Roll changing and rolling buffer device of middle-high voltage corrosion foil production line

A medium and high pressure corroded foil and buffer device technology, which is applied in the field of corroded foil production line, can solve the problems of untensioned foil, affecting the normal winding operation of foil, damage and other problems, so as to prevent mispressing, improve the flexibility of use and Convenience, good limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

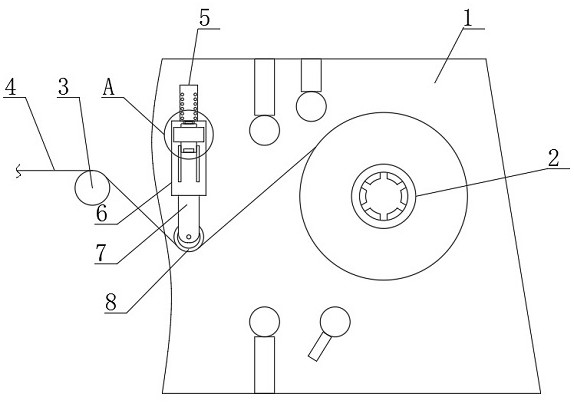

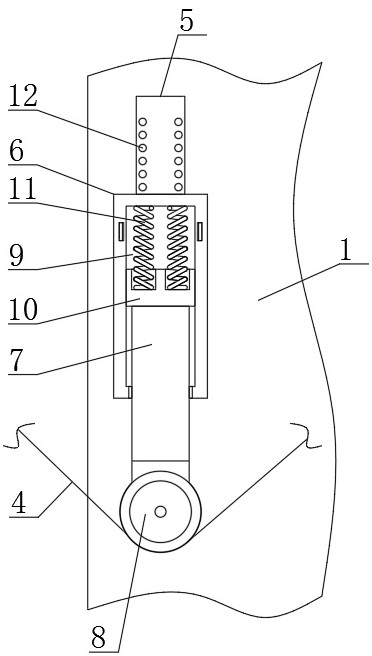

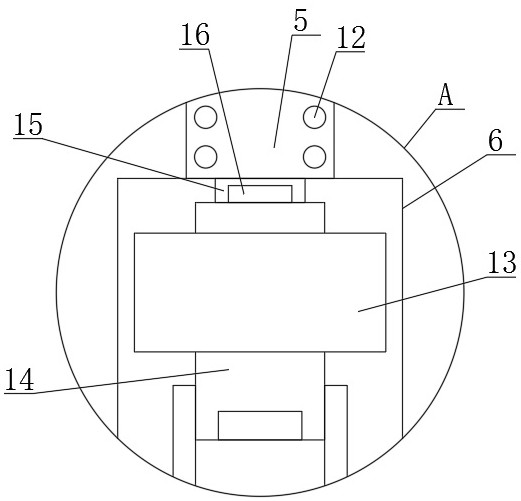

[0025] see Figure 1 to Figure 5 , the present invention provides a technical solution: a buffer device for rewinding and rewinding of a medium and high pressure etched foil production line, comprising a substrate 1, a rewinding roller 2, a first drive roller 3, a foil 4 and a buffer device, and the rewinding roller 2 rotates to install Set on the base plate 1, the first drive roller 3 is located on one side of the base plate 1, the winding roller 2 is wound with a foil 4, and the buffer device includes an I-shaped base rail 5, a base block 6, a telescopic block 7 and a buffer guide roller 8 , the base block 6 is movably sleeved on the surface of the I-shaped base rail 5, and there is an adjustment structure between the base block 6 and the I-shaped base rail 5, and a telescopic groove 9 is opened inside the base block 6, and the interior of the telescopic groove 9 is movable An inner slider 10 is provided, the telescopic block 7 is fixed on the bottom surface of the inner sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com