Maintenance device for micro motor

A technology for overhauling devices and micro motors, which is applied to electromechanical devices, manufacturing motor generators, cooling/ventilating devices, etc. Improve the scope of use, good protection, good observation and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

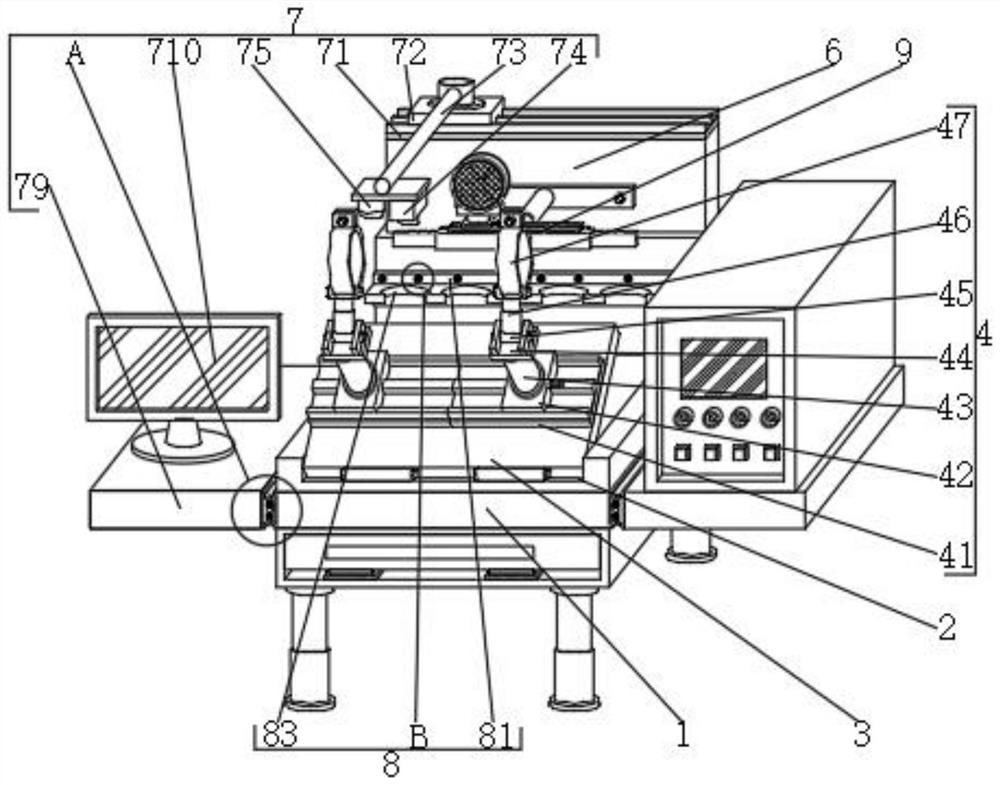

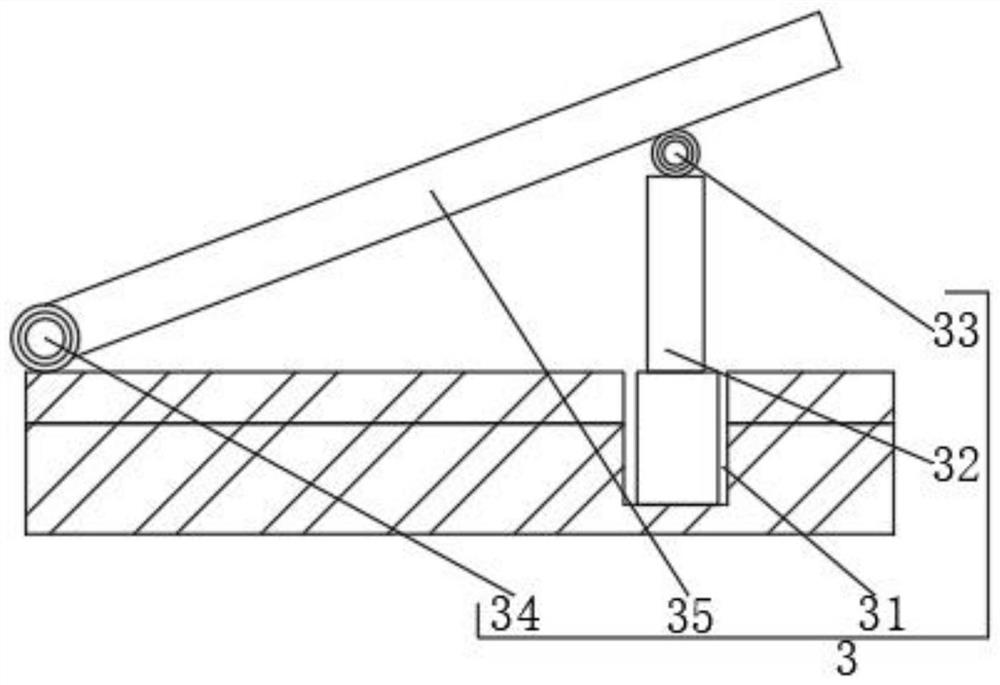

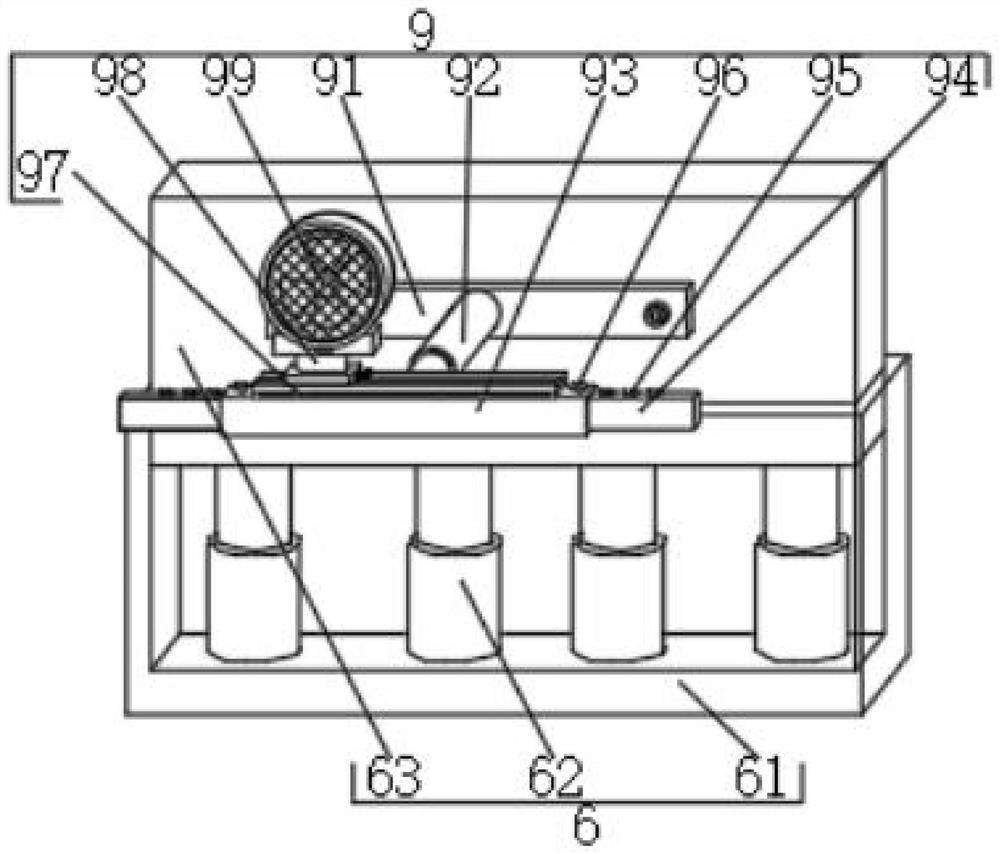

[0032] see Figure 1-6 , In the embodiment of the present invention, an overhaul device for a micro motor includes: an overhaul platform 1 and a mounting slot 2 on the top of the overhaul platform 1, and is characterized in that it also includes an angle adjustment mechanism 3, a shock absorption protection mechanism 5 , the lifting mechanism 6 and the storage mechanism 8, the angle adjustment mechanism 3 is fixedly installed on the top of the installation groove 2, and the shift fixing mechanism 4 is fixedly installed on one side of the angle adjustment mechanism 3; The first connecting plates 41 on both sides of the top of the mechanism 3, the two screw slides 42 fixedly installed on the tops of the two first connecting plates 41, and the two sliding blocks fixedly installed on the tops of the two screw slides 42 respectively The first support rod 43; the shock absorption protection mechanism 5 is fixedly installed on the inner side of the displacement fixing mechanism 4, th...

Embodiment 2

[0034] see figure 1 and Image 6 , and the difference from Embodiment 1 is: a maintenance device for micro-motors, including: the observation mechanism 7 also includes a display 710, two mounting plates 76 fixedly installed on both sides of the two maintenance platforms 1, two There are card slots 77 respectively opened on one side of the two mounting plates 76 , two card blocks 78 fitted on the inner sides of the two card slots 77 , and two support platforms 79 fixed on one side of the two card blocks 78 , respectively. The display 710 is fixedly installed on the top of one of the support platforms 79, and the display 710 can be repaired or replaced more conveniently according to the requirements of use, so as to ensure the best observation of the motor. The observation mechanism 7 includes a second connecting plate 71, an electric sliding The rail 72, the mounting bracket 73, the high-definition camera 74 and the fill light 75, the second connecting plate 71 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com