Laser pump raw water cooling plate seamless welding equipment and welding method

A seamless welding and water-cooled plate technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of water-cooled plate adaptability adjustment, high investment cost, poor versatility, etc., to achieve strong versatility, easy operation, Effect of preventing thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

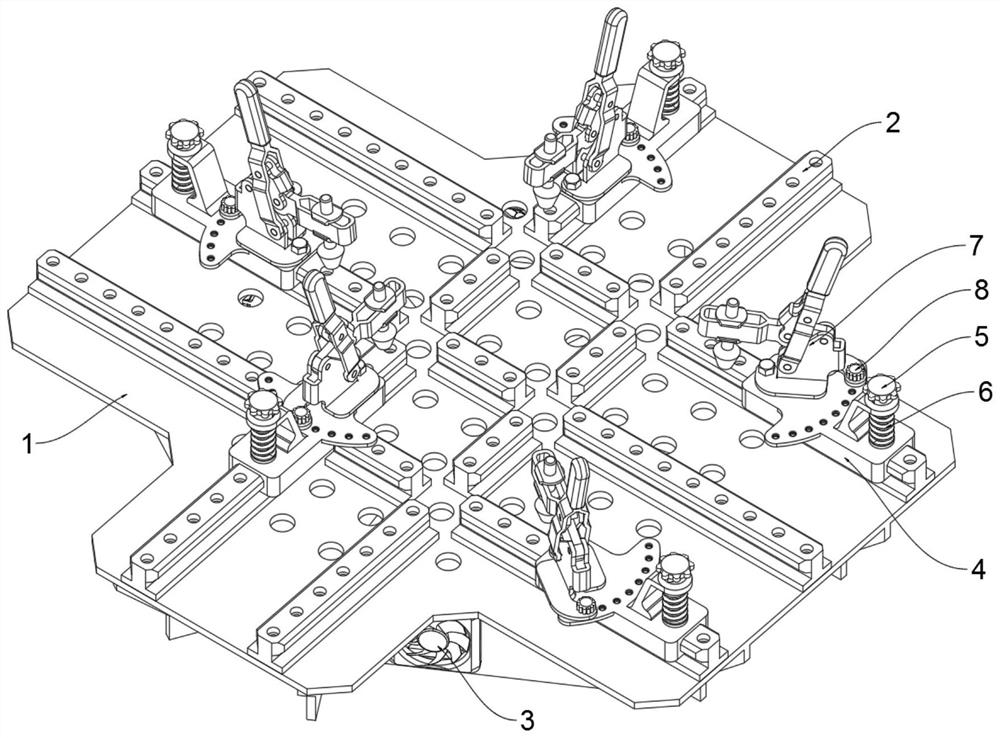

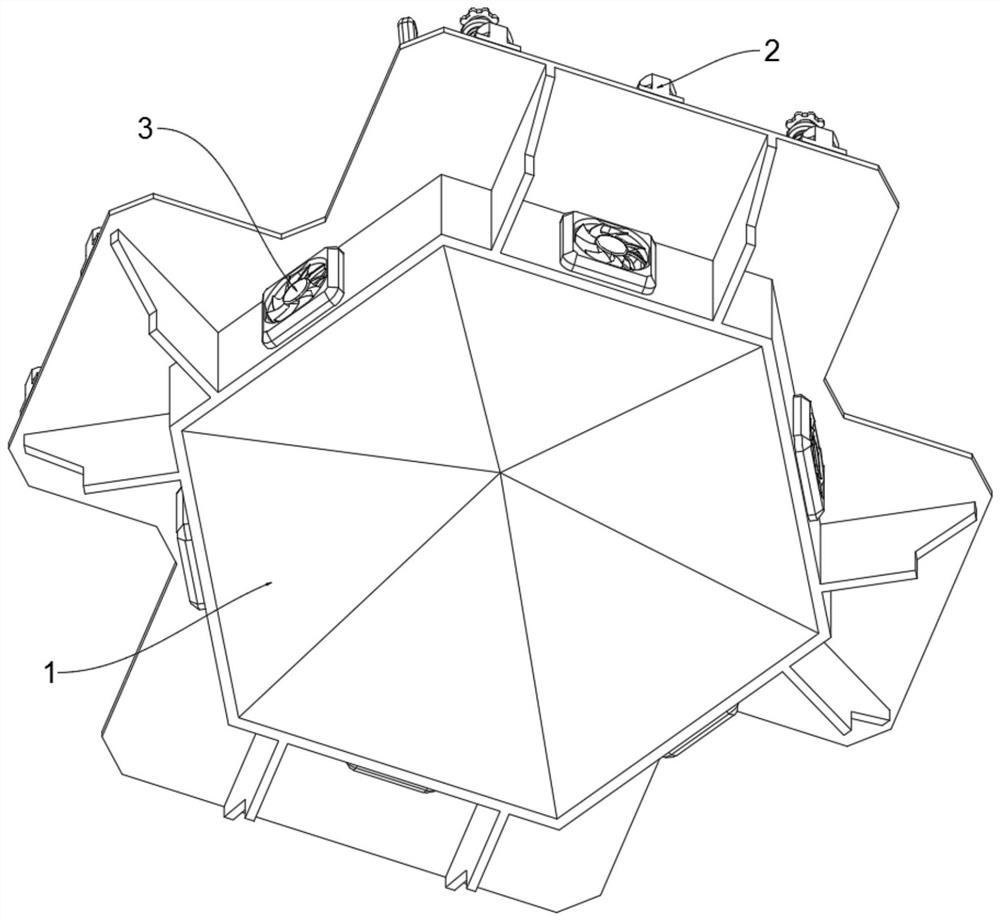

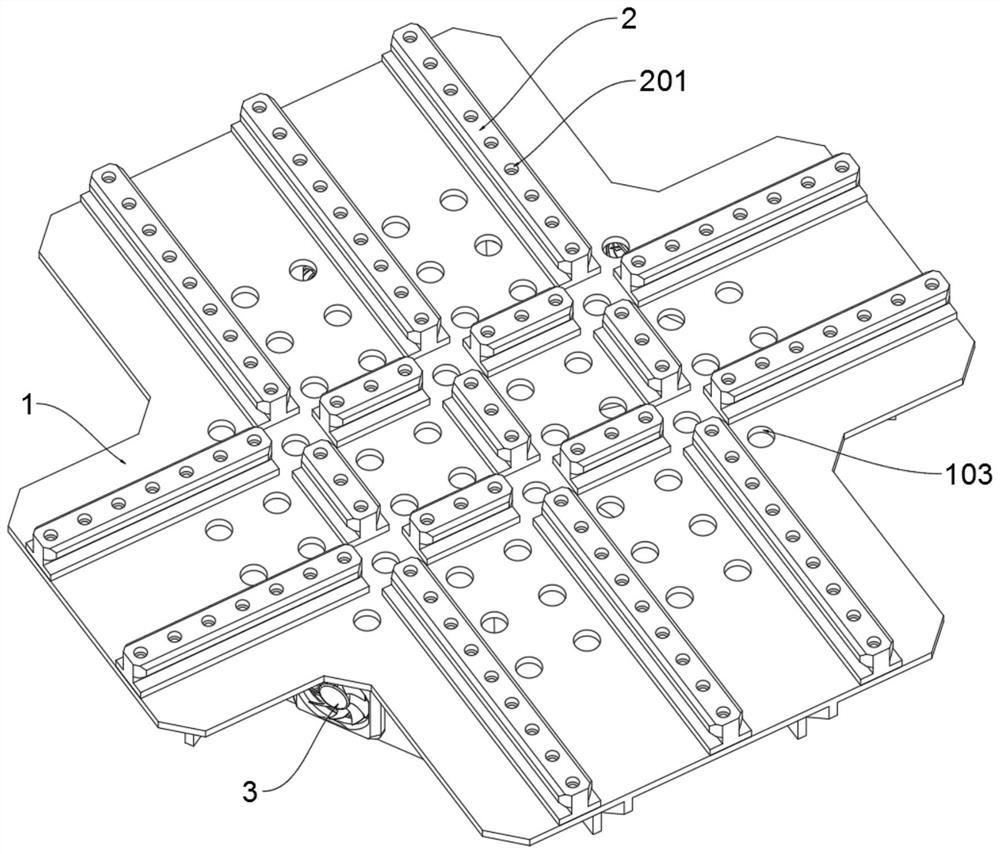

[0032] Please refer to Figure 1 to Figure 8 :

[0033] The invention proposes a seamless welding equipment and a welding method for a raw water-cooled plate of a laser pump, comprising: a welding platform 1; a slide rail 2 is installed on the top of the welding platform 1, and the slide rails 2 are arranged at seventeen places in total, and the slide rails 2 are connected to The slide rails 2 are spaced apart, and the rail seat 4 is connected to the slide rail 2; the slide rail 2 is divided into two types, long and short, the long slide rail 2 is installed vertically and horizontally on the top four ends of the welding platform 1, and the short slide rail 2 is installed in the top center of the welding platform 1 in a vertical and horizontal shape, the long slide rail 2 is aligned with the short slide rail 2, the bottom of the rail seat 4 is provided with a chute 401, and the rail seat 4 is slidably connected to the slide rail 2 through the chute 401 , according to the requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com