Biomass particle power generation device

A technology for biomass pellets and power generation devices, which is applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of cumbersome activated carbon replacement process, time-consuming and labor-intensive excrement, and achieve the goal of reducing excrement residue and improving recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

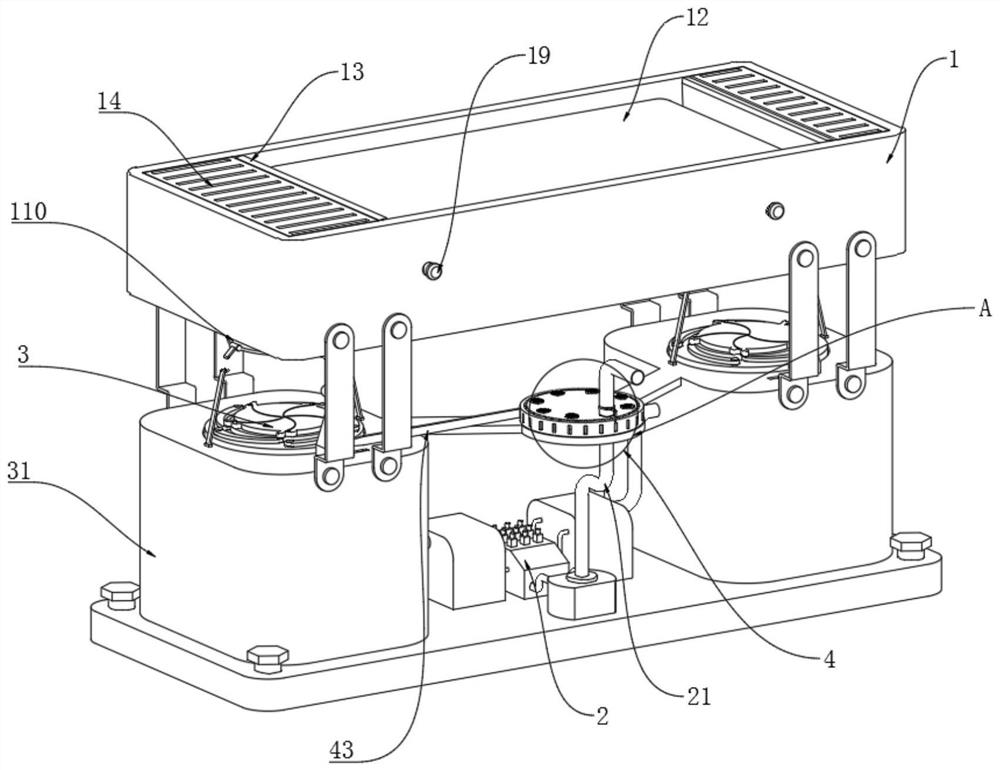

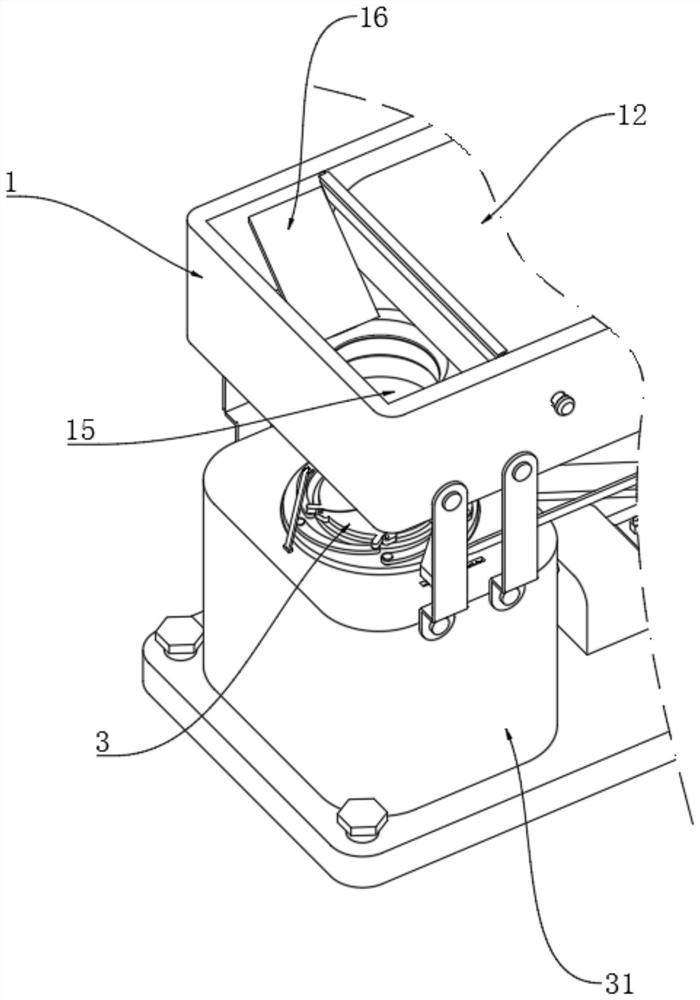

[0031] Please refer to figure 1 and Figure 5 As shown, the material storage mechanism 3 includes a collection bucket 31, a sealing turntable 32, a connecting rod 33, a sealing plate 34, a push block 35, a ball head abutting rod 36, and a triggering oblique strip 37. The bottoms of the front and rear sides of the installation bin 1 are both A collection bucket 31 is symmetrically and fixedly installed. The collection bucket 31 is an open body structure, and a sealing turntable 32 is rotatably connected to the open upper surface of the collection bucket 31. The front side of the sealing turntable 32 is located on the upper side of the collection bucket 31. The surface is provided with a push block 35, the bottom of the push block 35 is slidingly connected to the upper surface of the collecting bucket 31 through a spring, one side surface of the push block 35 is inclined, and the lower end of the push block 35 is at the inclined surface of the push block 35. On the same vertica...

Embodiment 2

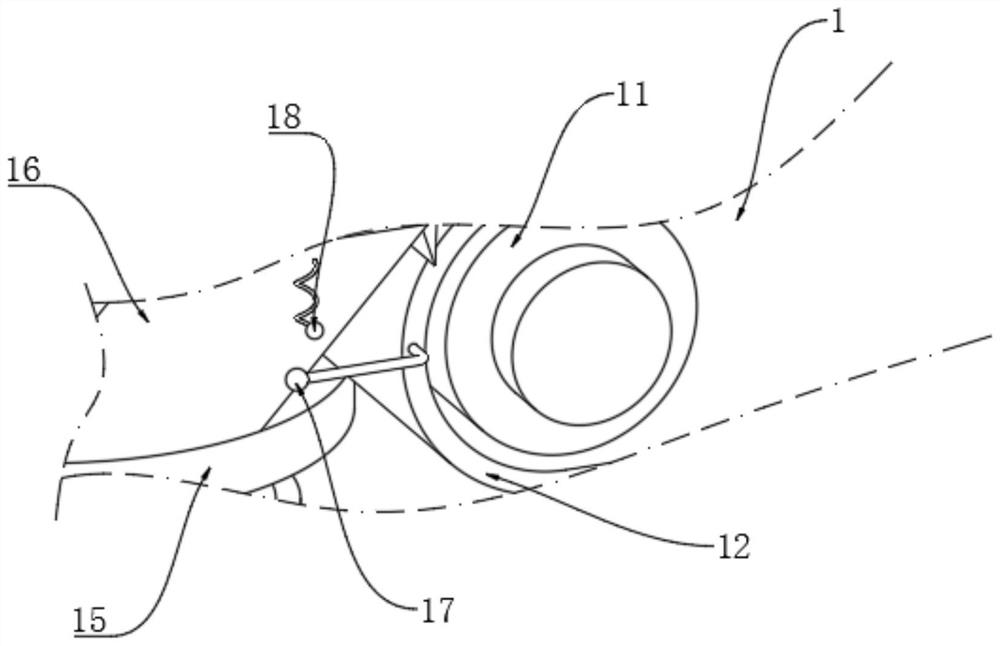

[0034] Please refer to figure 1 and figure 2 As shown, the installation bin 1 includes a rotating shaft 11, a conveyor belt 12, an attached scraper 13, a baffle plate 14, a blanking port 15, a material guide inclined plate 16, a ball-end curved shaft 17, a spring ball 18, an adjustment bolt 19, and a material storage The cavity 110, the turning ear 111, the winding shaft 112, and the suspending rope 113. The installation bin 1 is a cavity structure. The front and rear sides of the installation bin 1 are symmetrically provided with a rotating shaft 11. Bolts 19, the outer ends of the adjusting bolts 19 are placed outside the installation bin 1, the outside of the rotating shaft 11 is installed with a conveyor belt 12, both sides of the conveyor belt 12 are provided with attached scrapers 13, and the bottom surface of the attached scraper 13 is inclined There is a gap between the inner surface of the attached scraper 13 and the conveyor belt 12. The attached scraper 13 is conn...

Embodiment 3

[0038] Please refer to Figure 1 to Figure 6 As shown, a biomass particle power generation device includes an installation bin 1, a generator set 2, a material storage mechanism 3, and an adsorption mechanism 4. A generator set 2 is arranged below the installation bin 1, and the installation bin 1 includes a rotating shaft 11, Conveyor belt 12, attached scraper 13, baffle plate 14, material blanking port 15, material guide inclined plate 16, ball-end curved shaft 17, spring ball 18, adjusting bolt 19, material storage cavity 110, turning ear 111, winding shaft 112 , hanging rope 113, the installation bin 1 is a cavity structure, the front and rear sides of the installation bin 1 are symmetrically provided with a rotating shaft 11, and the center position of the front and rear sides of the rotating shaft 11 is inserted with an adjusting bolt 19, and the outer end of the adjusting bolt 19 is arranged A conveyor belt 12 is installed on the outside of the installation bin 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com