Loading machine equipment suitable for logistics loading and unloading

A technology of loader and equipment, applied in loading/unloading, conveyor, cleaning device and other directions, can solve the problems of small conveyor conveying distance and angle change, conveyor belt and transmission wheel slip, difficult to clean, etc., to improve the application scene , Improve cleaning efficiency, improve the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

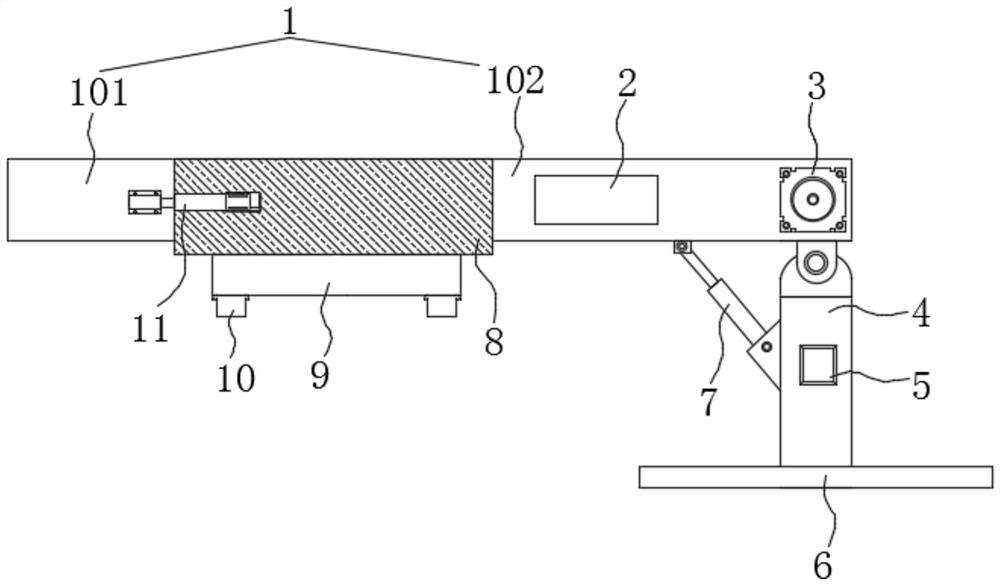

[0034] like Figure 1 to Figure 2 As shown, this embodiment is suitable for logistics loading and unloading using vehicle loader equipment, including a support column 4, a bottom plate 6 is fixed at the bottom of the support column 4, a controller 5 is installed on the front surface of the support column 4, and the top of the support column 4 passes through The angle adjustment mechanism is connected with the conveying frame 1. The conveying frame 1 includes a connecting frame 101 and a fixing frame 102. A driven roller 12 is installed inside the connecting frame 101, and a driving roller 14 is installed inside the fixing frame 102. The driven roller 12 and the driving roller A conveyor belt 16 is connected between the rollers 14 , a first motor 3 is installed on the front surface of the fixed frame 102 , and the drive shaft of the first motor 3 extends to the inside of the fixed frame 102 and is connected with the driving roller 14 , and the controller 5 makes the first motor ...

Embodiment 2

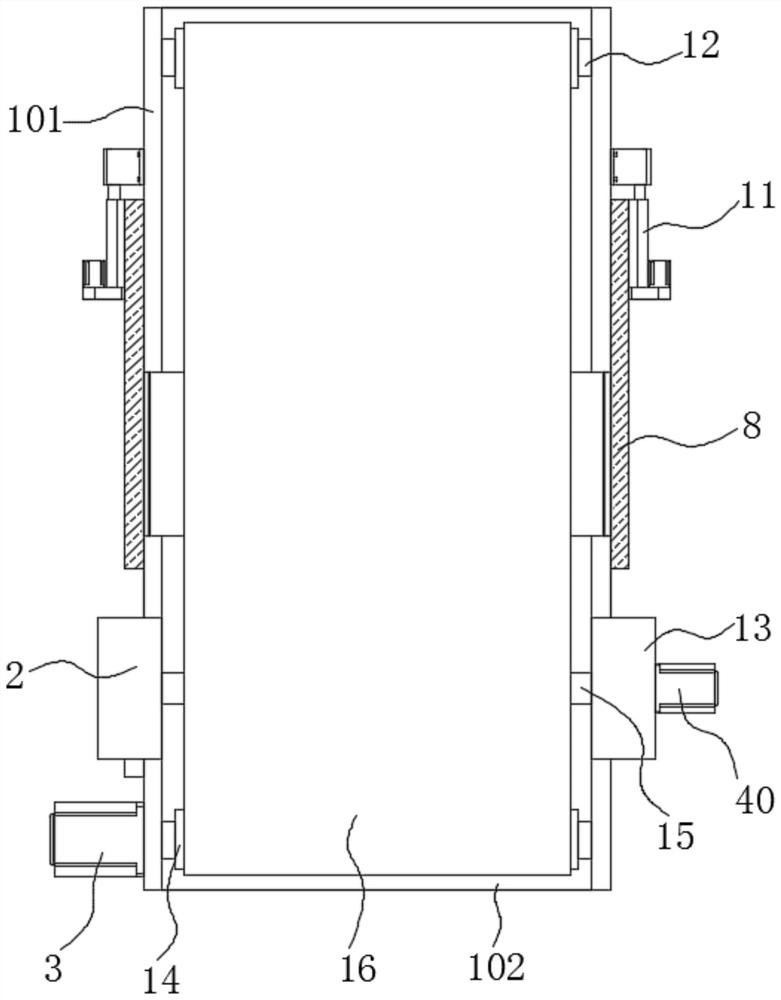

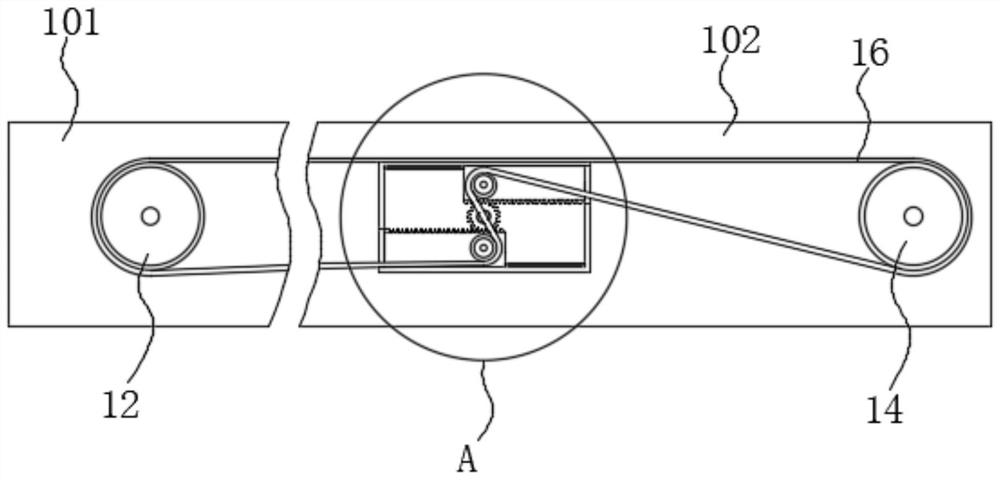

[0039] The structure of this embodiment applicable to the logistics loading and unloading equipment using a truck loader is basically the same as the structure of the first embodiment applicable to the logistics loading and unloading equipment using a truck loader. The difference lies in that a second fixing box is connected to one side of the fixing frame 102 13. A gear 20 is arranged in the middle of the second fixed box 13. The top of the gear 20 is connected with the first toothed plate 17, and the bottom of the gear 20 is connected with a second toothed plate 39. The second toothed plate 39 and the first toothed plate 17 are all slidably connected to the second fixed box 13 through the sliding rail, the fourth motor 40 is installed outside the second fixed box 13, and the transmission shaft of the fourth motor 40 extends to the inside of the second fixed box 13 and is connected with the gear 20 , the first tension roller 15 is installed on one side of the first toothed pla...

Embodiment 3

[0044] The structure of this embodiment applicable to the truck loader equipment for logistics loading and unloading is basically the same as the structure of the first and second embodiments applicable to the logistics loading and unloading truck loader equipment, the difference is that the bottom of the connection frame 8 is connected with a guide frame 9. The guide frame 9 is communicated with the interior of the connection frame 8. A support plate 38 is arranged in the middle of the inside of the guide frame 9. The inner two sides of the support plate 38 are provided with guide posts 27. The guide frame 9 is fixed, the top of the guide post 27 is fixed with a limit block, and the outer part of the guide post 27 is located between the support plate 38 and the guide frame 9 with a first spring 28 sleeved, and the middle of the top of the support plate 38 is fixed with a first spring 28 . The vertical plate 26, the top of the vertical plate 26 is installed with a brush 25, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap