High-temperature and high-pressure synthesis device and method for diamond hard alloy compact

A technology of cemented carbide and synthesis device, which is applied in the methods of chemically changing substances by atmospheric pressure, chemical instruments and methods, and technological processes applying ultra-high pressure, etc. Affect the spatial uniformity of the thermal field and other problems, and achieve the effect of reducing geometric deformation, reducing heating energy consumption, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

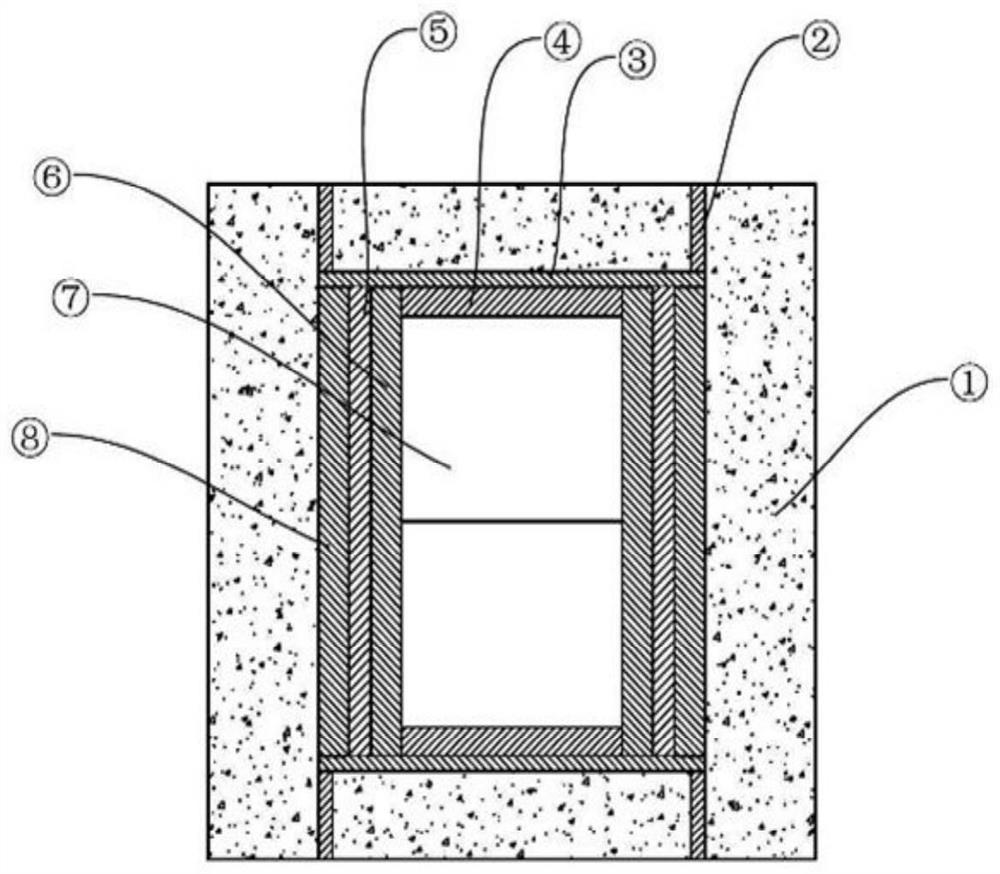

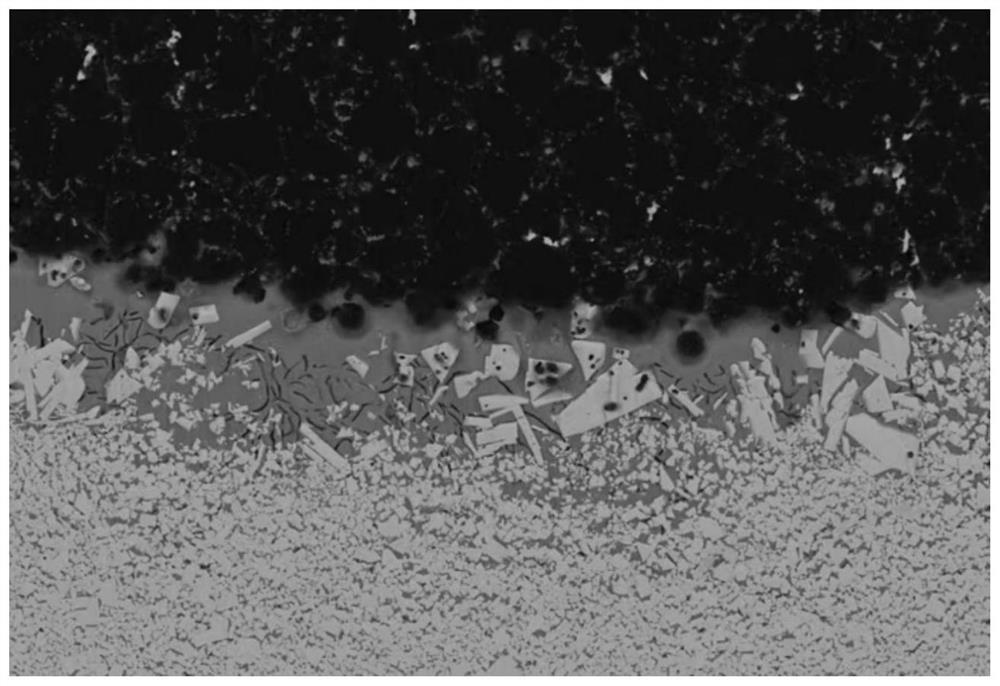

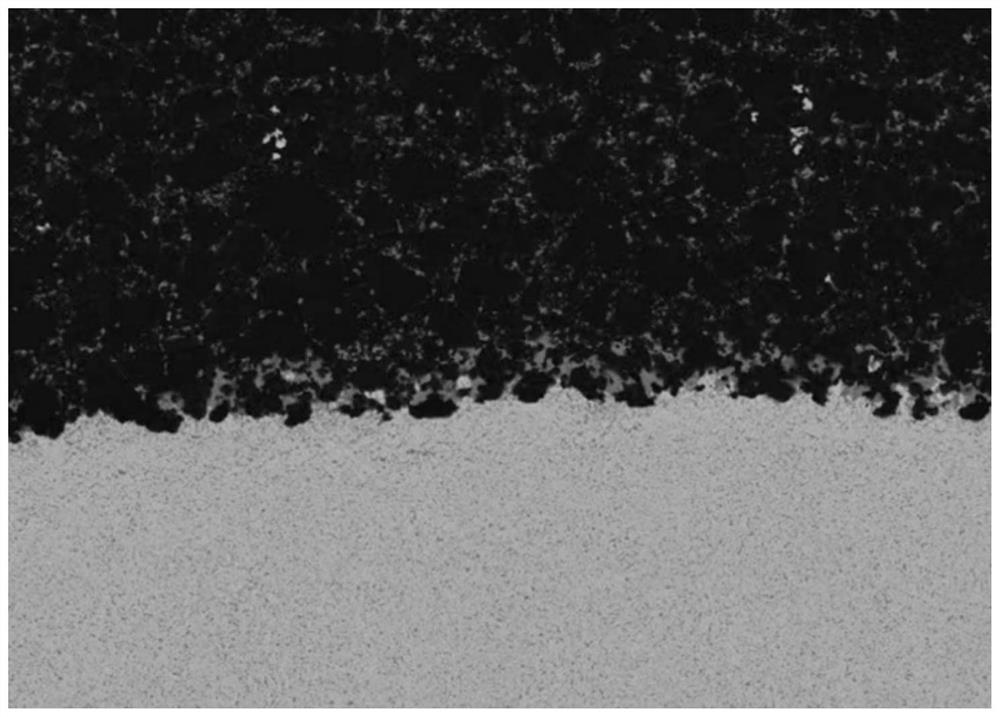

[0054] Adopt the double salt tube structure described in the present invention, the thickness of the inner salt tube is 5mm, high-purity salt is used, the purity of NaCl is not less than 99.5%, the density of the salt tube is 2.15g / cm3; the thickness of the outer salt tube is 2mm, and its composition is 85% NaCl and 15% Cr2O3, the carbon tubes are energized and heated, and after reaching a high temperature, the inner salt tube and the outer salt tube melt to form an inner isostatic pressure pool and an outer isostatic pressure pool; the outer isostatic pressure pool effectively controls the heating of the carbon tubes. deformation, and then make it evenly heated, through the internal isostatic pressure pool to evenly heat the high melting point metal cup, so that the diamond carbide composite sheet obtained after high temperature and high pressure sintering has a uniform structure, such as image 3 As shown, there is no segregation of catalyst Co, no abnormal growth of WC grain...

Embodiment 2

[0056] Adopt double salt tube structure described in the present invention, inner salt tube thickness 3.5mm, adopt high-purity salt, NaCl purity not less than 99.5%, salt tube density 2.15g / cm3; Outer salt tube thickness 4mm, its component is 90 % NaCl and 10% AL 2 o 3 , the carbon tube is energized to generate heat, and after reaching a high temperature, the inner salt tube and the outer salt tube melt to form an inner isostatic pool and an outer isostatic pool respectively. The outer isostatic pressure pool effectively controls the deformation of the heating carbon tube, thereby making it evenly heated, and the high melting point metal cup is evenly heated through the inner isostatic pressure pool, so that the structure of the diamond carbide composite sheet obtained after high temperature and high pressure sintering Uniform, no segregation of catalyst Co, no abnormal growth of WC grains, improved performance, the static pressure strength of the composite sheet reaches Q3, ...

Embodiment 3

[0058] Adopt double-salt tube structure of the present invention, inner salt tube thickness 2.5mm, adopt high-purity salt, NaCl purity not less than 99.5%, salt tube density 2.15g / cm3; Outer salt tube thickness 4.8mm, its component is 92% NaCl and 8% Si 3 N 4 , the carbon tube is energized to generate heat, and after reaching a high temperature, the inner salt tube and the outer salt tube melt to form an inner isostatic pool and an outer isostatic pool respectively. The outer isostatic pressure pool effectively controls the deformation of the heating carbon tube, thereby making it evenly heated, and the high melting point metal cup is evenly heated through the inner isostatic pressure pool, so that the structure of the diamond carbide composite sheet obtained after high temperature and high pressure sintering Uniform, no catalyst Co segregation, no abnormal growth of WC grains, improved performance, the static pressure strength of the composite sheet reaches Q4, as shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com