Packaging adhesive film

A technology of encapsulation film and transparent encapsulant, which is applied in the direction of adhesive, film/sheet without carrier, film/sheet adhesive, etc., can solve the problem of high hardness of the encapsulation film, and reduce the density and hardness. , Conducive to the effect of lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

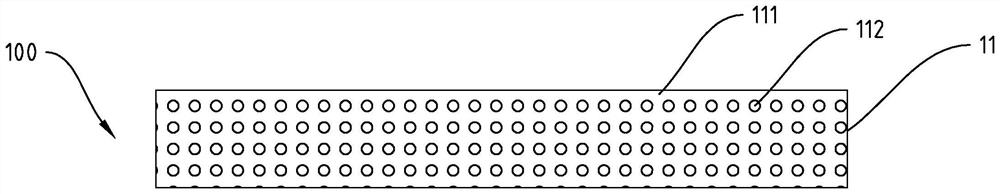

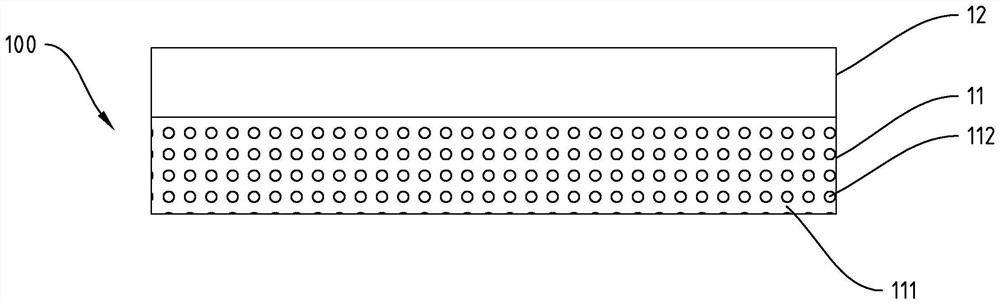

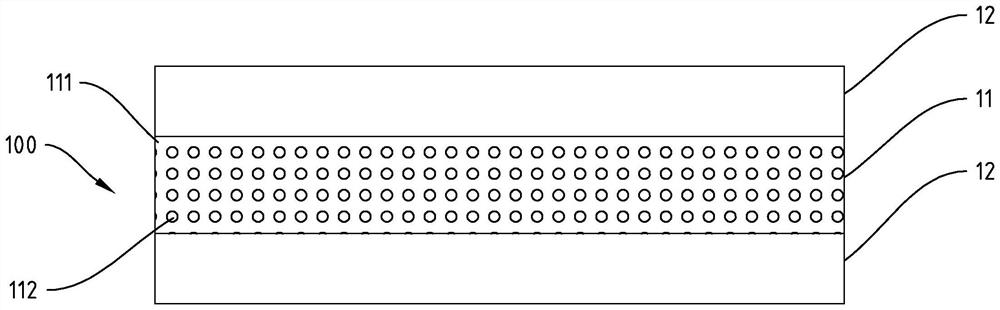

[0053] As shown in FIG. 1, an encapsulation film 100, specifically a transparent encapsulation film, is only composed of a cell layer 11. Cells

Embodiment 2

[0055] As shown in FIG. 1, an encapsulation film 100 is specifically a transparent encapsulation film. In addition to the encapsulation film prepared

Embodiment 3

[0057] As shown in FIG. 1, an encapsulation film 100 is specifically a transparent encapsulation film. The foamed layer is the same as in Example 1, but

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com