A flexible packaging bag conveying device

A conveying device and flexible packaging bag technology, applied in the field of flexible packaging bag conveying devices, can solve the problems that the operating mechanism of electrical equipment is difficult to operate according to the design requirements, it is difficult to ensure the efficient transmission of packaging bags, the difficulty of loading materials, and the difficulty of increasing maintenance, etc., so as to achieve convenient maintenance And the effects of maintenance, stable operation, and avoidance of production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

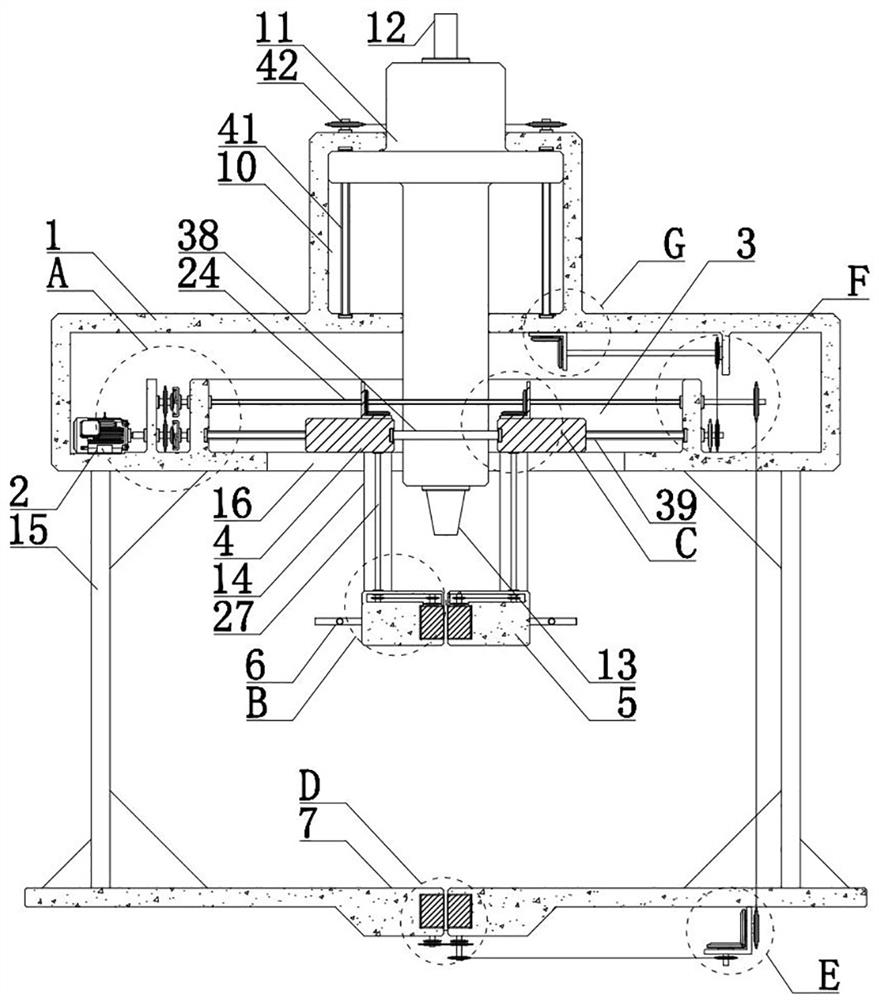

[0030] see figure 1 , a flexible packaging bag conveying device, comprising an installation box 1, a conveying mechanism, a bag opening mechanism, a bag filling mechanism, and a driving motor 2, and the driving motor 2 is fixedly installed in the installation box 1 and is connected with the conveying mechanism, the bag opening mechanism, and the bag filling mechanism. linked;

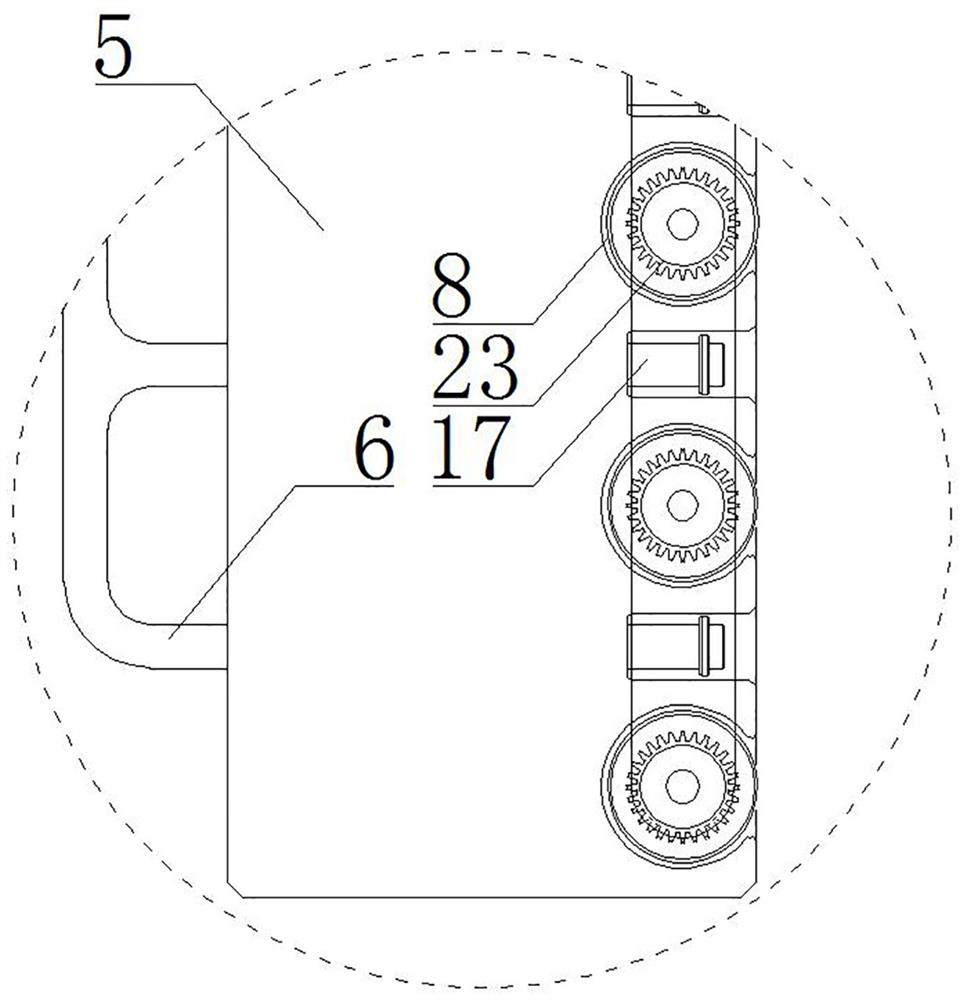

[0031] The bag opening mechanism includes: a first chute 3 opened in the installation box 1 and arranged in the horizontal direction, two sets of sliding seats 4 that are slidably installed in the first chute 3 and maintain symmetrical movement, and are fixedly installed at the bottom of the sliding seat 4 The installation seat 5 is arranged on the lower side of the installation box 1, and the air extraction pipeline 6 is arranged in the installation seat 5; the two sets of sliding seats 4 are driven by the driving motor 2 to move relative or opposite to each other along the first chute 3 to The two se...

Embodiment 2

[0035] see figure 1 , 9 , 10, and the present invention is further supplemented and explained in conjunction with Embodiment 1, the sliding seat 4 is fixedly connected with the mounting seat 5 on the corresponding side through the vertically arranged first connecting column 14 to ensure that the mounting seat 5 can be stable with the sliding seat 4 The installation box 1 is fixedly connected to the installation bottom plate 7 on the corresponding side through the vertically arranged second connecting column 15 to ensure that the installation bottom plate 7 can be stably connected to the installation box 1; the bottom wall of the installation box 1 is provided with an installation hole 16, and the first A connecting column 14 and the feeding seat 11 are arranged through the installation through hole 16 to avoid spatial interference between the first connecting column 14 , the feeding seat 11 and the installation box 1 .

[0036] The air extraction pipeline 6 is connected to a ...

Embodiment 3

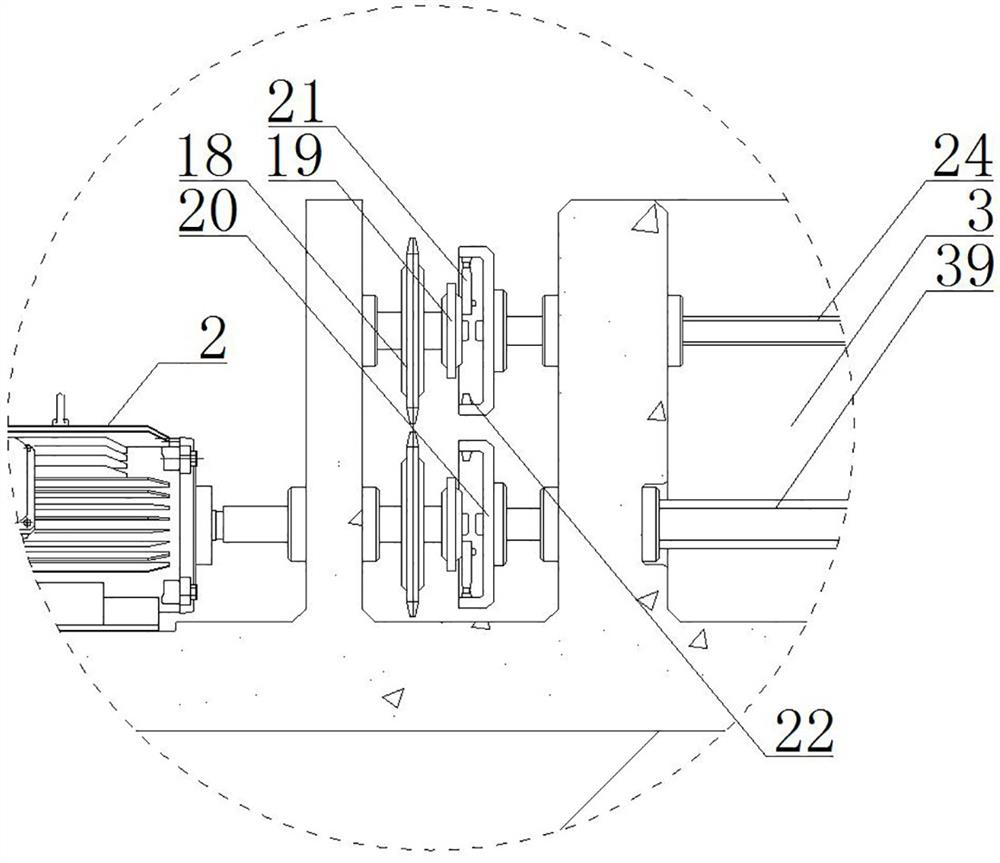

[0038] see Figure 1-8 , and the present invention will be further supplemented and explained in conjunction with Embodiment 1. The installation box 1 is fixed with an installation vertical plate, and two sets of transmission sprockets 18 are rotatably installed on the installation vertical plate, and the two sets of transmission sprockets 18 are realized by chains. Chain drive, the rotating shaft of the driving motor 2 is fixedly connected with one of the group of transmission sprockets 18, the two sets of transmission sprockets 18 are fixed with a rotating disk 19 at the shaft center, and the outer wall of the first chute 3 is fixed with a rotating disk 19. The two sets of mounting disks 20 are horizontally opposite to the disk 19. The outer edge of the rotating disk 19 is rotatably installed with a pawl 21, and the pawl 21 and the rotating disk 19 are matched with a reed, and the inner side wall of the mounting disk 20 is evenly fixed. The ratchet teeth 22, the ratchet pawl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com