Scum cleaning and conveying system for arc-shaped bottom surface of tunnel

A curved bottom surface and scum technology, which is applied in the field of tunnel cleaning, can solve the problems of affecting the normal passage space of battery vehicles, uneven curved bottom surface, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

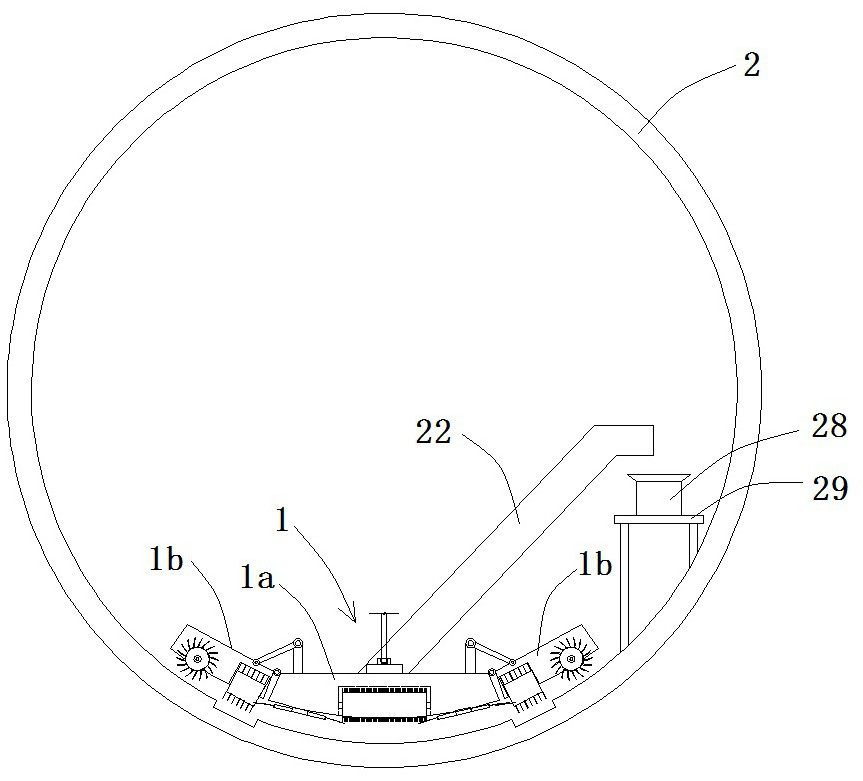

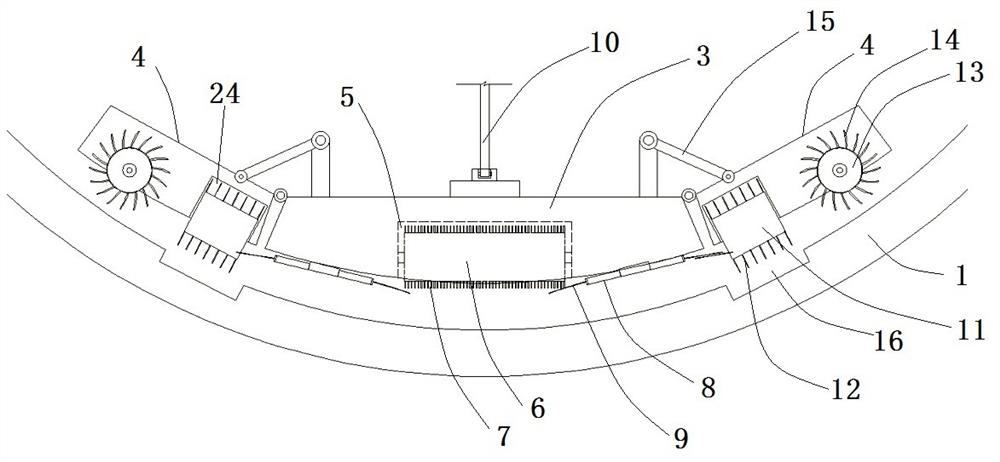

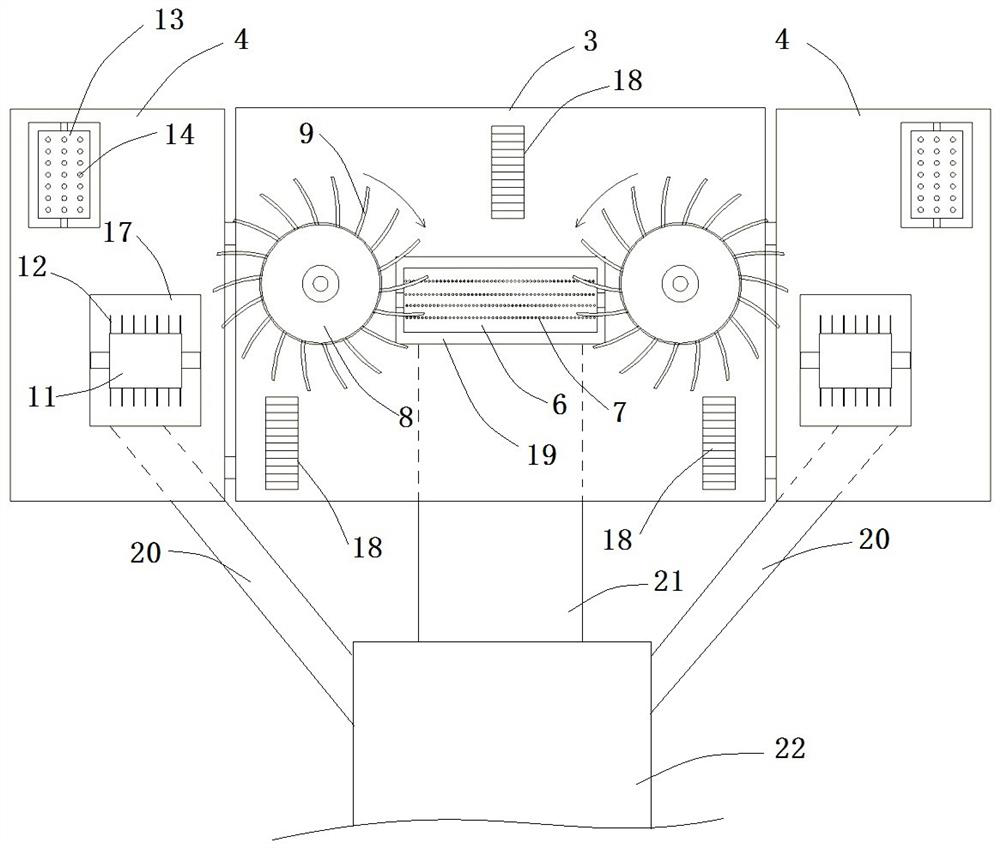

[0030] Example: such as Figure 1-7 As shown, this embodiment specifically relates to a scum cleaning and transportation system used on the arc-shaped bottom of a tunnel. The scum cleaning and transportation system 1 is arranged on the arc-shaped bottom of the tunnel 2. The shield tunnel 2 is formed by The structural segments are assembled in the circumferential and longitudinal directions, so there are a number of bolt holes 16 distributed at intervals on the arc-shaped bottom surface. The scum cleaning and conveying system mainly includes the middle cleaning machine 1a set in the center and the middle cleaning machine 1a hingedly arranged The side cleaning machines 1b on both sides, under the angle adjustment control of the angle adjustment mechanism 15, the side cleaning machines 1b are adapted to the arc-shaped bottom surface of the tunnel 2 and the interval distribution of the bolt holes 16, so as to realize the automatic and efficient removal of scum in the tunnel 2 Clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com