Electric power safety fence stacking trolley

An electric safety and fence technology, applied in the field of stacking trolleys, can solve the problems of high center of gravity of the fence, potential safety hazards, and the fall of the fence, and achieve the effect of increasing the carrying capacity, improving the work efficiency, and being convenient to put in.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

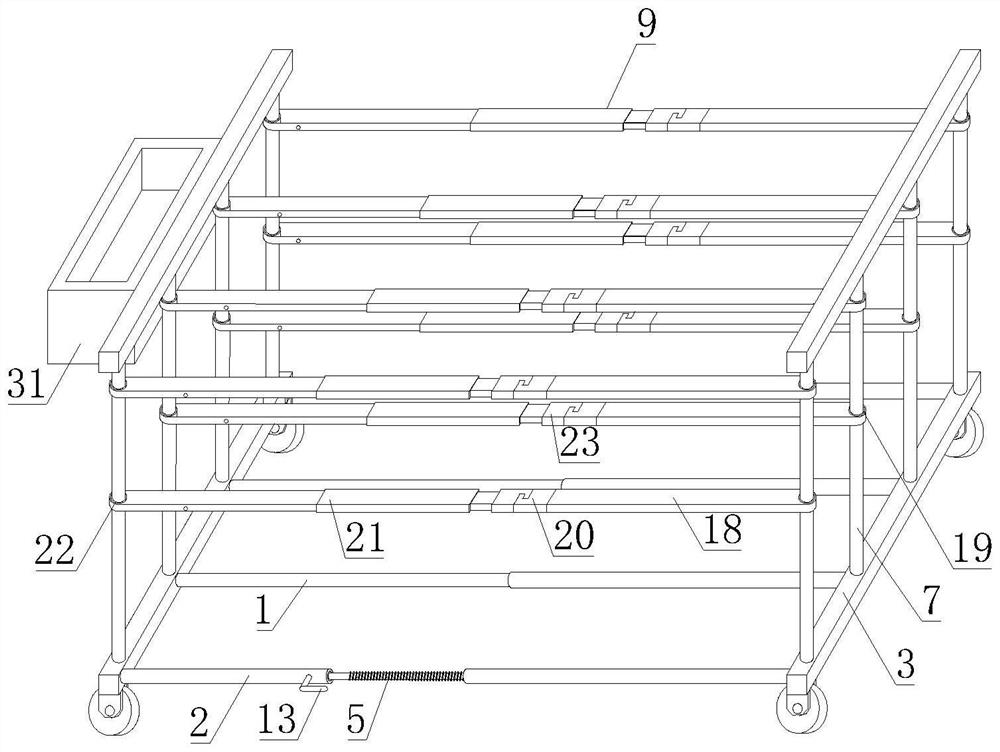

[0025] Example 1. An electric safety fence stacking trolley is composed of Figure 1-4 As shown, it includes a bottom support frame, and the bottom support frame includes a telescopic rod 1 and an adjustment rod 2 that are parallel to each other. 2 includes an adjustment section 4, the adjustment section 4 is connected to the movement section 6 through the screw rod 5, the upper end of the connecting rod 3 is evenly provided with a plurality of vertical support rods 7, and the upper end of the vertical support rod 7 is provided with a top limit corresponding to the bottom support frame The vertical support rod 7 is provided with a split limit rod group 9.

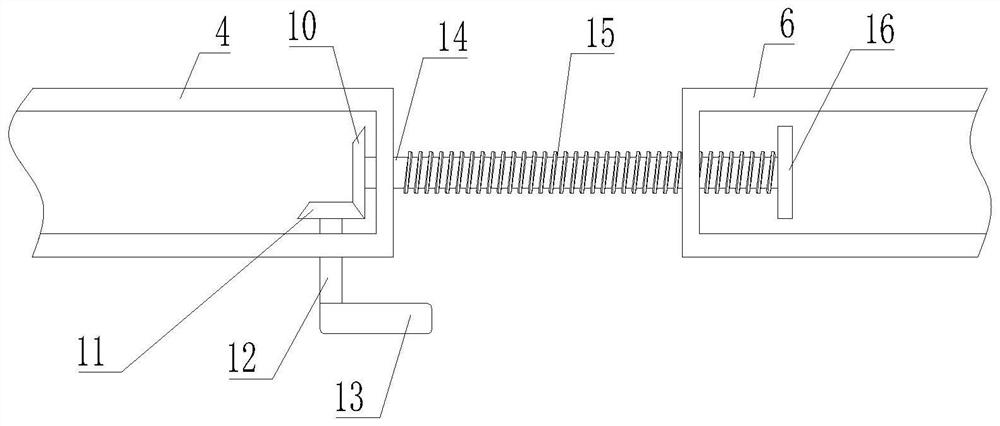

[0026] The screw rod 5 includes a smooth section 14 connected with the adjustment section 4 and a threaded section 15 connected with the moving section 6 .

[0027] The adjusting section 4 is connected to the smooth section 14 of the screw rod 5 through a bearing. The adjusting section 4 is provided with a first bevel gea...

Embodiment 2

[0035] In Embodiment 2, on the basis of Embodiment 1, a screw seat is set in the movement section 6 instead of directly setting a thread in the movement section 6, so that it is convenient to replace when damage occurs, and the replacement is convenient.

Embodiment 3

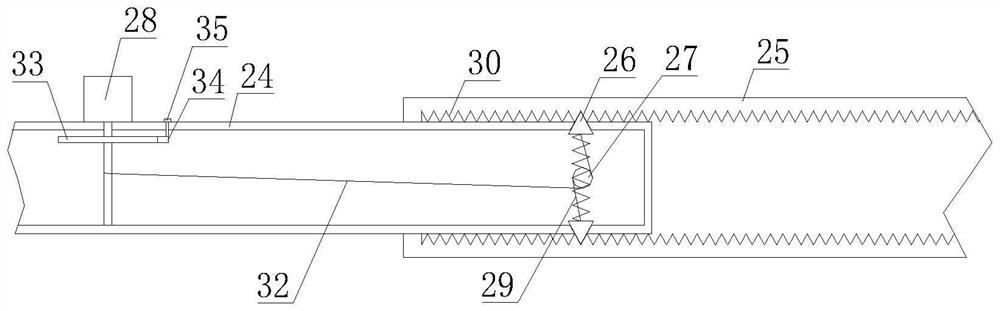

[0036] Embodiment 3, on the basis of Embodiment 1, a ratchet wheel is provided on the knob 28. When the knob 28 is rotated to shrink the lock catch 26, the pawl 34 can hold the knob 28, so that the lock catch 26 cannot be under the action of the spring. Reply directly to avoid the need for the staff to always hold the knob 28 with one hand, so that the staff can better adjust the length of the second limit rod 21. After the adjustment, by turning the lever 35, the ratchet 33 will be between the locks 26. The inner rod 24 and the outer rod 25 are fixed by rotating under the action of the spring.

[0037]The working principle of the present invention: the length of the trolley is adjusted by the number of electric safety fences to be loaded. The length of the trolley can be realized by rotating the rocker 13. When the rocker 13 rotates, it will drive the second bevel gear 11 to rotate, and the second bevel gear 11. Meshing the first bevel gear 10 makes the first bevel gear 11 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com