Cutter life dynamic prediction method

A technology for tool life and dynamic prediction, applied in manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of incomplete tool life prediction model and difficulty in accurately predicting tool life, etc., to improve accuracy and rationality , The effect of reducing processing costs and cutting tool waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

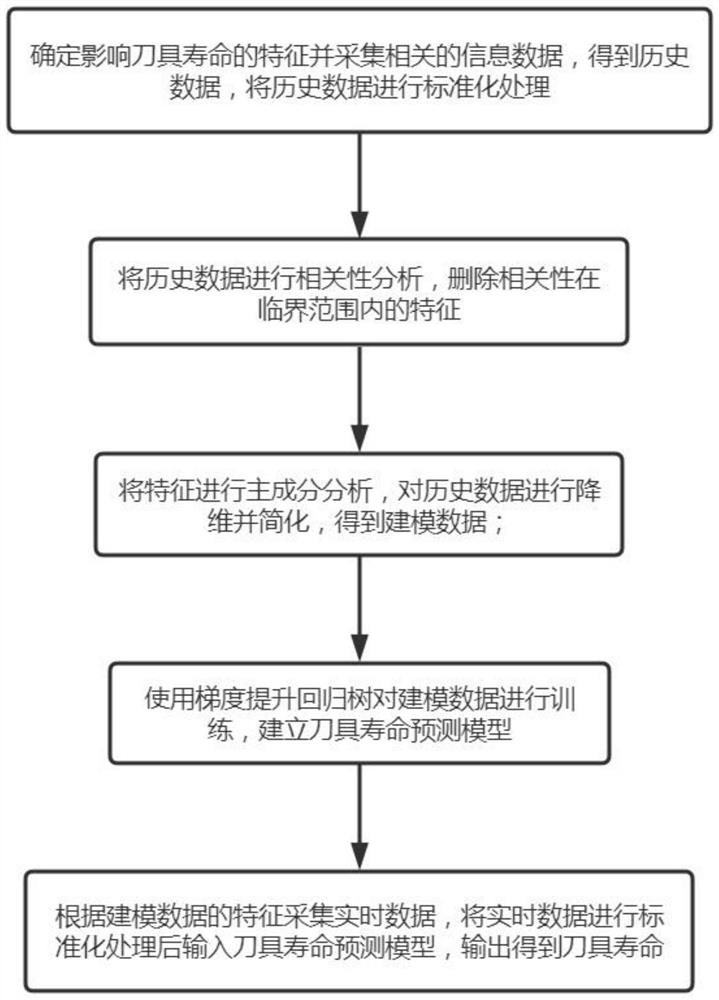

[0072] like image 3 As shown, a tool life dynamic prediction method of the present invention includes the following steps:

[0073] S1: Determine the features that affect the tool life and collect relevant information data, obtain historical data, and standardize the historical data;

[0074] S2: Perform correlation analysis on historical data, and delete features whose correlation is within the critical range;

[0075] S3: Perform principal component analysis on the features, reduce and simplify the historical data to obtain modeling data;

[0076] S4: Use the gradient boosting regression tree to train the modeling data to establish a tool life prediction model;

[0077] S5: Collect real-time data according to the characteristics of the modeling data, standardize the real-time data and input it into the tool life prediction model, and output the tool life.

[0078] In this embodiment, the life prediction is performed on the tool used for machining the aviation structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com