Layered sampling system for underground water monitoring

A sampling system and hierarchical technology, applied in sampling devices, general water supply conservation, cleaning methods using tools, etc., can solve the problems of easy adsorption of wire ropes, ground subsidence, low efficiency, etc., to avoid inaccurate monitoring and improve accuracy. , to ensure the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

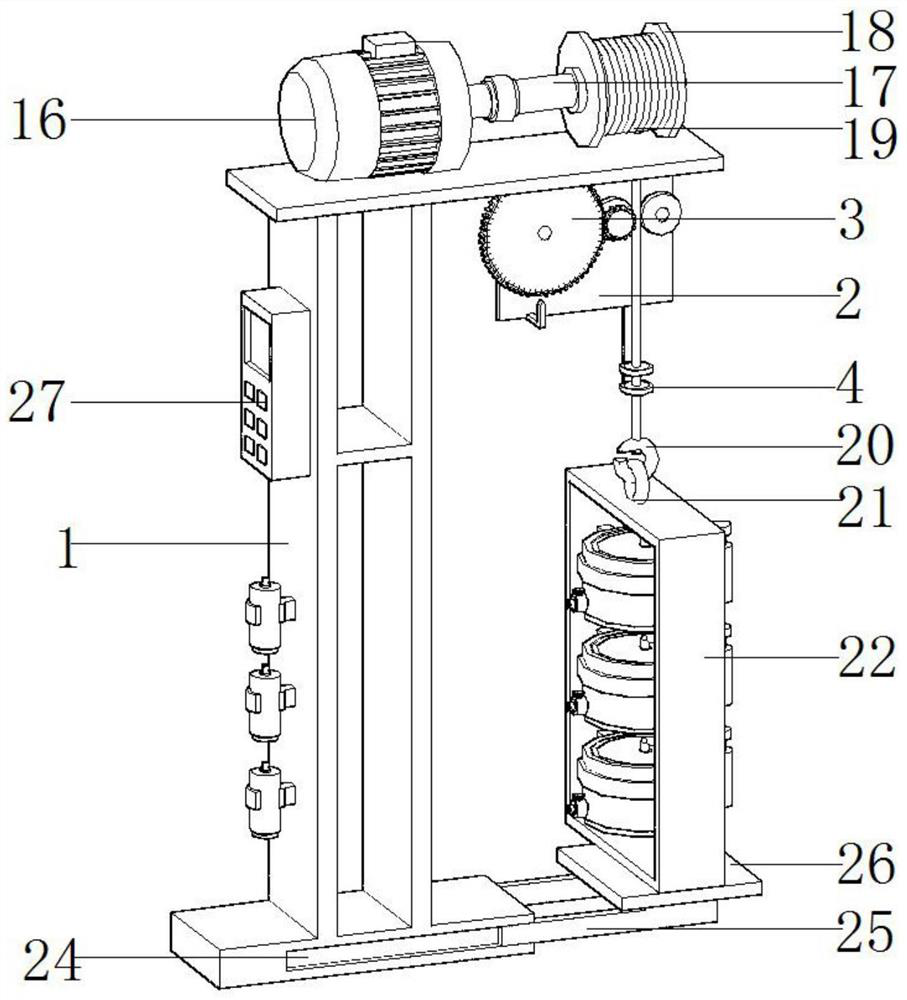

[0032] Example 1, refer to Figure 1-7 , a layered sampling system for groundwater monitoring, including a fixing frame 1, in order to realize the winding of the wire rope 19 through the rotation of the output shaft of the servo motor 16, the outer wall of the top of the fixing frame 1 is fixedly connected with the servo motor 16 by bolts, and The output shaft of the servo motor 16 is connected with a main shaft 17 through a coupling, the outer wall of the main shaft 17 is fixedly connected with a winding roller 18, and the inner wall of the winding roller 18 is wound with a wire rope 19;

[0033] In order to fix the fixing frame 22 on the bottom of the wire rope 19, a hook 20 is connected to the outer wall of one end of the wire rope 19, and the outer wall of the hook 20 is hung with a hanging ring 21, and the outer wall of the bottom of the hanging ring 21 is welded with a fixing frame 22;

[0034] In order to describe the specific installation positions of the collecting cy...

Embodiment 2

[0037] Example 2, refer to Figure 1-2 , this embodiment is optimized on the basis of Embodiment 1, specifically:

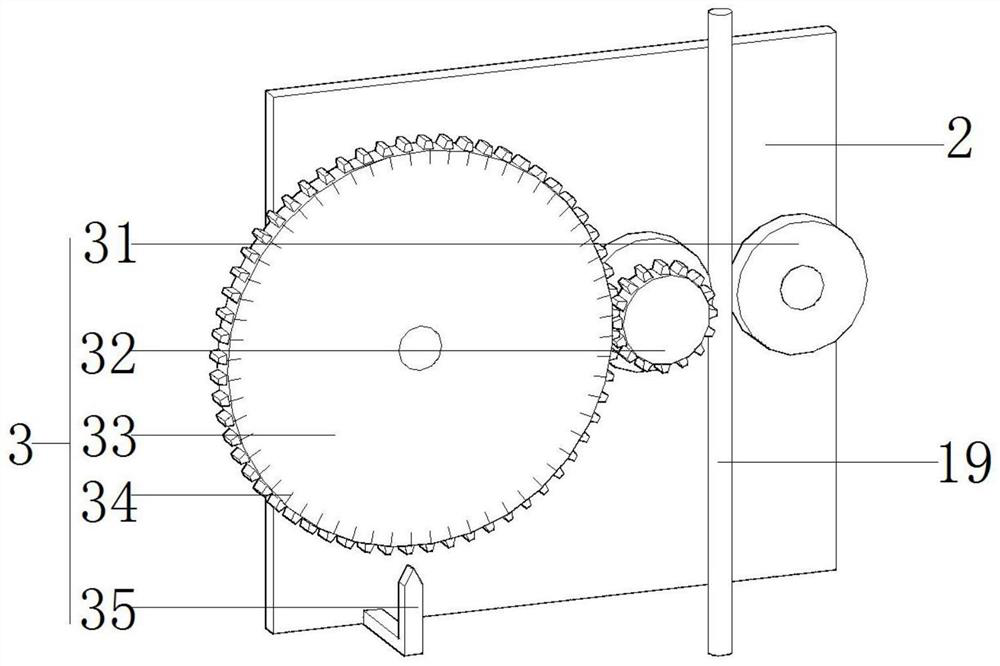

[0038]The inner wall of the top of the fixing frame 1 is welded with a back plate 2, and the outer wall of one side of the back plate 2 is provided with a positioning mechanism 3. The positioning mechanism 3 includes a positioning wheel 31, a first gear 32, a second gear 33, a scale line 34, and an indicator arrow 35. The first gear 32 is fixedly connected to one side of the outer wall of one of the positioning wheels 31, the second gear 33 is engaged with the outer wall of the first gear 32, the scale line 34 is glued to the outer wall of the second gear 33, and the indicating arrow 35 is welded. On the bottom of one side outer wall of the back plate 2, since the wire rope 19 is located between the two positioning wheels 31, when the wire rope 19 moves downward, it will drive the two positioning wheels 31 to rotate, and one of the positioning wheels 31 will driv...

Embodiment 3

[0039] Example 3, refer to Figure 1-3 , this embodiment is optimized on the basis of Embodiment 1, specifically:

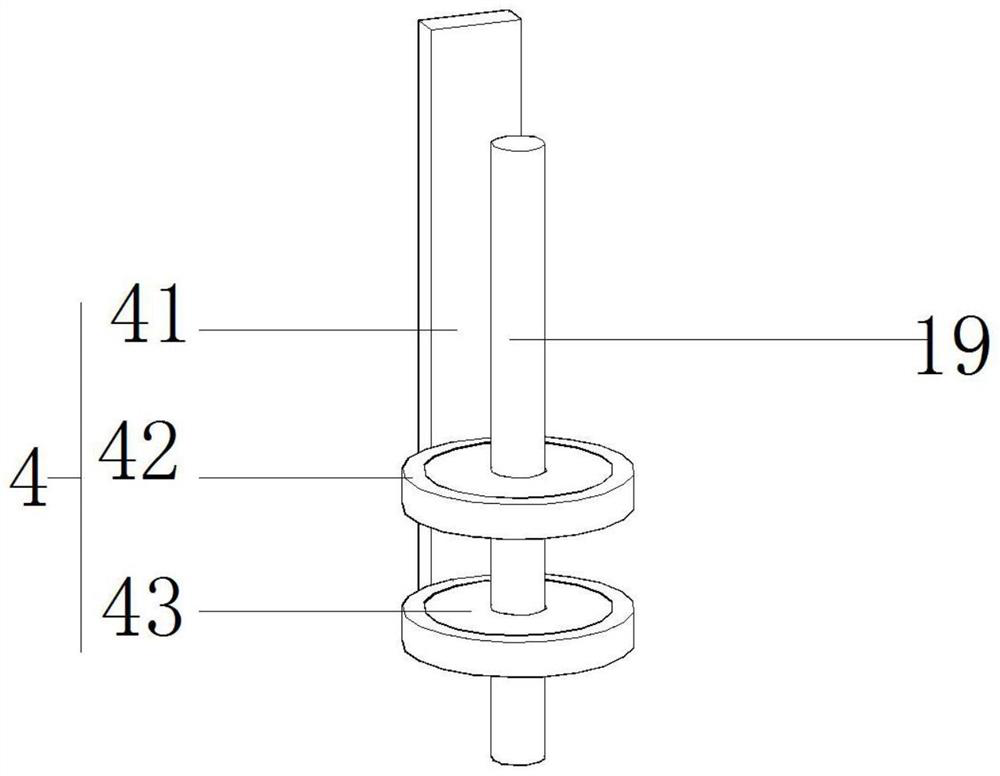

[0040] The bottom outer wall of the back plate 2 is provided with a cleaning mechanism 4, and the cleaning mechanism 4 includes a support rod 41, a mounting ring 42, and a snap ring 43. The symmetrically distributed mounting rings 42 are welded to the outer wall of one side of the support rod 41, and the snap ring 43 is bonded On the inner wall of the mounting ring 42, when the fixing frame 22 moves upward, the wire rope 19 will be continuously reeled onto the winding roller 18, and the wire rope 19 will pass through the snap ring 43 at this time. Contact, not only can clean up the stolen goods attached to the surface of the wire rope 19 to ensure the cleanliness of the wire rope 19, but also can clean up the water stains on the surface of the wire rope 19 to avoid the problem of rusting caused by excessive moisture on the surface of the wire rope 19.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com