Digital camouflage spraying device and method

A technology of spraying device and camouflage, applied in the direction of spraying device, etc., can solve problems such as inability to guarantee spraying effect, uneven spraying surface, non-reproducibility, etc., achieve repeatability and accuracy, good blocking effect, and prevent volatilization. and wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

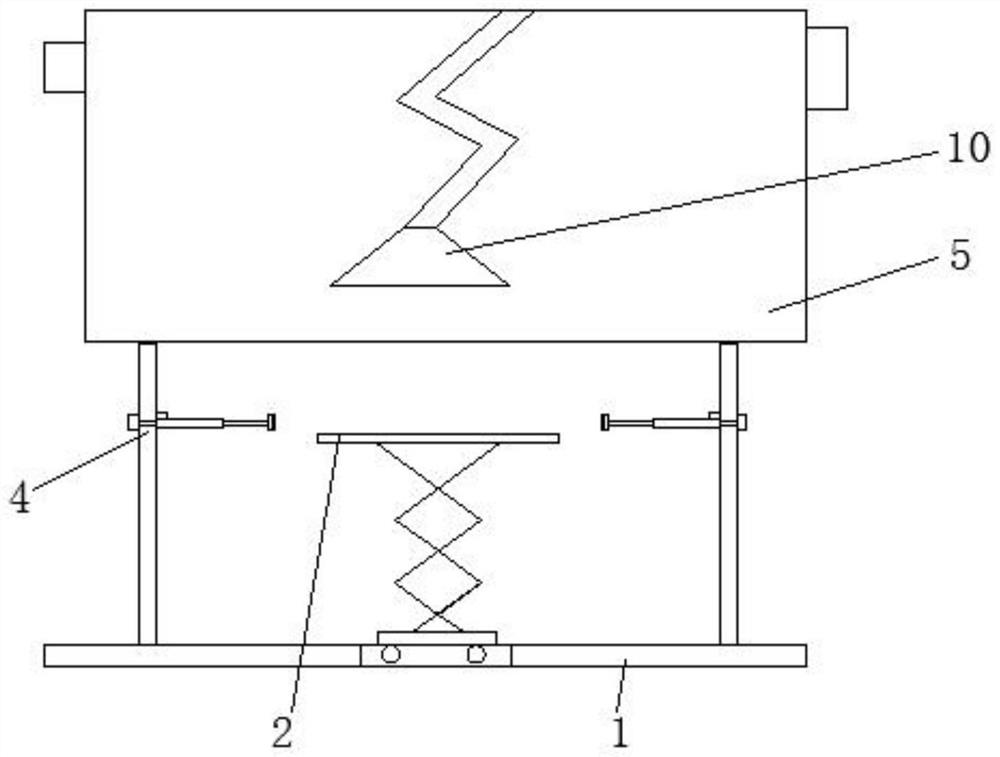

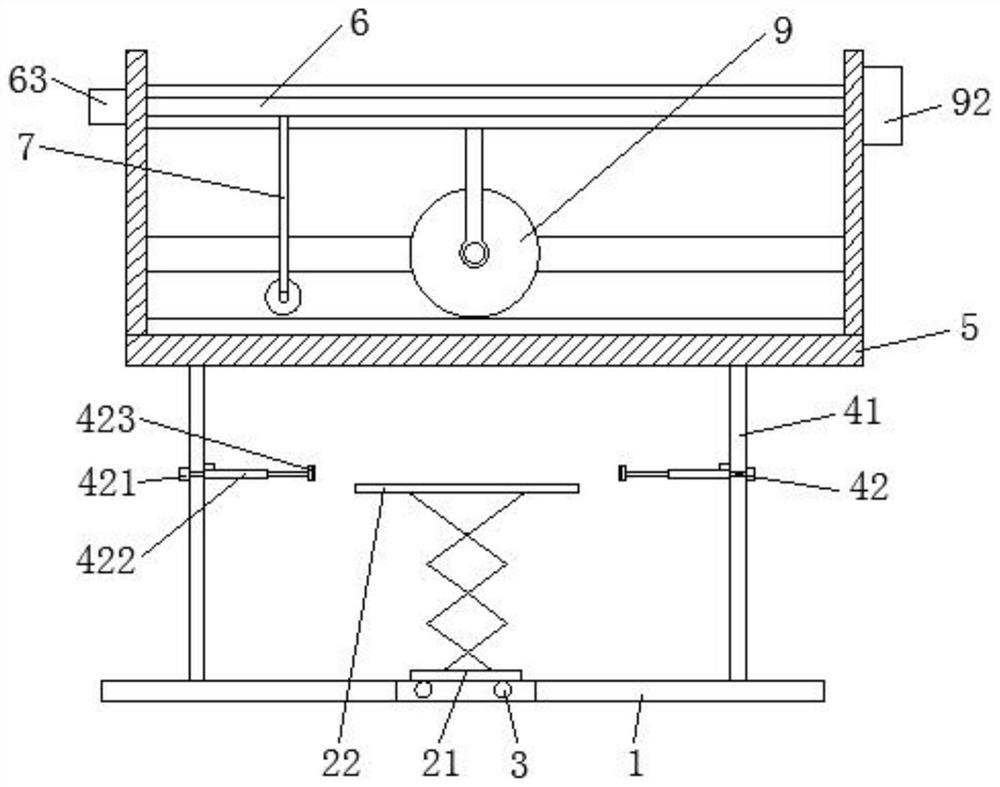

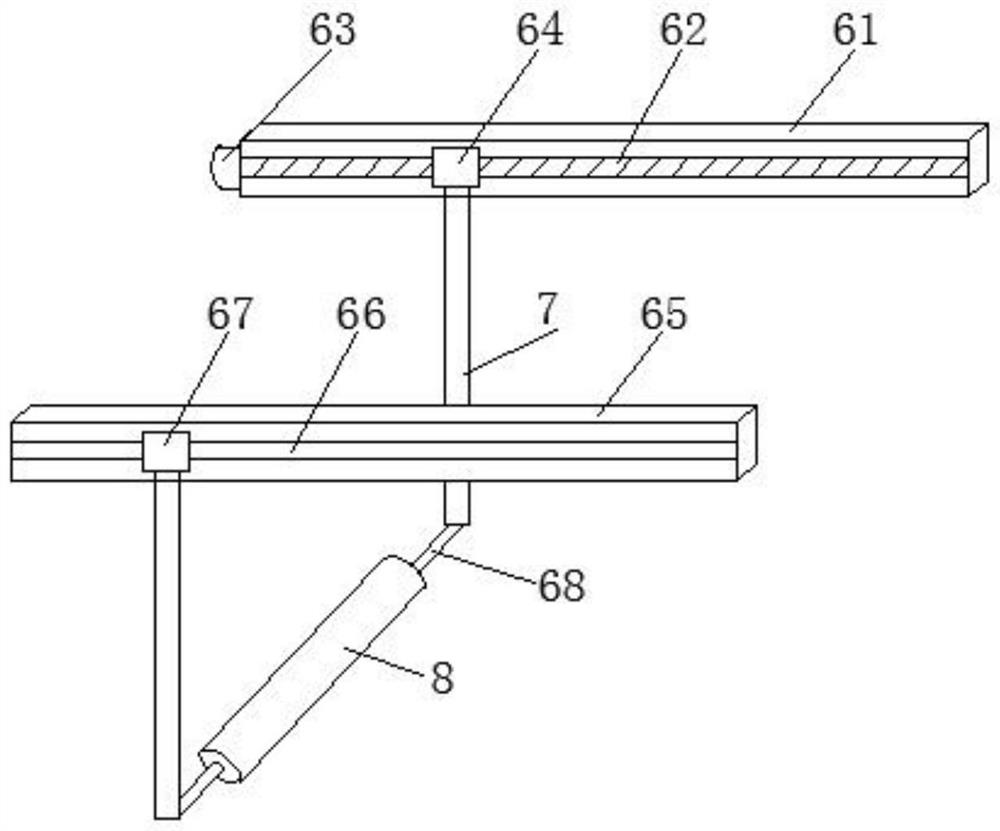

[0064] The invention provides a digital camouflage spraying device, specifically as follows Figure 1 to Figure 6 As shown, it includes a base 1, a lifting support frame 2, two sets of clamping assemblies 4, a box body 5, a film sticking assembly, a laminating assembly 9 and a spraying assembly 10. In this embodiment, a control system is also set to automatically control the entire device, The control modules of each component are electrically connected with the control system. The base 1 plays a supporting role. The lifting support frame 2 supports and adjusts the height of the spraying board. The clamping component 4 performs the flip operation on the spraying board. The digital camouflage grid paper on the spraying board is flattened and pressed, and the spraying component 10 is used to color the spraying board.

[0065] Further, in this embodiment, the lifting support frame 2 includes a hydraulic lifting platform 21 and a support plate 22 . The bottom of the hydraulic li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com