POE (Polyolefin Elastomer) calendering material for X-ray and gamma-ray protection and preparation method thereof

A technology of calendering materials and γ-rays, applied in the field of X-rays, can solve the problems of low-energy X-rays with large scattering, toxicity, and poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

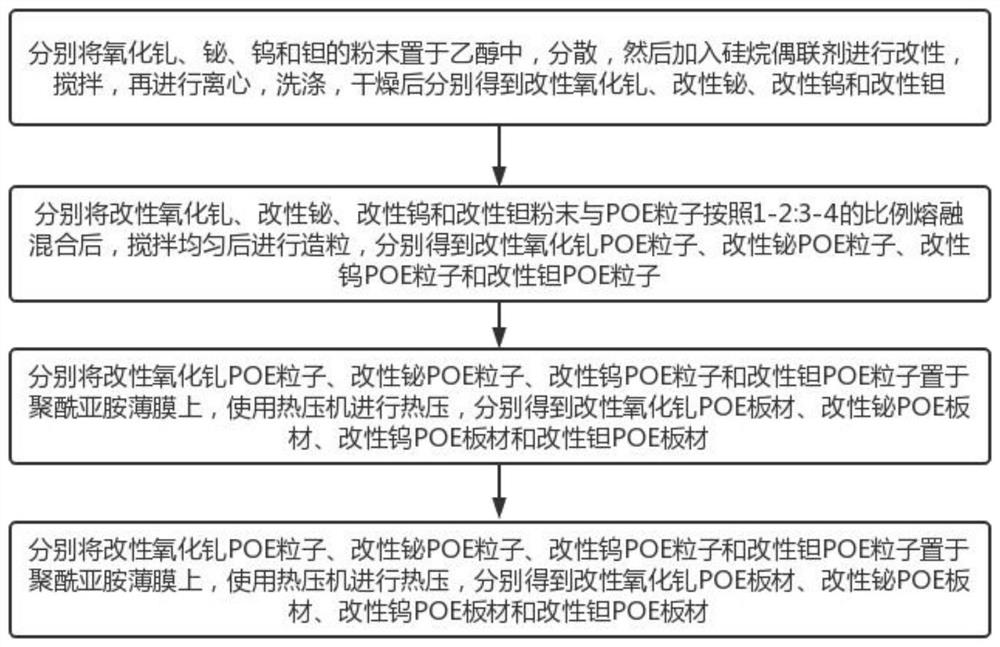

[0035] A preparation process of POE layered calendering material for X, gamma ray protection, comprising the following steps:

[0036] Modification: The powders of gadolinium oxide, bismuth, tungsten and tantalum with a particle size of 50 nm were placed in ethanol, and ultrasonically dispersed for 10 min. After that, octaaminophenyltrioxysilane was added, and magnetic stirring was conducted for 18 h. Centrifugation at a high speed, followed by washing twice with absolute ethanol, and then drying at 60 °C for 16 h to obtain modified gadolinium oxide, modified bismuth, modified tungsten and modified tantalum powders respectively;

[0037] Granulation: After the modified gadolinium oxide, modified bismuth, modified tungsten and modified tantalum powders and POE particles were melt-mixed in a ratio of 3:2, melt-mixed at 60 °C, and granulated after mechanical stirring for 2 hours. , respectively obtain modified gadolinium oxide POE particles, modified bismuth POE particles, modifi...

Embodiment 2

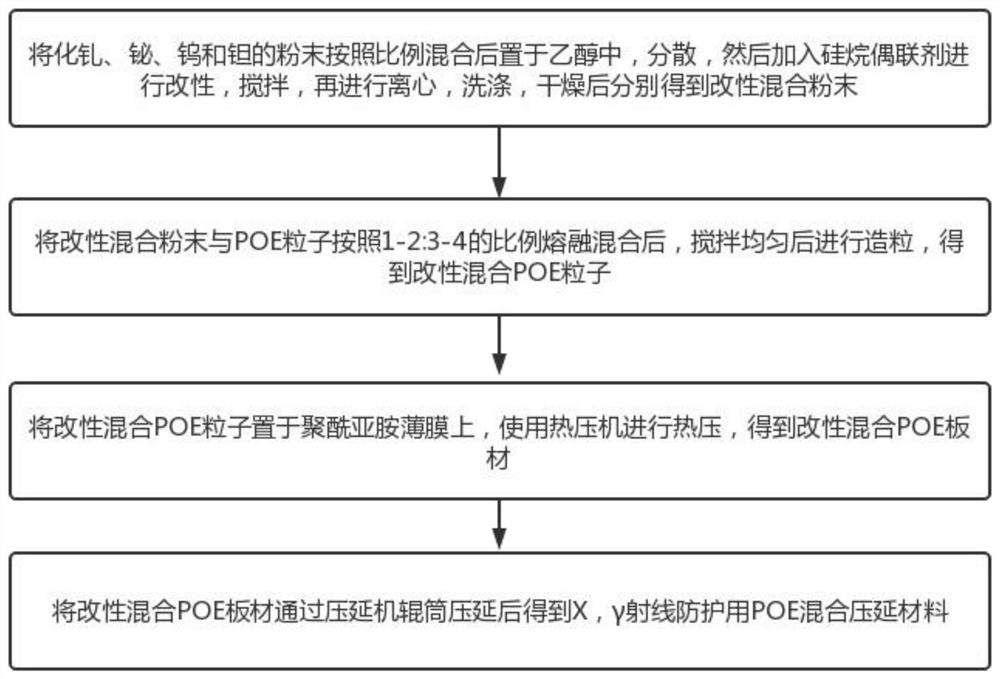

[0041] A preparation process of POE layered calendering material for X, gamma ray protection, comprising the following steps:

[0042] Modification: The powders of gadolinium oxide, bismuth, tungsten and tantalum with a particle size of 70nm were placed in ethanol, ultrasonically dispersed for 15min, then added octaaminophenyltrioxysilane, and magnetically stirred for 20h, and then at 9000r / min After centrifugation at a high speed, washed with absolute ethanol for 3 times, and then dried at 65 °C for 14 h to obtain modified gadolinium oxide, modified bismuth, modified tungsten and modified tantalum powders respectively;

[0043] Granulation: After the modified gadolinium oxide, modified bismuth, modified tungsten and modified tantalum powders and POE particles were melt-mixed in a ratio of 7:3, melt-mixed at 70 °C, and granulated after mechanical stirring for 3 hours. , respectively obtain modified gadolinium oxide POE particles, modified bismuth POE particles, modified tungst...

Embodiment 3

[0047] A preparation process of POE layered calendering material for X, gamma ray protection, comprising the following steps:

[0048] Modification: The powders of gadolinium oxide, bismuth, tungsten and tantalum with a particle size of 100 nm were respectively placed in ethanol, and ultrasonically dispersed for 20 min. After that, octaaminophenyltrioxysilane was added, and magnetic stirring was conducted for 24 h. The centrifugation was carried out at a speed of 100 °C, followed by washing twice with absolute ethanol, and then drying at 70 °C for 12 h to obtain modified gadolinium oxide, modified bismuth, modified tungsten and modified tantalum powders respectively;

[0049] Granulation: After the modified gadolinium oxide, modified bismuth, modified tungsten and modified tantalum powders and POE particles were melt-mixed in a ratio of 4:1, melt-mixed at 80 °C, and granulated after mechanical stirring for 4 hours , respectively obtain modified gadolinium oxide POE particles, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com