Methanol liquid phase reforming hydrogen production device and method and power supply system

A liquid phase reforming and hydrogen production device technology, applied in chemical instruments and methods, solar heating systems, hydrogen, etc., can solve the problems of increased risk, complex internal structure and processing technology, and high risk, so as to improve safety , Simple structure, good load-bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

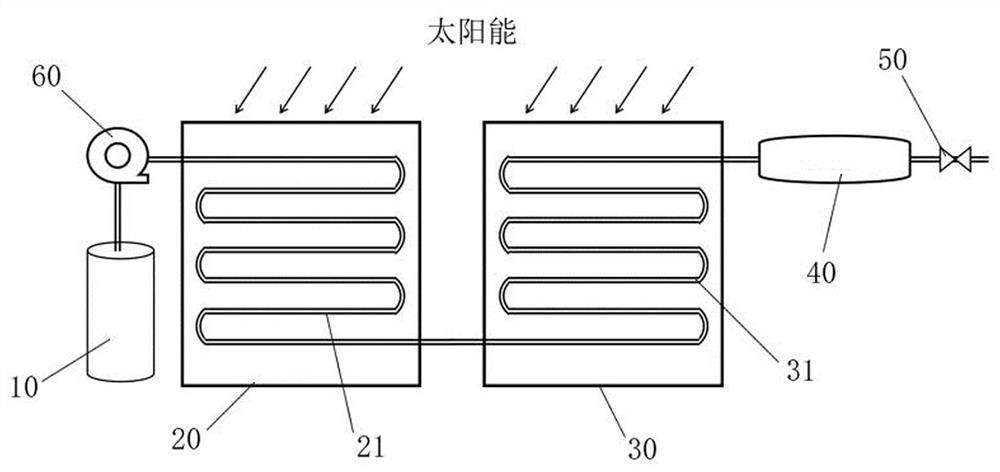

[0075] use figure 1 In the methanol liquid-phase reforming hydrogen production device of the embodiment shown, the coil P is serpentine, and the coils P of the first solar flat panel heat collector 20 and the second solar flat panel heat collector 30 are connected in series. The methanol aqueous storage tank 10 stores a mixed solution of methanol and deionized water prepared in advance, and the concentration of the solution is 45 wt%. Provide methanol aqueous solution with a predetermined pressure of 2.0MPa, the first solar flat panel heat collector 20 is set to heat the methanol aqueous solution to 40°C, the second solar flat panel heat collector 30 is set to heat the methanol aqueous solution to 150°C, and the catalyst is Pt / α-MoC. The gas produced by the liquid phase reforming is hydrogen with a CO content of 91ppm, and the gas pressure is 2.0MPa.

Embodiment 2

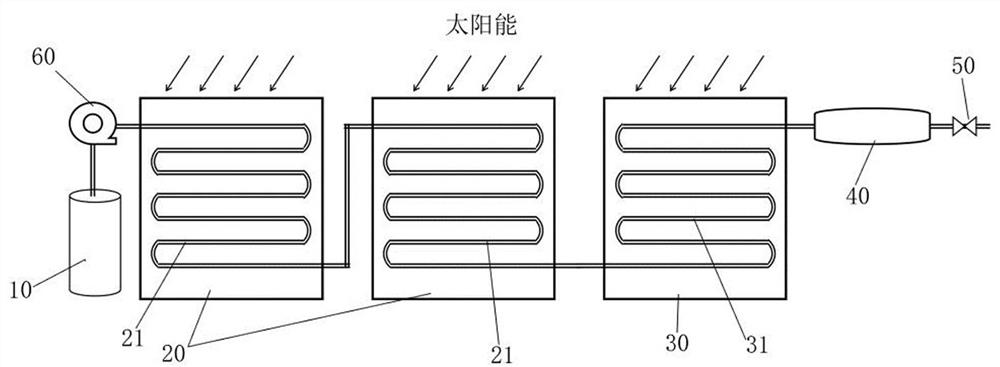

[0077] use figure 2 In the methanol liquid-phase reforming hydrogen production device of the embodiment shown, the coil P is serpentine. The concentration of the solution stored in the aqueous methanol storage tank 10 is 50 wt%, and the aqueous methanol solution is supplied at a predetermined pressure of 5.0 MPa. The two first solar flat panel heat collectors 20 are set to heat methanol aqueous solution to 80°C and 150°C, the second solar flat panel heat collector 30 is set to heat methanol aqueous solution to 190°C, and the catalyst is Cu@C. The gas produced by the liquid phase reforming is hydrogen with a CO content of 79ppm, and the gas pressure is 5.0MPa.

Embodiment 3

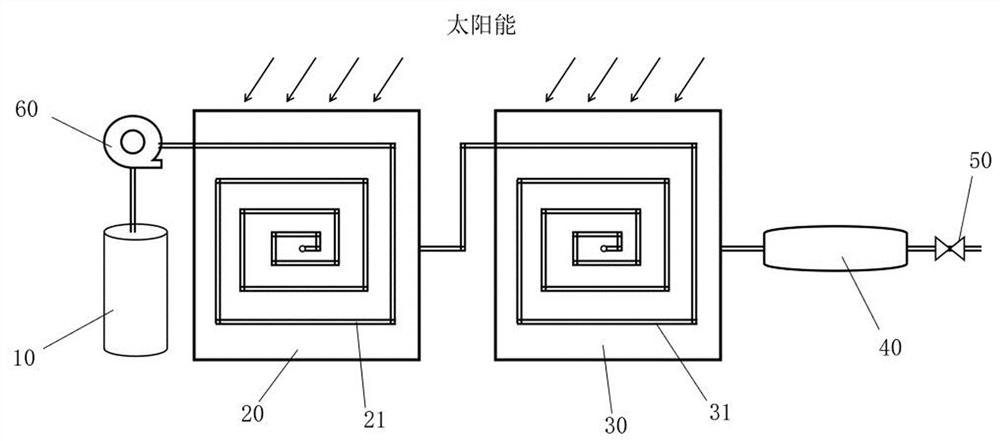

[0079] use image 3 In the methanol liquid-phase reforming hydrogen production device of the embodiment shown, the coil P is in a spiral shape. The concentration of the solution stored in the aqueous methanol storage tank 10 is 55 wt%, and the aqueous methanol solution is supplied at a predetermined pressure of 7.0 MPa. The first solar flat panel heat collector 20 is set to heat the aqueous methanol solution to 130°C, the second solar flat panel heat collector 30 is set to heat the aqueous methanol solution to 210°C, and the catalyst is Cu / ZnO / Al 2 o 3 . The gas produced by the liquid phase reforming is hydrogen with a CO content of 77ppm, and the gas pressure is 7.0MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com