Soldering flux spraying equipment for new energy automobile liquid cooling plate production

A technology for new energy vehicles and spraying equipment, applied in the direction of spraying devices, etc., can solve the problems of reducing the area and reducing the spraying efficiency, and achieve the effect of reducing the failure rate, improving the spraying efficiency and increasing the spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

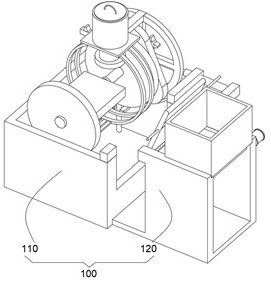

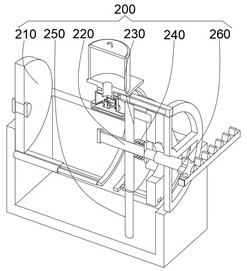

[0047] to combine Figure 1-8 As shown, a flux spraying equipment for the production of new energy automobile liquid-cooled plates provided by the present invention includes a frame module 100, a clamping module 200, a spraying module 300, an anti-blocking module 400 and a feeding module 500, and the frame module 100 includes a frame 110 and a frame 120 connected to the frame 110; the frame 110 plays a role in supporting the entire structure while also recovering flux, improving resource utilization, and the frame 120 is used to raise the height of the loading module 500 , so that the liquid cooling plate can accurately fall between the I-shaped bar and the T-shaped bar 220, making the clamping operation of the liquid cooling plate more convenient;

[0048]The clamping module 200 includes a pressure-bearing component 210 connected to the frame 110, a T-shaped bar 220 installed on the rear side of the pressure-bearing component 210, and the T-shaped bar 220 is used to press aga...

Embodiment 2

[0057] combine figure 1 , 2 , 4 and 8, on the basis of Embodiment 1, a rectangular plate is installed on the rear side of the frame 110, and the rectangular plate and the strap 550 are both sleeved on the outside of the second electric push rod 310, and the rectangular plate and the strap The mutual cooperation of the plates 550 provides the structural strength of the second electric actuator 310 .

Embodiment 3

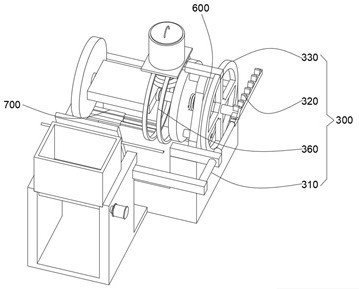

[0059] combine Figure 1-5 As shown, in the above embodiment, a triangular plate 600 is installed on the rear side of the disc body 230, and the triangular plate 600 is located on the front side of the sleeve plate 330, close to the ring body 360 and the triangular plate 600 of the disc body 230 and away from the A telescopic rod 700 is connected between the ring body 360 of the disc 230 and the frame 110, the triangular plate 600 is used to support the telescopic rod 700, and the telescopic rod 700 is set at the same time to ensure that it can Back and forth reciprocating motion.

[0060] The working principle and application process of the present invention: In the initial state, the flux cylinder 381 is filled with flux, then the lead plate 530 is manually turned over, and then the strap 540 is in contact with the strap 550, which is affected by the strap 540 and the strap 550 , the top of the overturned lead plate 530 is located at the same level as the top of the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com