High-bearing-capacity integrally-formed composite material joint and manufacturing method

A technology of integral molding and manufacturing method, which is applied in the direction of building structure, construction, bridge construction, etc., can solve the problems of low bearing capacity of the connection method and complicated manufacturing process, and achieve convenient molding process, good fatigue performance and high connection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

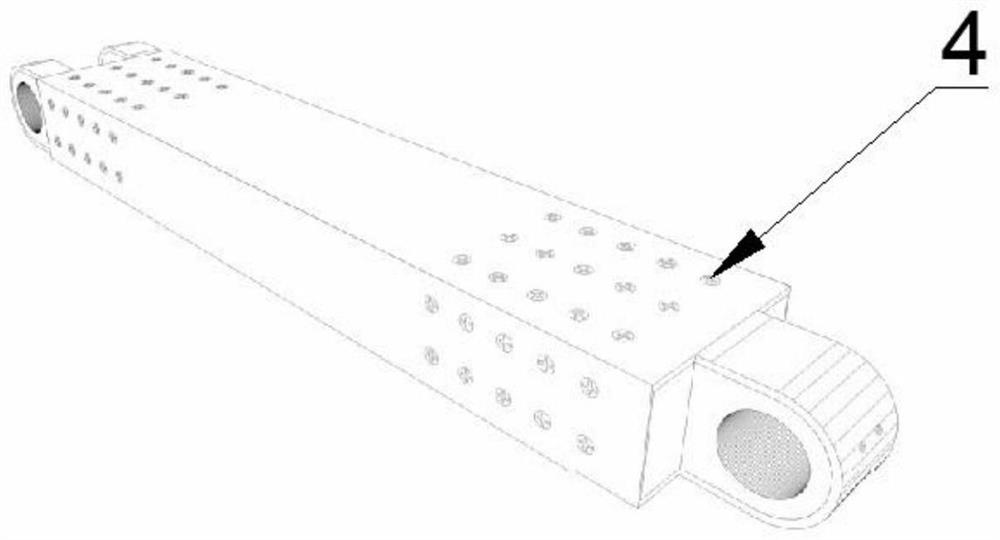

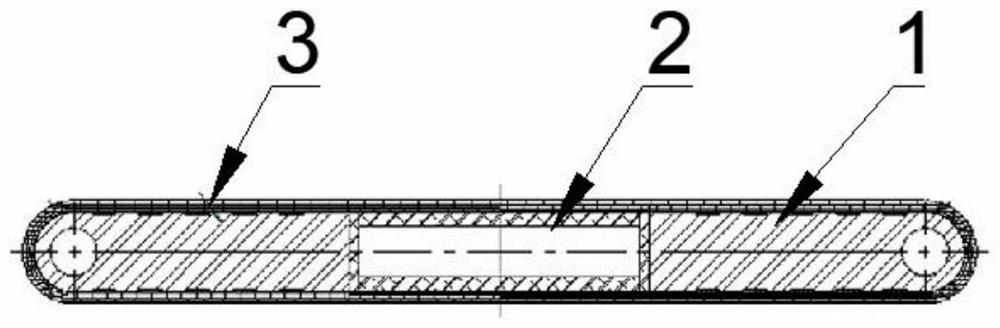

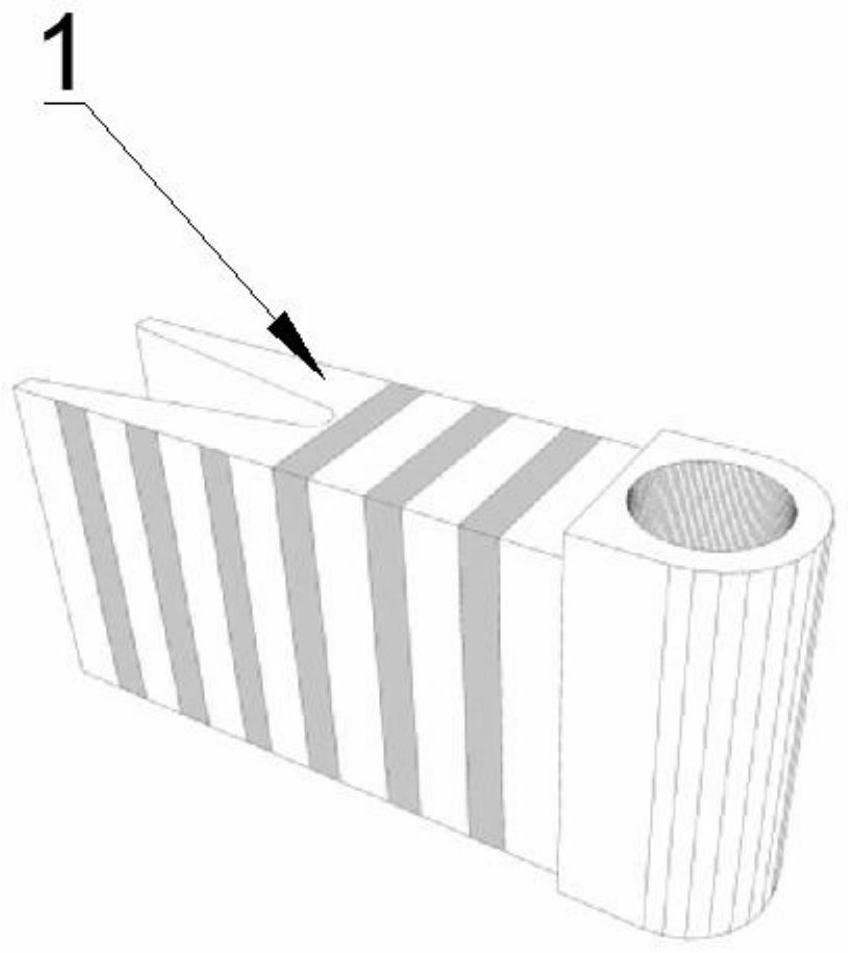

[0033] Such as figure 1 and figure 2 As shown, the present embodiment provides a high bearing capacity integrally formed composite material joint, comprising a metal inner core 1, a middle balsa wood core layer 2, and an outer winding layer 3. A metal inner core 1 is respectively provided at both ends of the joint, and at the same time The two metal inner cores 1 and the middle balsa wood core layer 2 are connected by glue bonding, and the outer winding layer 3 is arranged on the assembled surface of the metal inner core 1 and the middle balsa wood core layer 2, and the outer winding layer 3 includes five kinds of CFRP prepreg fabrics with different winding angles. The outer surface of the outer winding layer 3 after winding is provided with a number of bolt holes, and high-strength bolts 4 are installed in the bolt holes, that is, the outer winding layer 3 passes through the bolts and the metal inner core 1 and The middle balsa wood core layers 2 are connected to each other...

Embodiment 2

[0044] A method for manufacturing a high-bearing-capacity integrally formed composite joint. In the manufacturing method, the inner core of the joint and the externally wound CFRP are jointly stressed through the bonding force between the bolt and the surface of the structure, and finally a high-bearing-capacity integrally formed joint is obtained. , including the following steps:

[0045] Step S1: Assembling the inner core of the joint; processing the metal inner core 1 at both ends and the middle balsa wood core layer 2, bonding the metal inner core 1 at both ends and the middle balsa wood core layer 2 into one body by glue, and the metal inner core 1 and the middle The balsa wood core layer 2 is bonded and fixed, and the inner core of the joint is adjusted by the tooling to make it straight. A layer of fiber felt, after curing, polish the surface, and polish the four corners of the inner line of the joint;

[0046] Step S2: Wrap CFRP prepreg; Wrap CFRP prepreg layer by lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com