Prefabricated porous cable duct joint device

A technology of cable pipe and joint device, which is applied in the field of prefabricated porous cable pipe joint device, which can solve the problems of uneven cable pipes and inability to connect cable pipes, and achieve the effect of easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

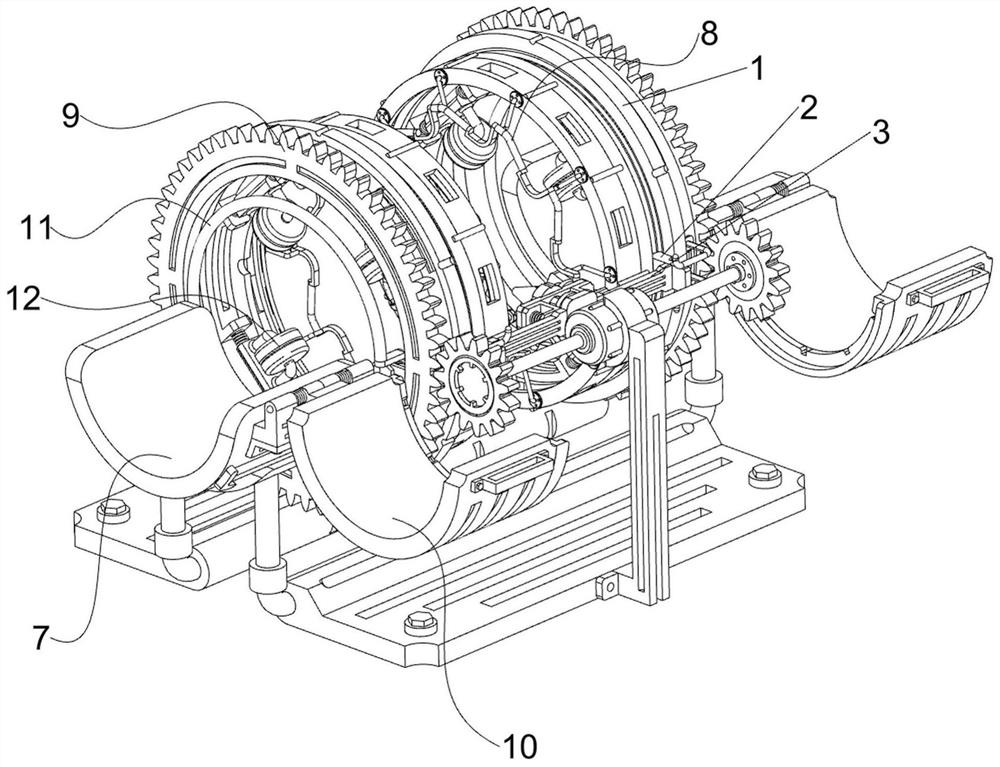

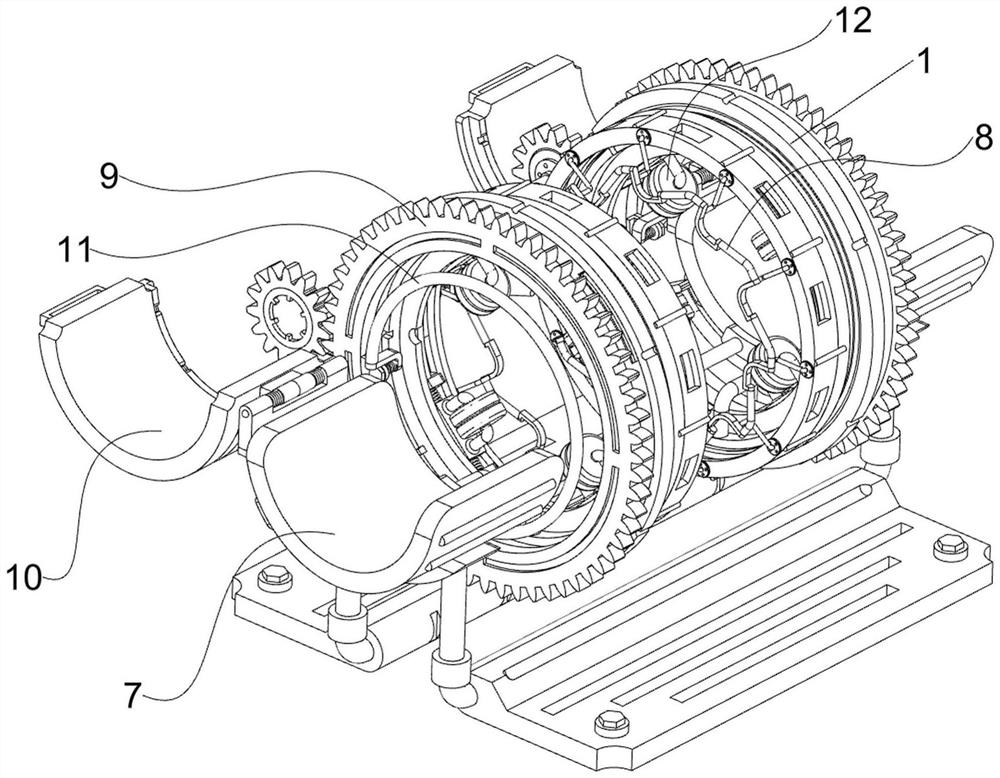

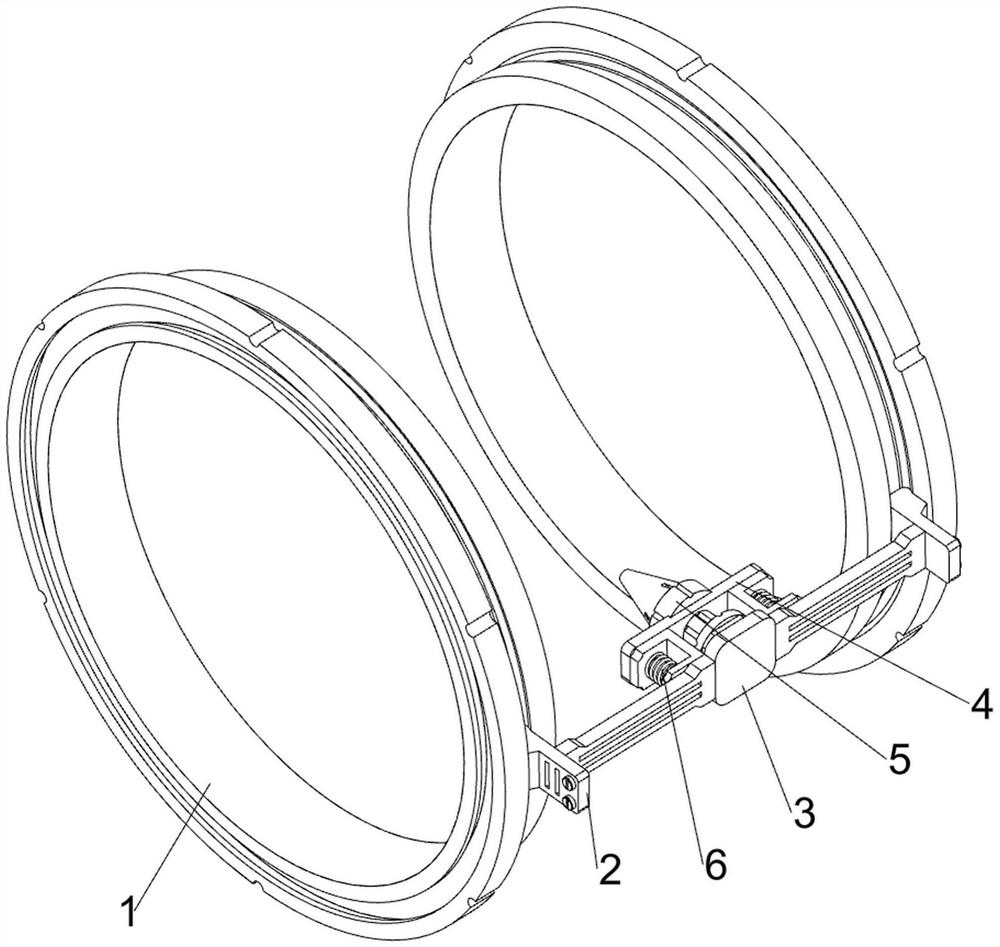

[0070] A prefabricated porous cable pipe joint device, such as Figure 1-Figure 8 As shown, it includes a supporting ring 1, a sliding block 2, a supporting frame 3, a sliding frame 4, a welding machine 5, a return spring 6, a supporting mechanism 7 and a jacking mechanism 8. There are two supporting rings 1, and two supporting rings 1 The sliding block 2 is provided on the right side, and there is damping between the two sliding blocks 2 and the support ring 1 on the same side, so that the sliding block 2 is not easy to move at will. A support frame 3 is arranged between the two sliding blocks 2. Sliding type is provided with sliding frame 4 between the left side of each sliding block 2, and welding machine 5 is installed on the sliding frame 4, and welding machine 5 is in contact with support frame 3, is used for carrying out joint to cable tube port, sliding frame 4 and two A return spring 6 is provided between the sliding blocks 2, and a support mechanism 7 is provided on ...

Embodiment 2

[0075] On the basis of Example 1, such as figure 1 , figure 2 , Figure 9 with Figure 10 Shown, also comprise rotating mechanism 9, and rotating mechanism 9 includes mounting bracket 91, biaxial motor 92, rotating shaft 93, pinion 94, rotating ring 95, bull gear 96 and connecting block 97, base 71 right side middle parts are provided with Mounting frame 91 is arranged, and biaxial motor 92 is installed on the top of mounting frame 91, and rotating shaft 93 is all arranged on the both sides output shafts of biaxial motor 92, and pinion 94 is all arranged on two rotating shafts 93, two support rings 1. The outer sides are both rotatable and are provided with a rotating ring 95. The outer sides of the two rotating rings 95 are equipped with a large gear 96. The two small gears 94 are meshed with the large gear 96 on the same side. The right sides of the two rotating rings 95 are equipped with connecting Block 97, two connecting blocks 97 are in contact with the sliding block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com