Connecting and supporting structure of multifunctional hydraulic control system

A hydraulic control system and support structure technology, applied in wind power generation, components with teeth, transmission devices, etc., can solve the problems of sharply increased development costs and longer design and development cycles, and achieve improved energy transfer efficiency and fixed connections and the effect of simple assembly process and increased usable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

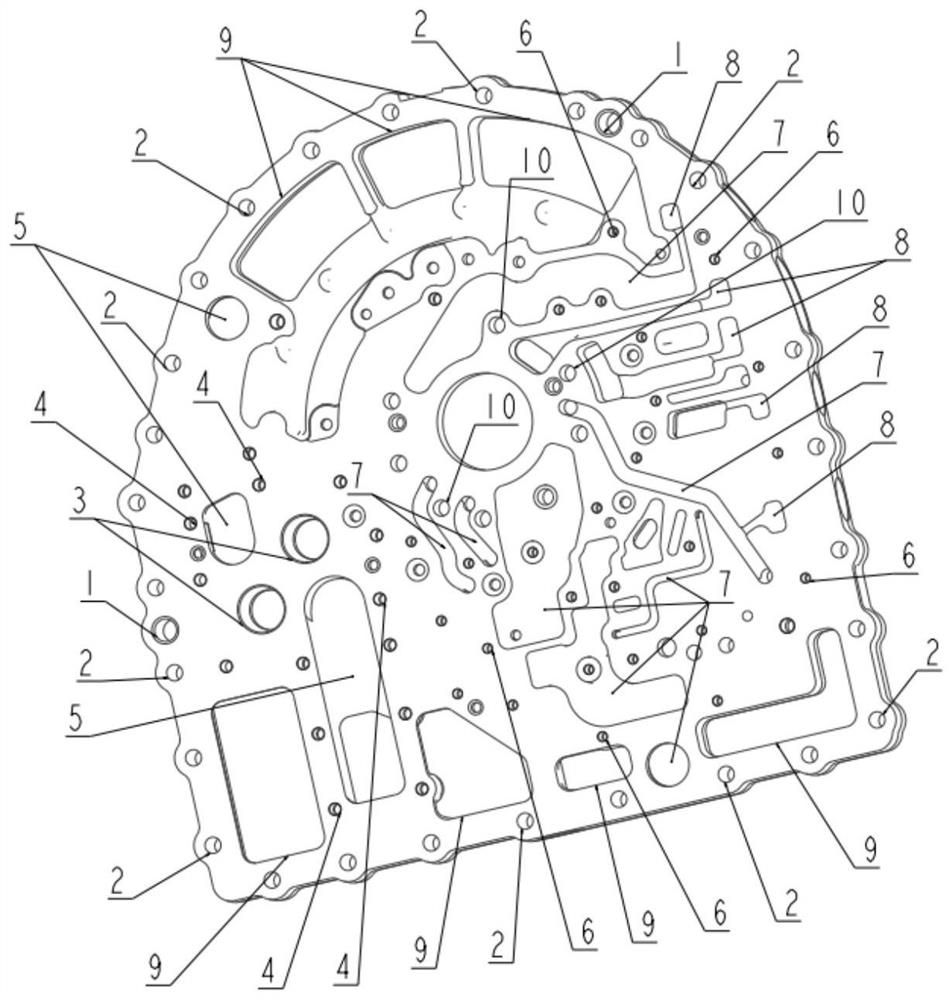

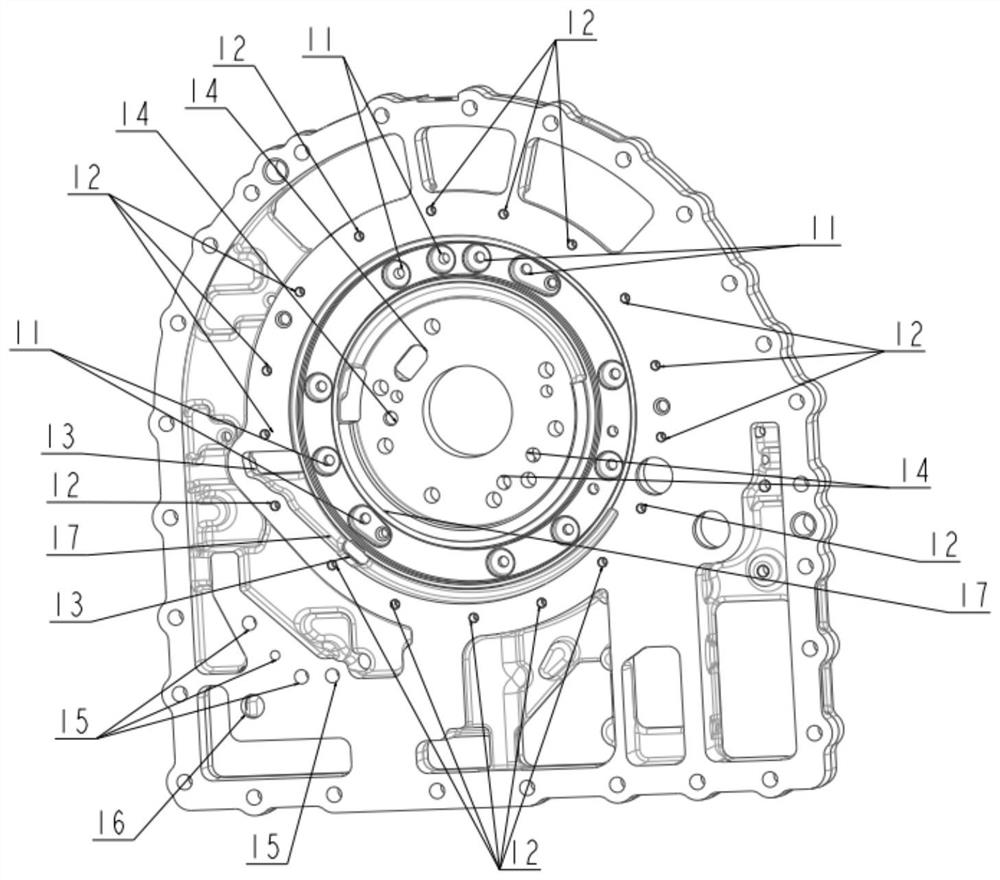

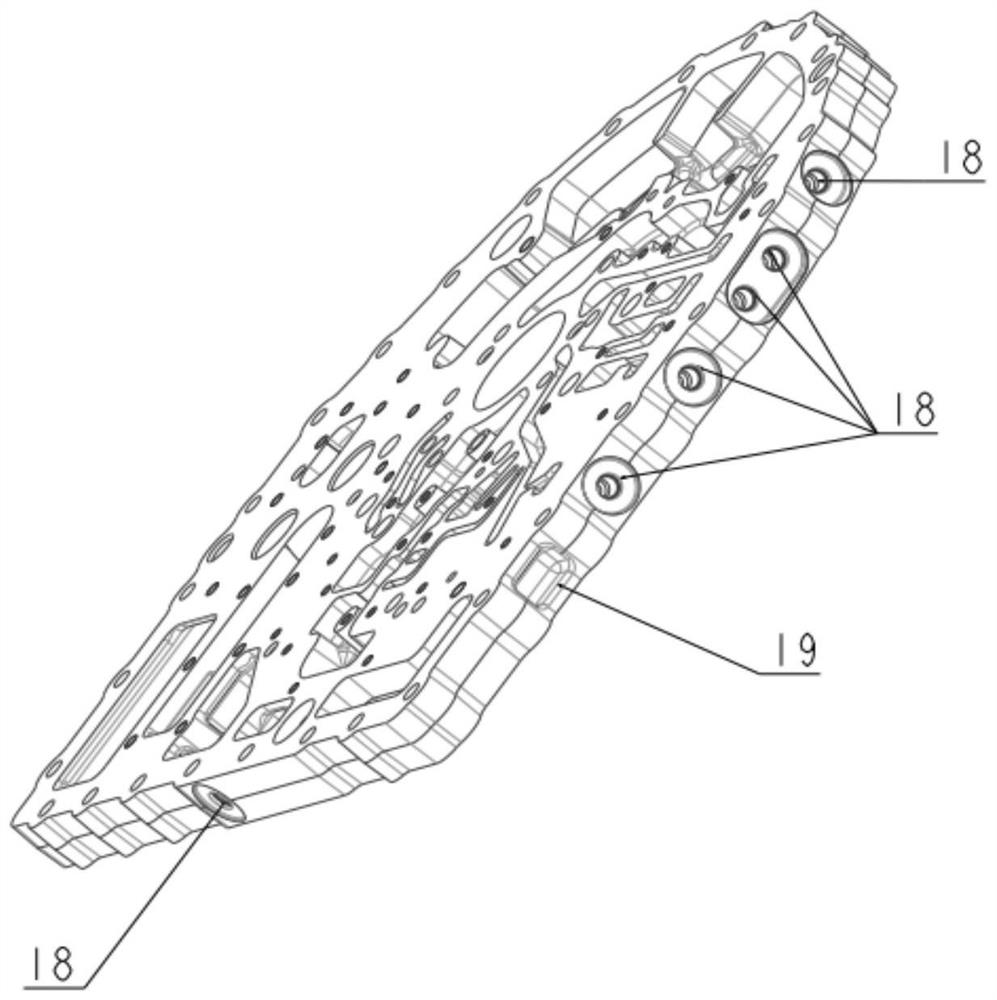

[0037] see Figure 1 to Figure 6 , the features required on the hydraulic system connection support structure are all machined according to the specific size requirements, and the four positioning pins 21 are respectively installed on the two sides of the connection support device to the two sides of the connection support structure. In the fixing pin hole 1 connected with the gearbox casing and the torque converter casing, ensure that the connection support structure is stably and accurately fixed to the upper end surface of the hydraulic automatic transmission casing, providing a stable foundation for the subsequent layout of different subsystems. platform. Install the sealing device 22 on the end face of the connecting support structure connecting the hydraulic control system module and the power input device of the hydraulic system to ensure that there is no misalignment between the through holes of the power medium, and ensure that the hydraulic control system module and ...

Embodiment 2

[0046] Such as Figure 7 Shown, be another kind of embodiment of the present invention, embodiment 2 is similar in structure to embodiment 1, and its difference is:

[0047]The features required for the connection support structure of the hydraulic system are all machined according to the specific size requirements, and 11 through holes for fasteners connected to the fixing parts of the hydraulic deceleration system can be omitted. The machining steps of the fastener threaded holes 12 of the shell and the three through holes 13 of the power medium channel connecting the hydraulic deceleration system device reduce the machining process, improve the production efficiency of the parts, and reduce a certain cost.

[0048] Then follow the steps of Embodiment 1 to assemble to the hydraulic torque converter guide wheel seat 29 and the power medium distribution device 28, and the hydraulic deceleration system device 27 and its accessories are no longer used in this embodiment. At thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com