Dust removal device for knitted fabric processing

A dust removal device and technology for knitted fabrics, applied in textiles and papermaking, using liquid separators, mechanical cleaning, etc., can solve the problems of knitted fabrics with a lot of dust, and achieve the effects of increased dust removal efficiency, simple structure, and good dust removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

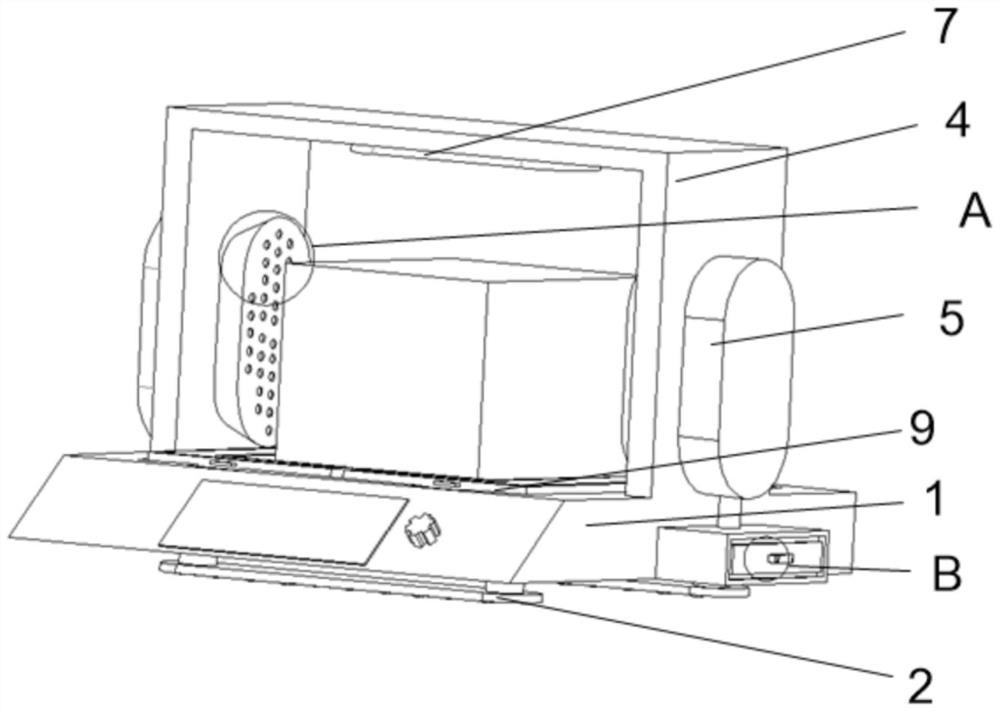

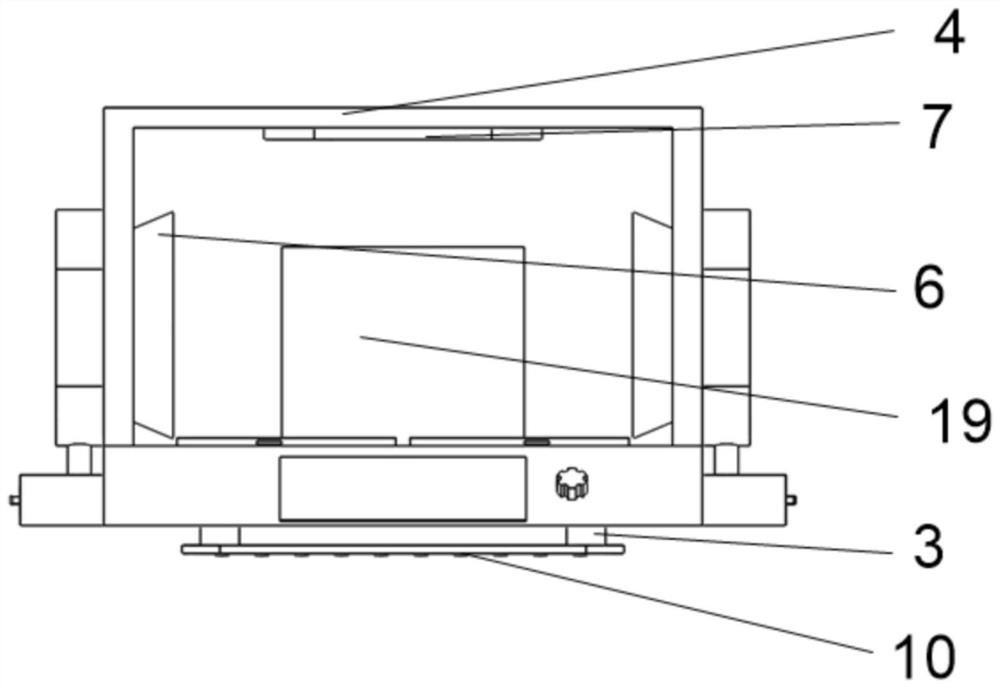

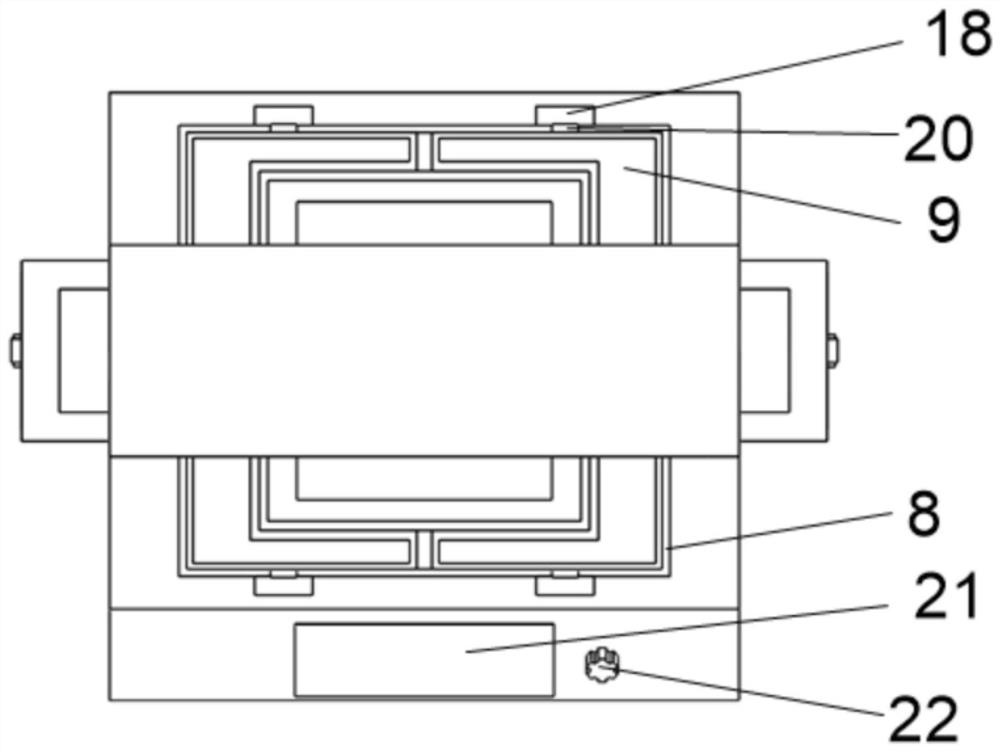

[0030] In the present embodiment I, reference Figure 1-Figure 6, the lower side of the dust removal base 1 is provided with a support device 2, the support rod 3 of the support device 2 is connected with the base plate of the dust removal base 1, the support rod 3 is equipped with a skid plate 10, the skid plate 10 is oval, the oval skid plate 10 can provide a larger support surface, the lower side of the skid plate 10 is equipped with a friction bar, which can provide better anti-slip support for the equipment, the dust removal base 1 is equipped with a dust collection bracket 4, the dust collection bracket 4 side is equipped with a dust collection device 5, and the suction port of the dust collection device 5 is located on the side of the dust collection bracket 4. Vacuum cleaner 6 front side is provided with filter plate 11, filter plate 11 front side open filter hole 12, suction port 6 rear side is provided with dust collector 13, dust collector 13 fixed to the dust collection...

Embodiment 2

[0032] In the present embodiment II, reference is made Figure 1-Figure 6 , the staff first start the dust collector 5 of the dust collector 13, and then start the knitting device 19, the staff observe the amount of dust generated by the knitting device 19, and then adjust the power of the dust collector 13 by rotating the button 22, the dust on the upper side enters the storage box 15 from the suction port 6 of the dust collector device 5, the dust on the lower side falls into the sedimentation tank 9, when the storage box 15 is full, the staff will remove the storage box 15 by handle 16, when the sedimentation tank 9 needs to replace the water, The staff removes the sediment tank 9 by grabbing handle 20.

[0033] Beneficial technical effects on the embodiment of the present invention are: since the device is provided with a dust collector, and the suction port of the dust collector is round table shaped, the dust removal efficiency of the equipment is increased, and the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com