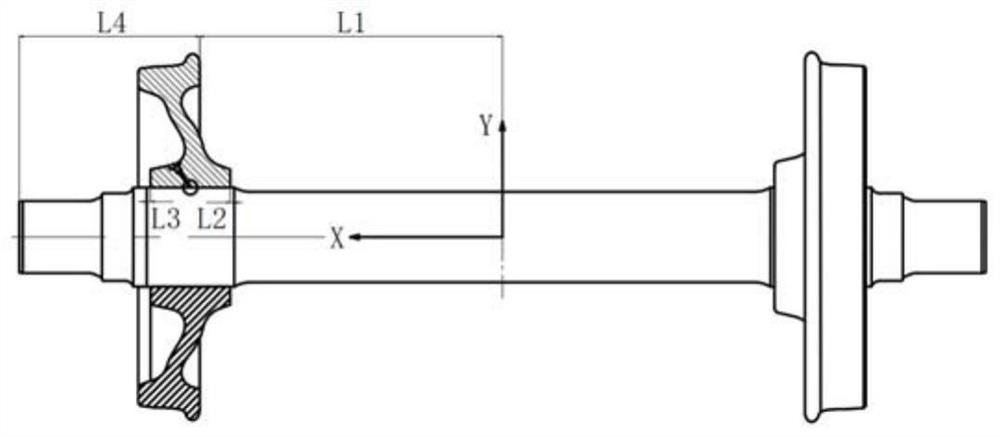

[0059] as Figures 1 through 8 As shown, the overall wheels of the railway wagon, including hub 1, spoke plate 2, spoke 3 and tread 4, spoke 2 is a curved structure, one end of spoke plate 2 is connected to hub 1, the other end of spoke plate 2 is connected to rim 3, and the rim 3 is provided with rim 14 and pedal 4 at one end away from spoke plate 2.

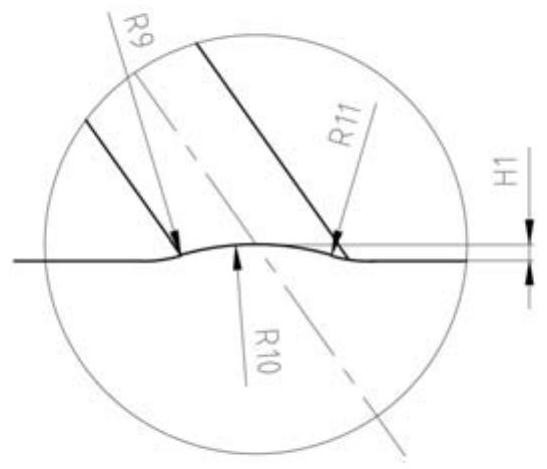

[0060] Axially upwards, the spoke-spoke transition zone is located on the outside of the hub-spoke transition zone. The angle between the outer contour line of the hub 1 outer diameter surface hub 11 and the outer hub surface of the wheel hub 8 is Φ1, Φ1≥98 °. The angle between the inner contour line of the hub 1 outer diameter surface of the hub 12 and the inner hub surface of the wheel hub 7 is Φ2, Φ2≥100 °. The angle between the rim inner diameter surface rim outer contour line 13 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com