Hydraulic pipeline assembly device and assembly welding process

A technology of hydraulic pipelines and welding processes, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve problems affecting the quality of online products and technological transformation progress, low efficiency of welding methods, dependence on weld quality, etc., to achieve material acquisition and production Convenience, reliable and stable welding quality, and short working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

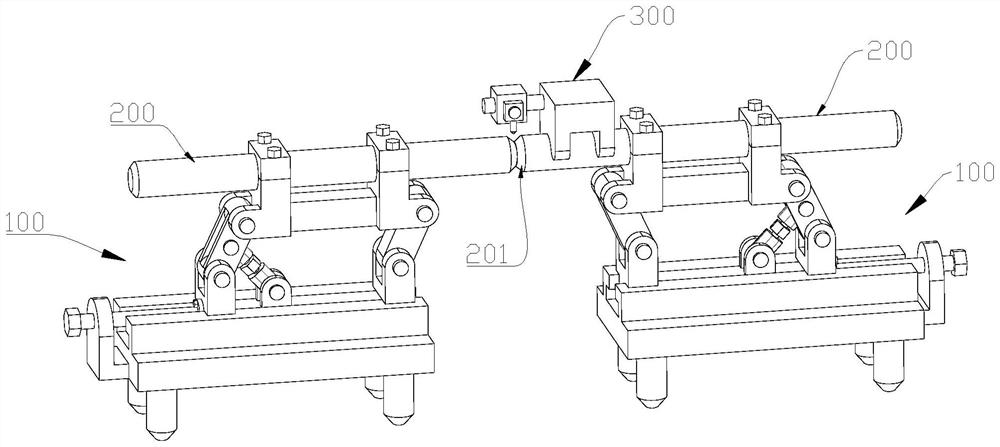

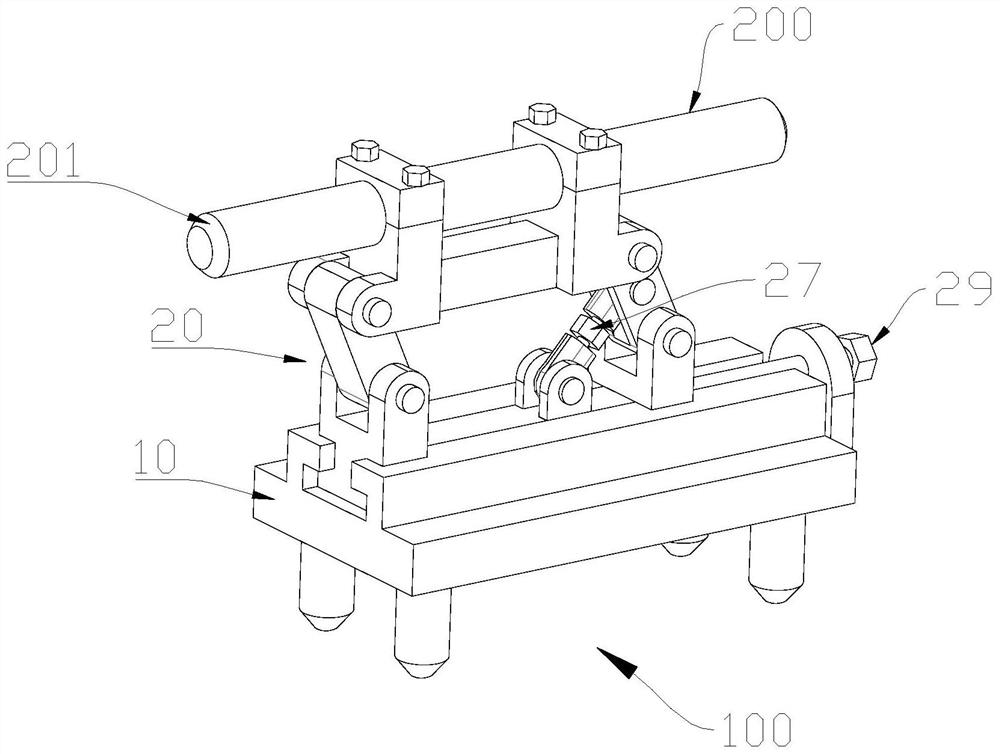

Embodiment 1

[0037] like Figure 1-Figure 5As shown, a hydraulic pipeline pairing device of the present invention is used for the pairing of the grooves 201 opened by the corresponding nozzles of the two sections of the hydraulic pipeline 200, so as to facilitate the welding of the two sections of the hydraulic pipeline 200, and it includes at least two pairings The tooling unit 100, each pair of tooling units 100 includes a fixed base 10 and a movable link mechanism 20, the top of the fixed base 10 is provided with a chute 11; the movable link mechanism 20 includes a sliding arrangement in the chute 11 The sliding seat 21 is provided with a sliding seat adjusting mechanism 29 between one end of the sliding seat 21 and the fixed base 10, and a first connecting rod 22 and a second connecting rod 23 are respectively connected on both sides of the top of the sliding seat 21 through pins 25, The first connecting rod 22 and the second connecting rod 23 have the same specifications, and a bidire...

Embodiment 2

[0044] like Figure 1-Figure 7 As shown in the figure, a hydraulic pipeline group butt welding process of the present invention is used for the group butt welding of the ends of two hydraulic pipelines 200. Taking the hydraulic pipeline 200 with a diameter of 76 mm as an example, the corresponding ends of the two hydraulic pipelines 200 are firstly provided with grooves. After 201, use the hydraulic pipeline grouping device described in Embodiment 1 to group the grooves 201 of the two sections of the hydraulic pipeline 200. First, set the two groups to the tooling units 100 at corresponding intervals to ensure that they are on the same horizontal line. , and then fix the two sections of hydraulic pipelines 200 on the tops of the two pairs of tooling units 100 through the pipeline locking mechanism respectively, and then preliminarily adjust the distance between the two sections of hydraulic pipelines 200 through the sliding seat adjustment mechanism 29, and then through the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com