Full-automatic treatment device for deep denitrification of sewage/wastewater

A technology of automatic water intake and biological denitrification, applied in water/sludge/sewage treatment, biological treatment devices, biological water/sewage treatment, etc., can solve high operation and maintenance costs, difficult management and maintenance, and bubble oxygen utilization High efficiency and other problems, to achieve the effect of eliminating the need for power equipment water pumps and aeration devices, good working and living environment, and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

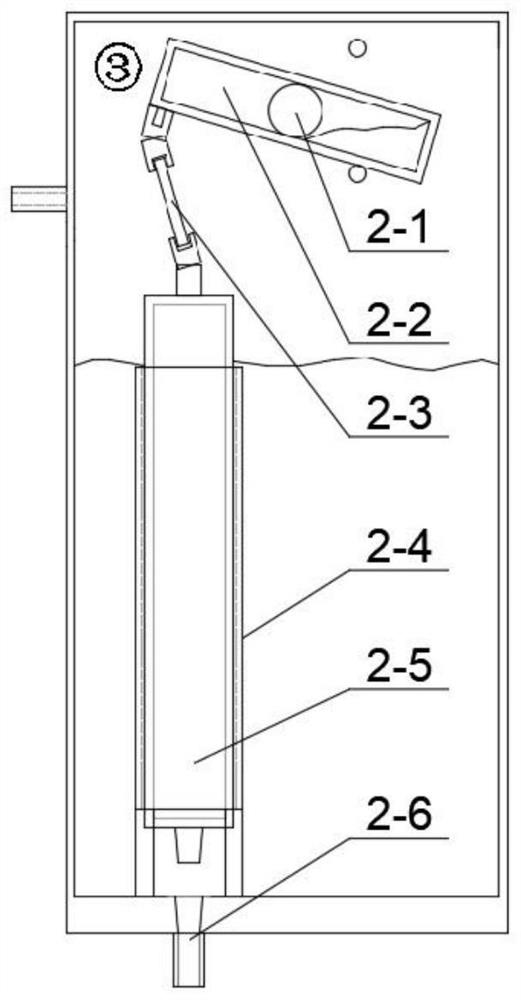

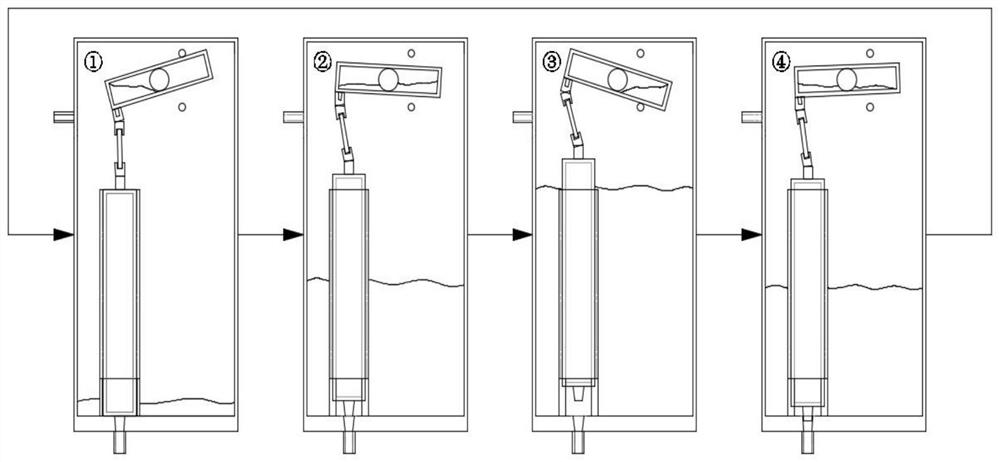

[0032] see figure 2 , In this example, the hydraulic control valve includes liquid storage, supports, connecting rods, guide rods, guide rails and universal joints. The liquid storage 2-2 is connected with the water storage tank through the support 2-1, the guide rod 2-5 is connected with the liquid storage 2-2 through the universal joint 2-3, and the guide rod 2-5 is limited by the fixed shaft 2-4. , the bottom of the guide rod 1-8 is connected with the water outlet 1-11 at the bottom of the water storage tank.

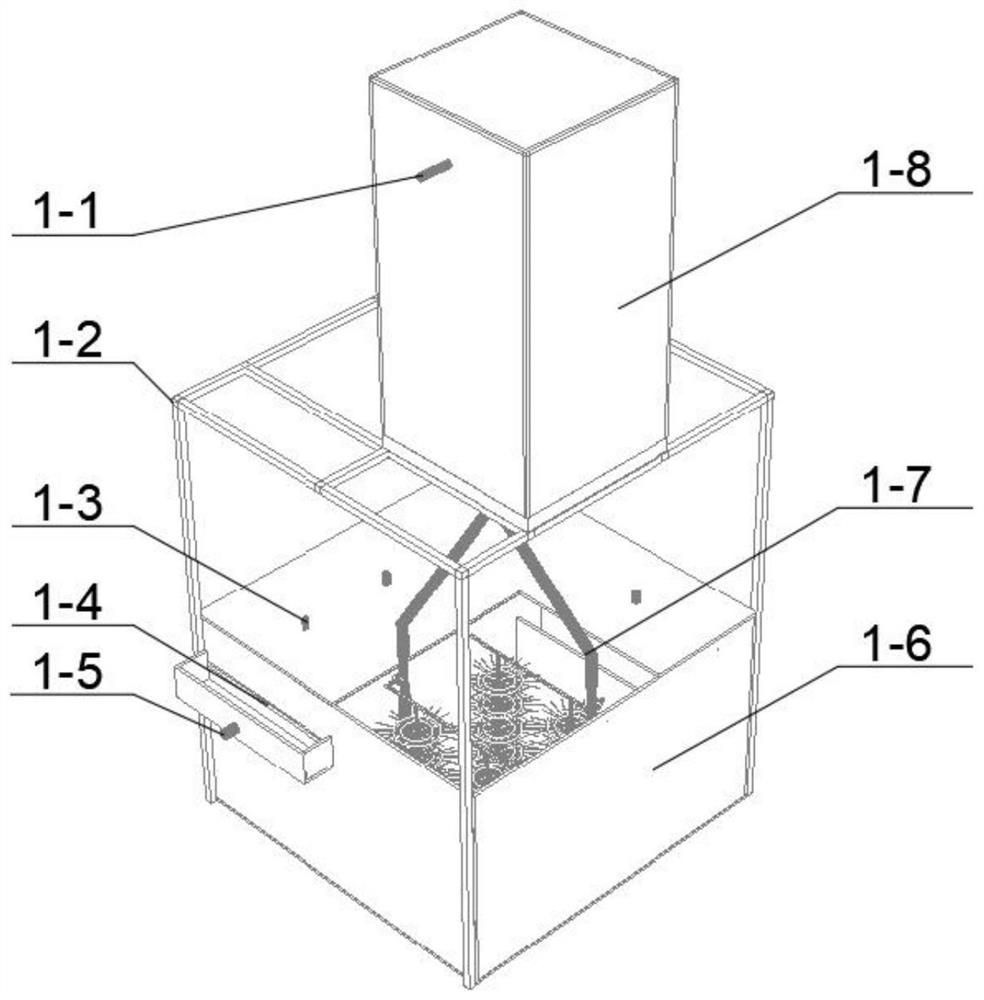

[0033] see figure 1 , figure 2 , The automatic water inlet system in this example is characterized in that: the water inlet pipe in the automatic water inlet system is connected to the water inlet 1-1 of the water storage tank, the hydraulic control valve is fixed in the water storage tank through the support 2-1, and the bottom o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com