Condensate water draining device

A condensed water and hydrophobic technology, which is applied in the field of steam traps, can solve the problems of low hydrophobic efficiency, small capacity of steam traps, and steam discharge, etc., and achieve the effects of improving economic benefits, improving recycling rates, and high hydrophobic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Due to the special structure of the existing steam trap, it is easy to cause a part of the steam to be discharged during the drainage process. These steam-water mixtures are discharged into the workshop, which will affect the reuse rate of condensed water; and the capacity of the steam trap is small, which can The pressure of condensed water is also small, which cannot meet the requirements of hydrophobicity under high-power conditions, and the hydrophobicity efficiency is low; The generated steam will be discharged to the outside of the equipment, and the secondary utilization of the flash steam cannot be carried out, and the economic benefit of the enterprise is low.

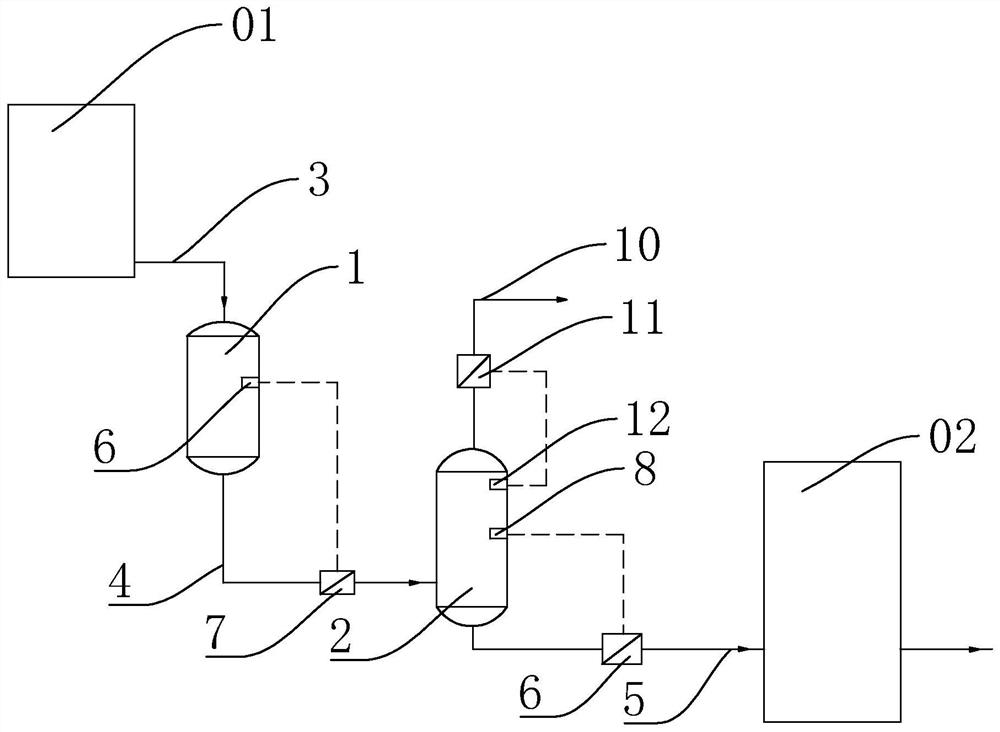

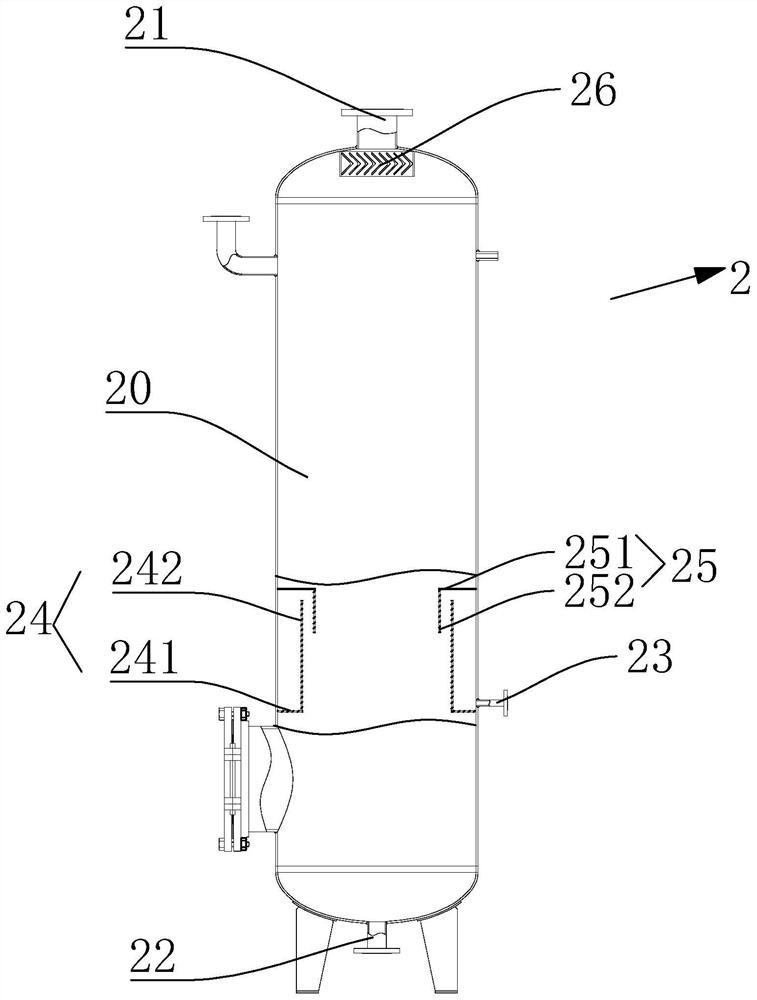

[0025] In order to solve the above-mentioned technical problems, a condensed water draining device provided in this embodiment 1, such as figure 1 As shown, it includes a first tank 1 and a second tank 2 that are communicated in sequence; the top and bottom of the first tank 1 and the second tank 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com