Bran discharging mechanism and milling equipment

A kind of grinding equipment and grinding technology, which is used in agricultural machinery and equipment, separating solids from solids by air flow, and shelling of grains, etc. Problems such as incomplete chaff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described below with reference to the accompanying drawings and embodiments.

[0025]

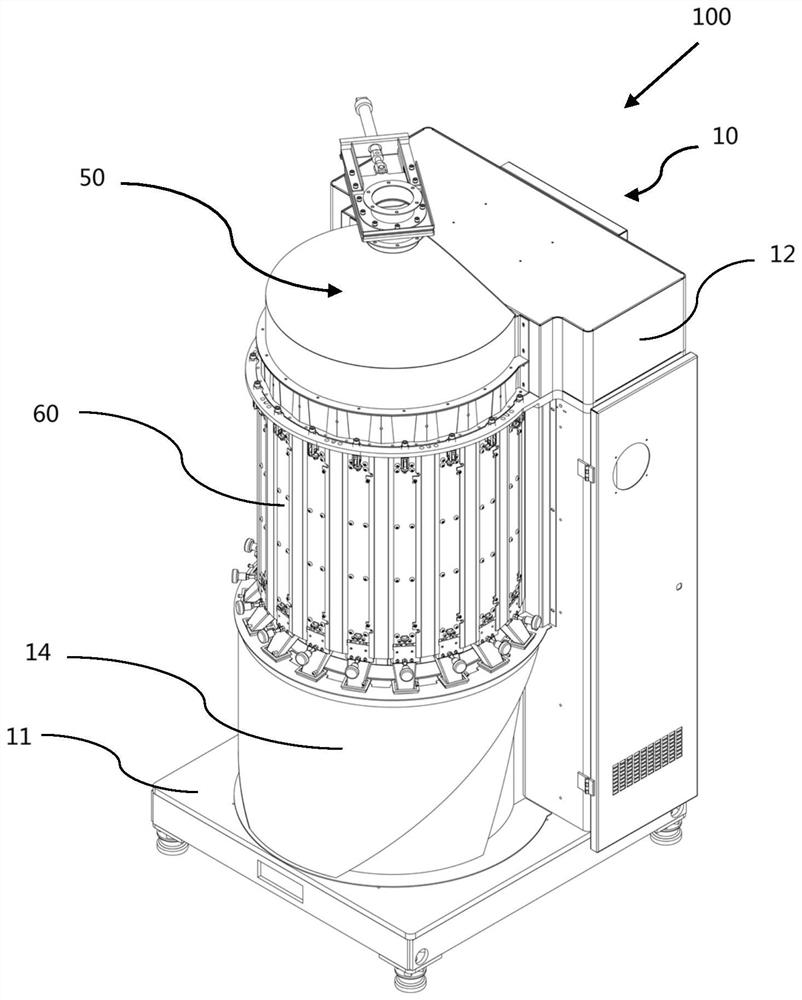

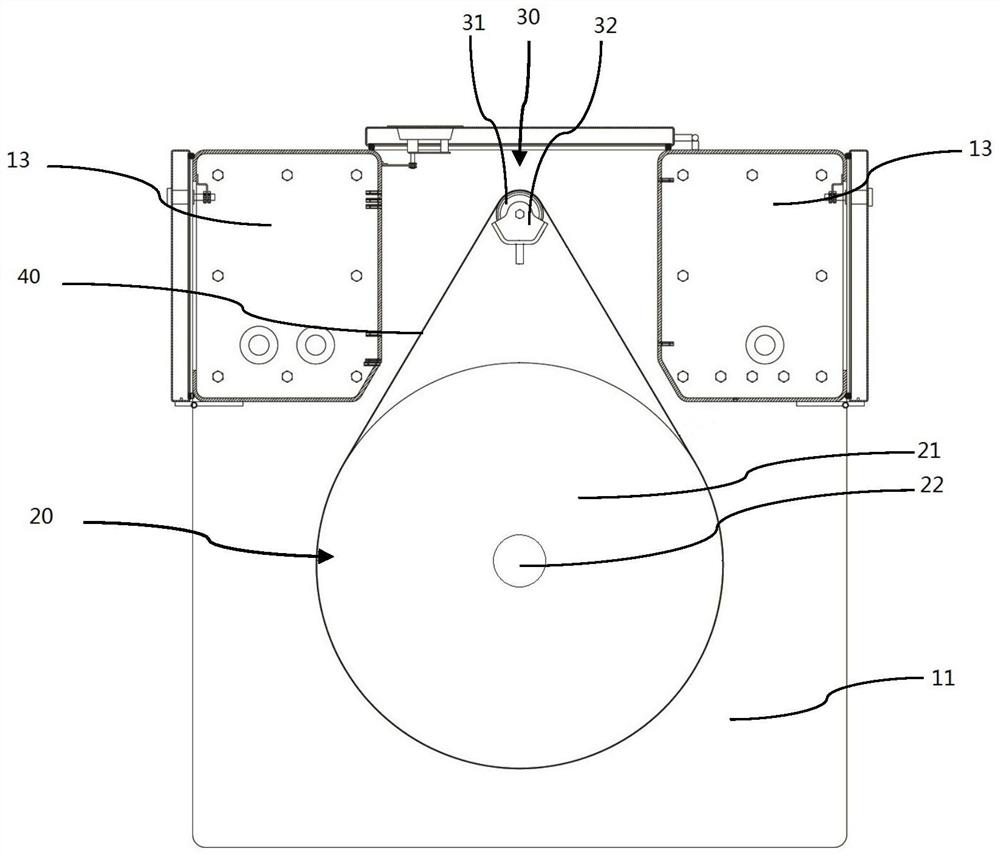

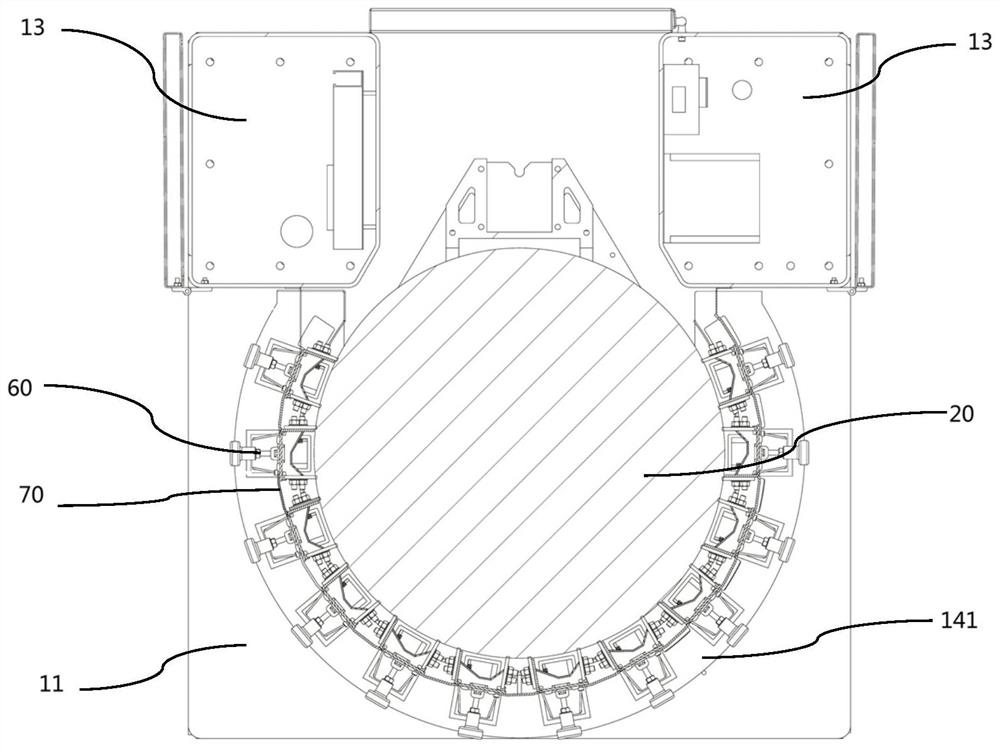

[0026] figure 1 It is a schematic diagram of the structure of the grinding equipment in the embodiment of the present invention. figure 2 It is a schematic diagram of the structure of the main drum, the tension drum and the abrasive belt in the embodiment of the present invention.

[0027] like figure 1 and figure 2 As shown, the present embodiment provides a milling apparatus 100 for milling grains, including a frame 10, a main drum 20, a tension drum 30, an abrasive belt 40, a feeding mechanism 50, a whitening chamber 60, and The bran discharging mechanism 70 . In this embodiment, the milled grain is brown rice, and the milling equipment has 100 rice mills, which are used for grinding brown rice to form polished rice. The grinding of brown rice is taken as an example for detailed description.

[0028] The rack 10 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com