Numerical control machine tool

A technology of CNC machine tools and bed bodies, which is applied in the field of machine tools and can solve problems such as workpiece clamping troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The following is combined with the attached Figure 1-4 Further elaboration of this application.

[0035] Embodiments of the present application disclose a CNC machine tool.

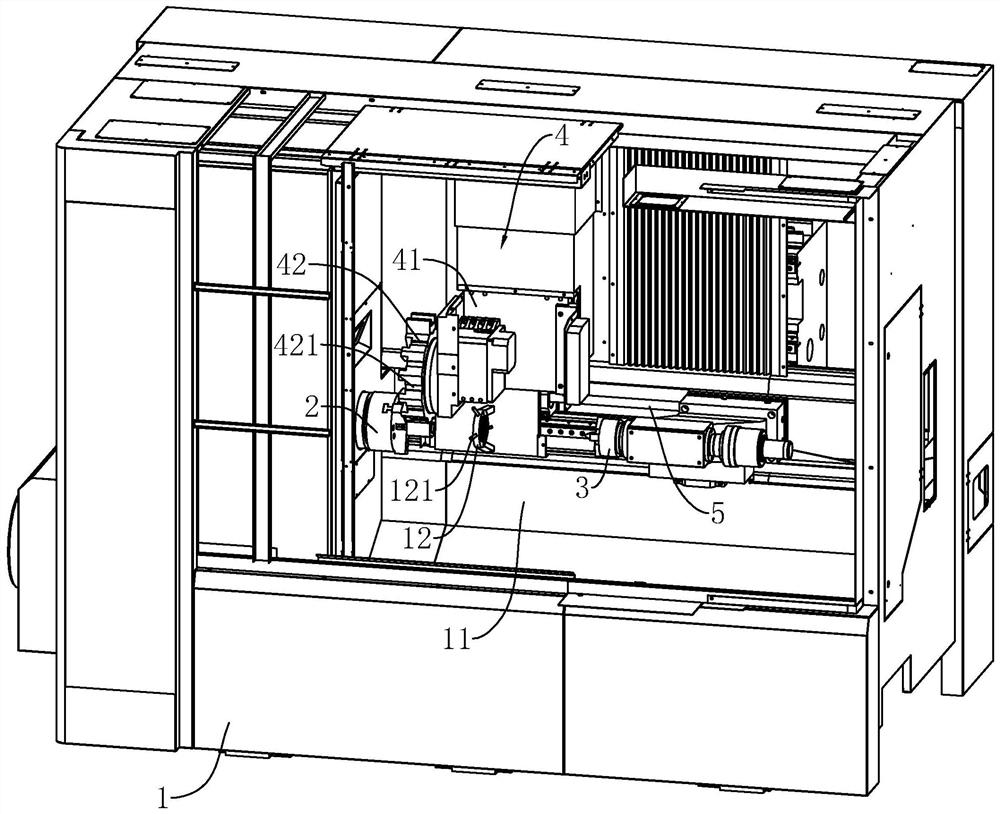

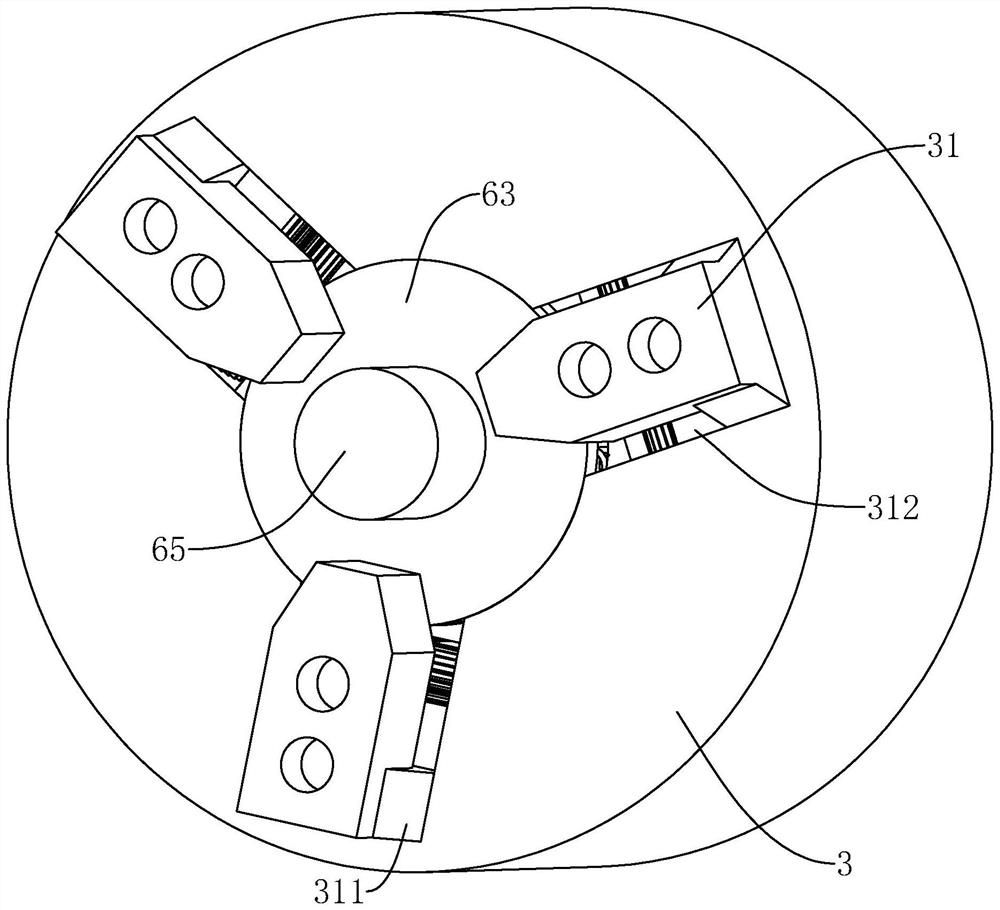

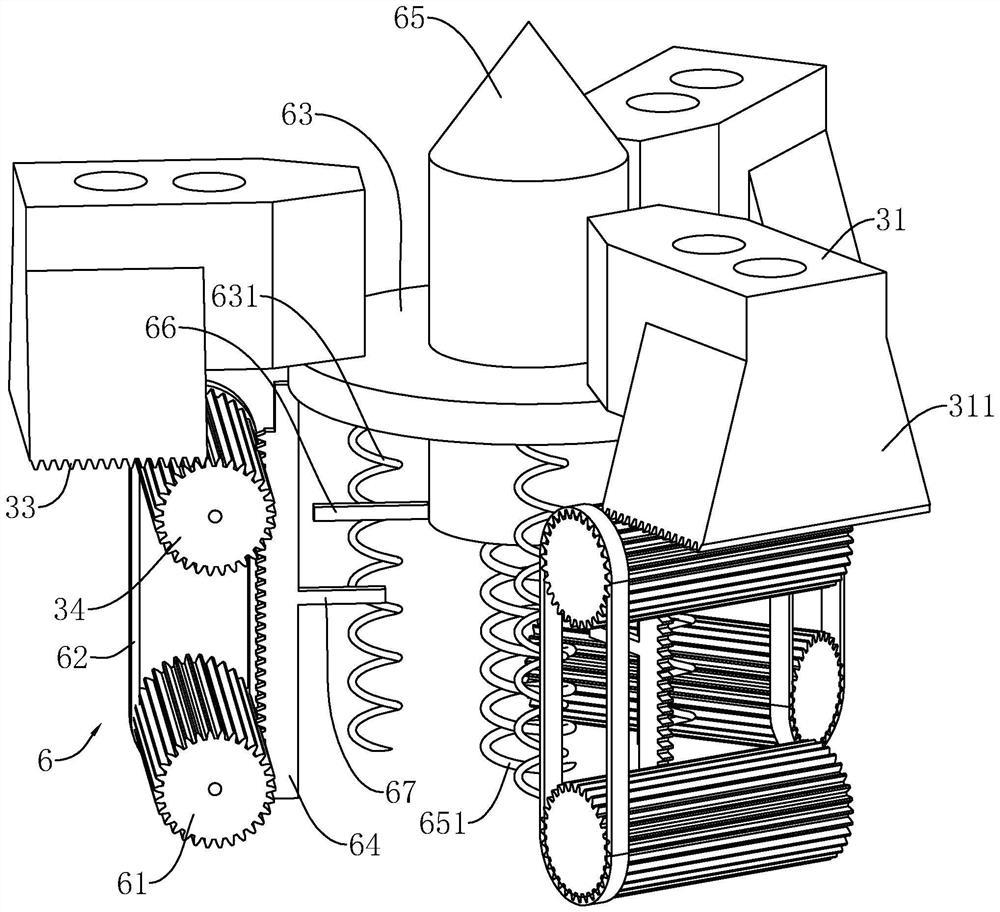

[0036] Reference Figure 1 , CNC machine tools include bed 1, main chuck 2, sub-chuck 3, cutting mechanism 4, push component 5, bed 1 is opened to accommodate the main chuck 2, sub chuck 3, cutting mechanism 4, push component 5 processing chamber 11. The main chuck 2 rotation is mounted on the bed 1, the sub-chuck 3 slips in the processing chamber 11 and the main chuck 2 corresponds, i.e., the sub-chuck 3 slides along the main chuck 2 rotation axis extension direction, while the sub-chuck 3 also rotates in the bed 1. Push assembly 5 is located at the bottom of the bed 1 to push the sub-chuck 3 to slide, the cutting mechanism 4 is located between the main chuck 2, the sub-chuck 3.

[0037] Reference Figure 1 , the cutting mechanism 4 includes a slider 41 that slides on the bed 1, a tool holder 42 that rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com