Online monitoring and alarming system, method and device for elevator steel wire rope

An alarm system and wire rope technology, applied in the field of elevators, can solve problems such as unchangeable data judgment and processing, impact on elevator safety operation, and large manpower and time consumption, so as to improve equipment maintenance efficiency, ensure life and property safety, and prolong life. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

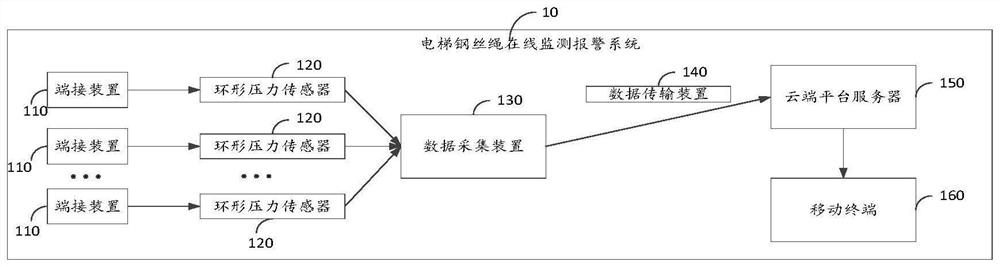

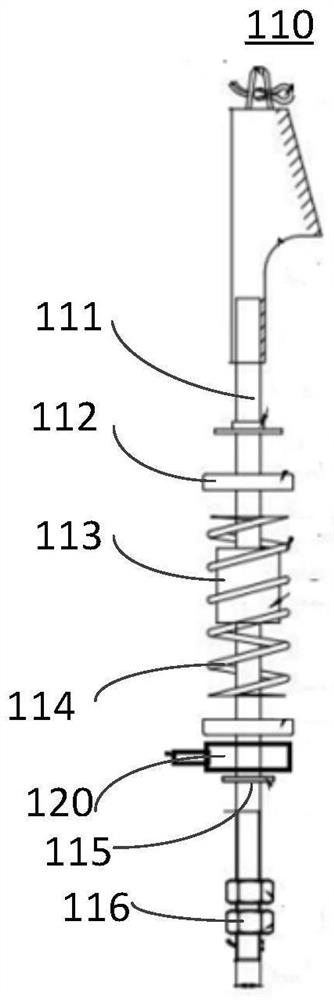

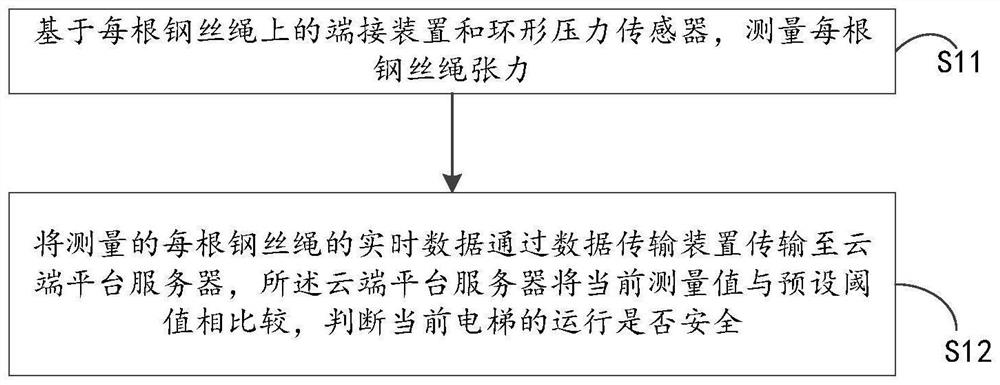

[0028] The technical solutions in the present application will be described below with reference to the accompanying drawings.

[0029] The elevators currently in operation are inspected and maintained by elevator maintenance personnel according to fixed periods and fixed items. According to the current maintenance rules, the elevator wire rope tension is generally checked every quarter, and there are differences in the actual equipment status inspection on site due to the difference in the technical level of elevator maintenance personnel. Happening.

[0030] The service life of the elevator wire rope is directly related to the uniformity of the force, because the elevator wire rope is not evenly stressed, no matter the force is small or the force is large, it will lead to different degrees of wear of the wire rope. When it is large, it will cause inconsistent wear of the traction sheave, and eventually lead to the scrapping of the wire rope and the traction sheave. As long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com