Long-wall mining separation layer grouting drill hole arrangement method

A technology of grouting drilling and layout method, which is applied in mining equipment, earthwork drilling, safety devices, etc., and can solve problems such as grouting filling failure and easy hole plugging, so as to reduce difficulty, increase reliability and timeliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

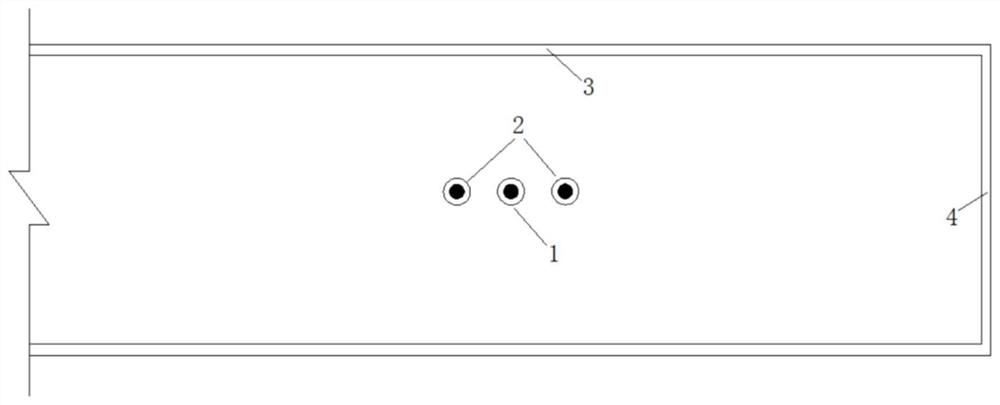

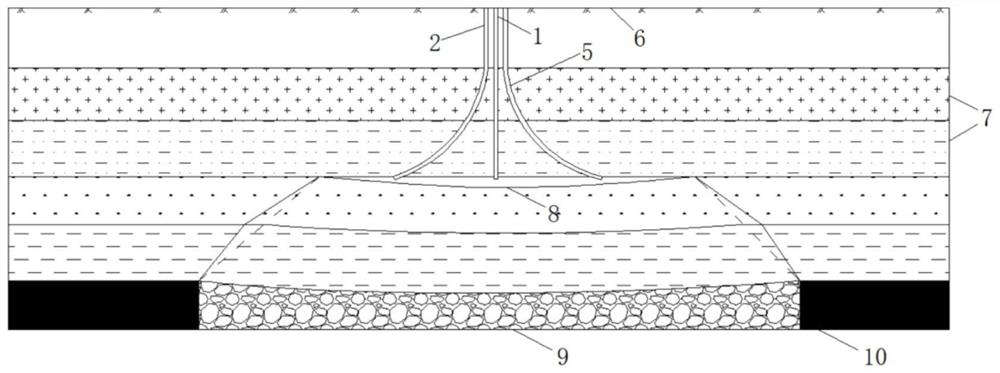

[0026] The invention provides a method for arranging grouting drilling holes for long-wall mining separation layers, which solves the problem that a single drilling hole is easy to block holes in the traditional grouting and filling process, which leads to the failure of grouting and filling, and increases the reliability of the grouting and filling system. At the same time, dispersed grouting through three grouting drilling holes can make the slurry flow range larger, ensure that the designed grouting filling amount is achieved, and the grouting filling effect can be ensured. Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0027] combine figure 1 , figure 2 As shown in the figure, a method for arranging drilling holes for separation layer grouting in long-wall mining, comprising:

[0028] Drill the main grouting hole 1 to the separation layer 8 from the ground 6 in the middle of the layer separation area, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com