Garbage packing device, cleaning equipment and packing method

A garbage and garbage bag technology, which is applied in the field of garbage packaging devices, can solve the problems of easy failure of garbage bag packaging, etc., and achieve the effect of solving the problem of easy failure of garbage bag packaging, sufficient opening, and guaranteed success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0128] The present invention further provides a cleaning apparatus, comprising a rack, a cleaning device and any of the garbage packing devices in Example 1, a cleaning device and a body 100 installed in the rack, a cleaning device for cleaning garbage through the garbage input port 102 into the garbage bag. The use of the above garbage packing device provides greater convenience for garbage bag packing, improves the success rate of garbage bag packing, and avoids waste of garbage bags.

[0129] Among them, the cleaning equipment can be a cleaning robot or a vacuum cleaner.

Embodiment 3

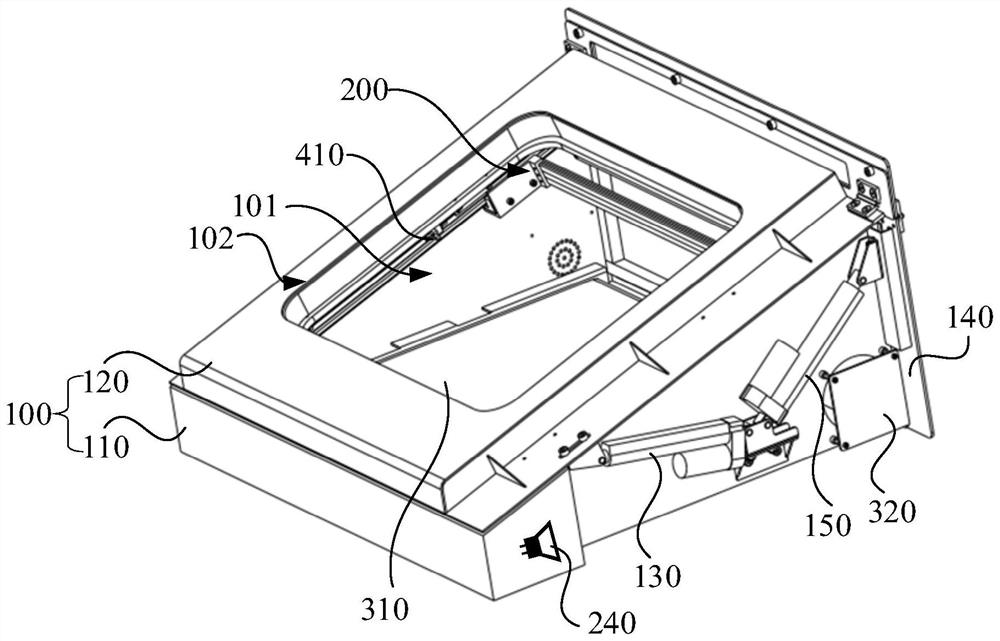

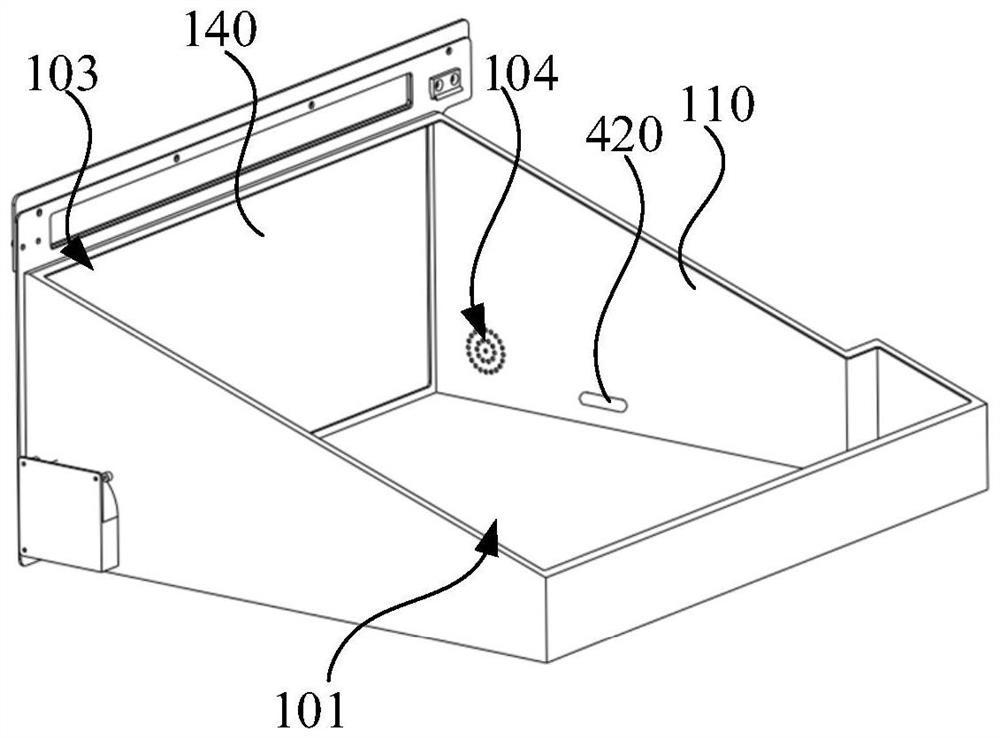

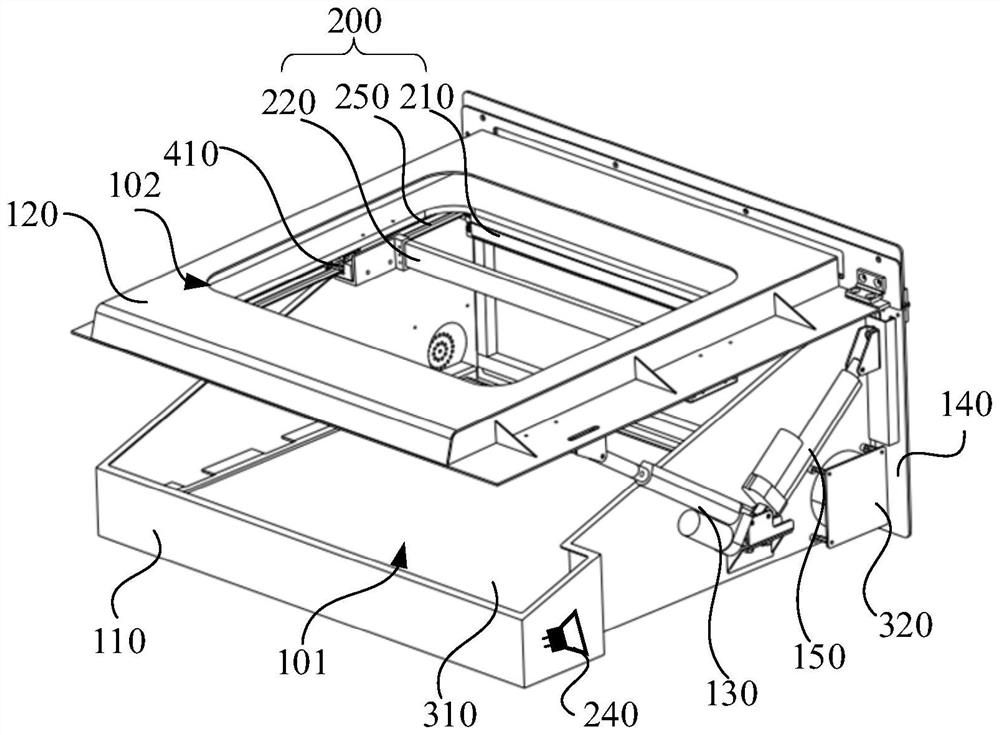

[0131] The present invention also provides a packaging method, applied to the garbage packing device, please refer to Figure 1 and Figure 2 , the garbage baler includes a body 100 and a packaging mechanism 200, the body 100 includes a garbage bin 110, a cover body 120 and a first drive assembly 130, the cover body 120 may be rotatably connected to the top of the garbage bin 110, the lid body 120 for the set of garbage bags, the packaging mechanism 200 for packing the garbage bags. The garbage packing device further comprises a spill detection device 410, a spill detection device 410 for detecting whether the garbage bag is overflowing.

[0132] Where, please refer to Figure 8 , the packaging method consists of the following steps:

[0133] S100: When receiving the overflow signal transmitted by the overflow detection device 410, the control of the first drive assembly 130 driving cover body 120 is rotated upwards relative to the garbage bin 110, which is convenient for the garbage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com