A kind of high-entropy rare earth co-doped nanometer low heat transfer powder material and preparation method thereof

A powder material and co-doping technology, which is applied in nanotechnology, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of short and narrow near-infrared absorption wavelengths, and achieve controllable particle size and crystal grain size. Uniform distribution and single phase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

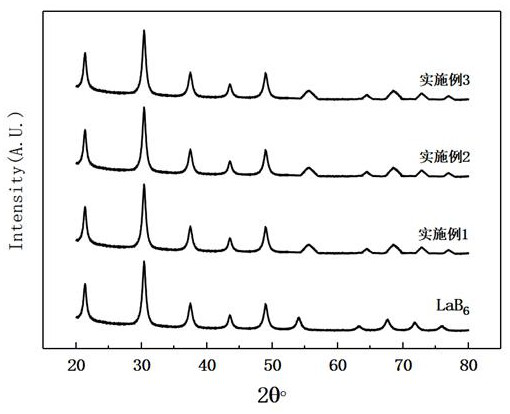

Embodiment 1

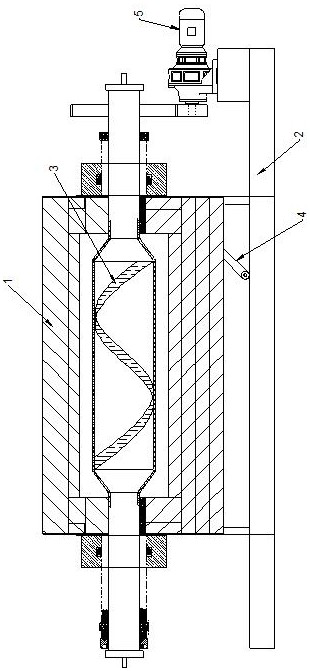

[0052] A preparation method of high-entropy rare earth co-doped nanometer low heat transfer powder material, comprising the following steps:

[0053] (1) Set Y 2 (CO 3 ) 3 358g, La 2 (CO 3 ) 3 1373g, EuCl 3 258g, Ce 2 (CO 3 ) 3 460g, Sm 2 (CO 3 ) 3 487g, B 2 O 3 2089g, Na 552g and SiO 2 720g (Y:La:Eu:Ce:Sm:B:Na:SiO 2 The molar ratio was 0.1:0.6:0.1:0.1:0.1:6:24:12) into the autoclave, 15 moles of hydrogen was poured in, the temperature was raised to 320°C and fully stirred for 2 hours, and the obtained product was extracted and fractionated. layer, the precipitation was washed 5 times with suction filtration, dried at 110 °C for 5 hours, then dropped into a sand mill together with 6kg of deionized water to grind a 506-nanometer slurry for 12 hours, and the slurry was sprayed and granulated to obtain a 754-nanometer slurry. The spherical powder is finely granulated by using a high-energy jet mill to obtain an R1 of 246 nm. x R2 y R3 z R4 w R5 n B 6 Pre...

Embodiment 2

[0058] A preparation method of high-entropy rare earth co-doped nanometer low heat transfer powder material, comprising the following steps:

[0059] (1) Ce (NO 3 ) 3 326g, La 2 (CO 3 ) 3 1373g, EuCl 3 258g, NdCl 3 256g, Sm 2 (CO 3 ) 3 487g, B 2 O 3 2089g, Na 552g, SiO 2 720g (Ce:La:Eu:Nd:Sm:B:Na:SiO 2 The molar ratio was 0.1:0.6:0.1:0.1:0.1:6:24:12) into the autoclave, 15 moles of hydrogen was poured in, the temperature was raised to 320°C and fully stirred for 2 hours, and the obtained product was extracted and fractionated. layer, the precipitation was washed with suction filtration water 5 times, dried at 110 ° C for 5 hours, then dropped into a sand mill and ground for 12 hours with 6kg deionized water, the obtained 508-nanometer slurry was sprayed and granulated, and the obtained 781 The nano-sized spherical powder is subjected to secondary grinding with a high-energy jet mill, and the obtained 152-nanometer R1 x R2 y R3 z R4 w R5 n B 6 The precu...

Embodiment 3

[0064] A preparation method of high-entropy rare earth co-doped nanometer low heat transfer powder material, comprising the following steps:

[0065] (1) The EuCl 3 258g, La 2 (CO 3 ) 3 1373g, Sm 2 (CO 3 ) 3 487g, GdCl 3 264g, Ce(NO 3 ) 3 326g, B 2 O 3 2089g, Na 552g, SiO 2 720g (Eu:La:Sm:Gd:Ce:B:Na:SiO 2 The molar ratio was 0.1:0.6:0.1:0.1:0.1:6:24:12) into the autoclave, 15 moles of hydrogen was poured in, the temperature was raised to 320°C and fully stirred for 2 hours, and the obtained product was extracted and fractionated. layer, the precipitation was washed with suction filtration water 5 times, dried at 110 ° C for 5 hours, then dropped into a sand mill together with 6kg of deionized water and ground for 12 hours, the obtained 594-nanometer slurry was sprayed and granulated, and the obtained The spherical powder of 782 nanometers is ground using an air mill, and the obtained R1 of 166 nanometers is x R2 y R3 z R4 w R5 n B 6 The precursor, the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com