Desert sand concrete with high substitution rate as well as preparation method and application of desert sand concrete

A desert sand, replacement rate technology, applied in the field of building materials, can solve the problems of performance improvement, etc., to achieve the effect of increasing the replacement rate and fly ash content, improving the anti-chloride ion penetration performance, and improving the anti-chloride ion penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

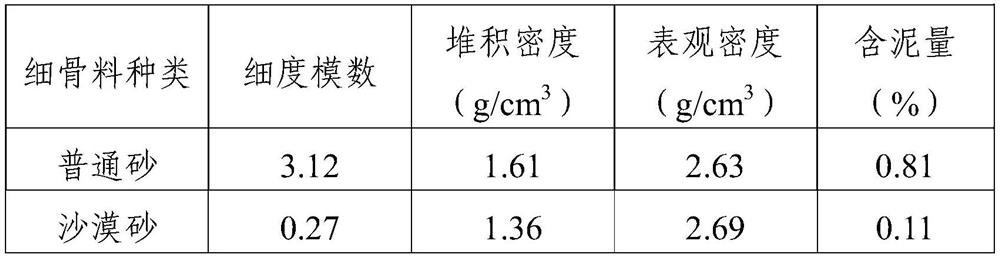

[0034] The present embodiment provides a desert sand concrete with a high substitution rate, and the raw materials are as follows: the cement adopts P.O 42.5R cement produced by Conch Cement Co., Ltd.; the fly ash adopts II grade fly ash. The fine aggregates are respectively used: ordinary sand with a fineness modulus of 3.12 and ultra-fine desert sand with a fineness modulus of 0.27. The physical properties of the two are shown in Table 1. The coarse aggregate uses a particle size range of 4 -20mm artificial crushed stone, the particle size range of the specific coarse aggregate is shown in Table 2;

[0035] Table 1 Physical properties of ordinary sand and desert sand

[0036]

[0037] Table 2 Particle size range of coarse aggregate

[0038] Coarse aggregate Particle size range dashi 19~9.5mm small stone 9.5~4.75mm

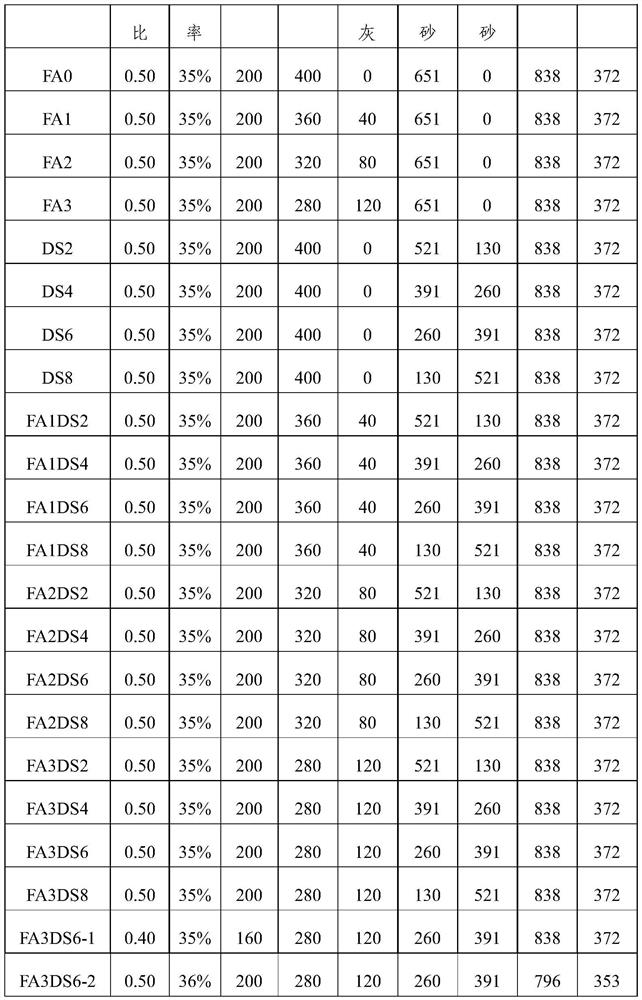

[0039] The design concrete strength grade of the desert sand concrete with high substitution rate in this embodiment is C40, the ...

Embodiment 2-6

[0045] This embodiment provides a desert sand concrete with a high replacement rate, which is different from Example 1 only in that the replacement rate of desert sand and the content of fly ash are: 60% and 10%, 80% and 10%, and 60%, respectively. and 20%, 80% and 20%, 80% and 30%, as shown in Table 3; marked as FA1DS6, FA1DS8, FA2DS6, FA2DS8, FA3DS8, respectively.

experiment example 1

[0058] In this experimental example, the electro-flux method and the RCM method were used to evaluate the resistance to chloride ion penetration of the example and the comparative example respectively. The concrete specimen for the resistance to chloride ion penetration performance test was a cylinder with a diameter of 100 mm and a height of 50 mm, with a total of 9 in each group. According to the electric flux method and RCM (rapid chloride ion migration coefficient) method in the standard "Standard for Long-term Performance and Durability Performance of Ordinary Concrete" GB / T50082-2009, measure the 0% and 3% of each concrete specimen respectively. , electric flux and chloride ion diffusion coefficient in 6% NaCl solution. The test results are shown in Table 4.

[0059] The electric flux and chloride ion migration coefficient of concrete provided by the embodiment and comparative example of table 4

[0060]

[0061]

[0062] The desert sand replacement rate and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com