Efficient industrial control protocol analysis method based on deep learning

A technology for industrial control and protocol analysis, applied in neural learning methods, comprehensive factory control, instruments, etc., can solve problems such as inability to efficiently and accurately analyze industrial protocols, achieve high adaptability and scalability, and reduce processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings.

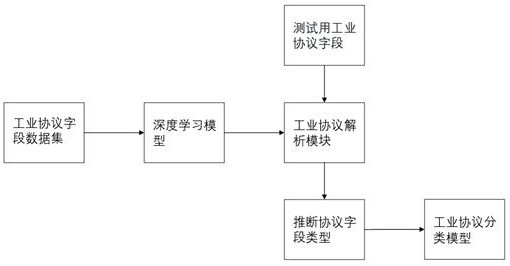

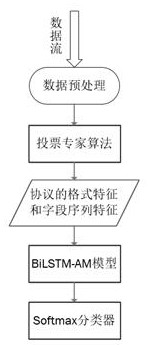

[0034] The process of the present invention is as follows figure 1 shown, the specific steps are as follows:

[0035] S1: Acquisition of industrial protocol data packets. The data packets generated by the actual industrial control system come from the oil and gas gathering and transportation industry simulation platform in the Key Laboratory of Information Security for the Petrochemical Industry of Liaoning Province. The output is in binary form. At the same time, industrial pcap data packets for testing are collected from the github project, Wireshark wiki, etc., including some commonly used industrial control system communication protocols including S7comm, Modbus TCP, PROFIBUS, IEC104, etc.

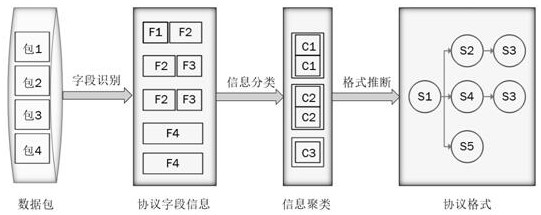

[0036] S2: Infer functional area boundaries and types of protocol fields. The core idea is to obtain the message format by using public field informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com