Multi-section bubble assembly type anchor rod with stable pulling resistance and anchoring construction method of multi-section bubble assembly type anchor rod

A prefabricated and anchor technology, applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve the problems of not being able to determine whether the size and quality of the bubbles meet the requirements, difficult to check the quality of the anchors with multiple bubbles, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

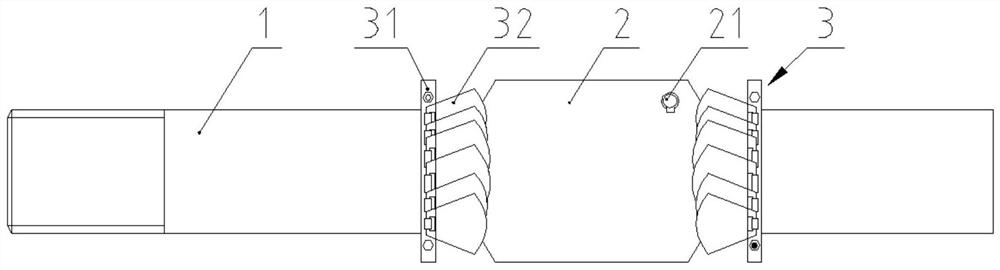

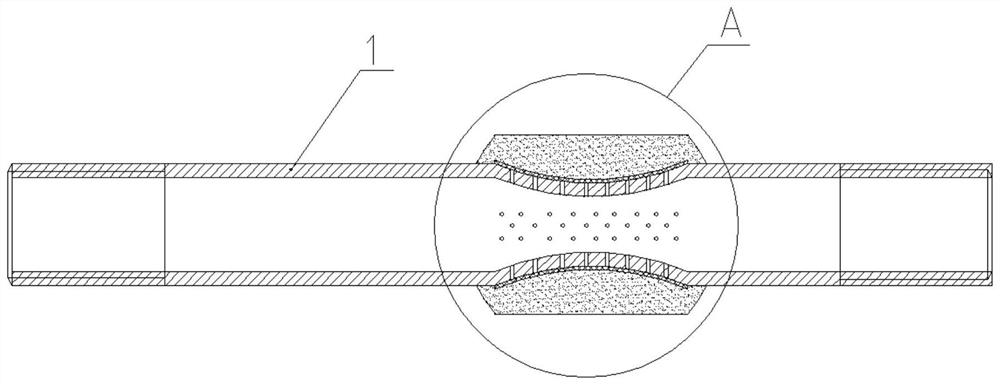

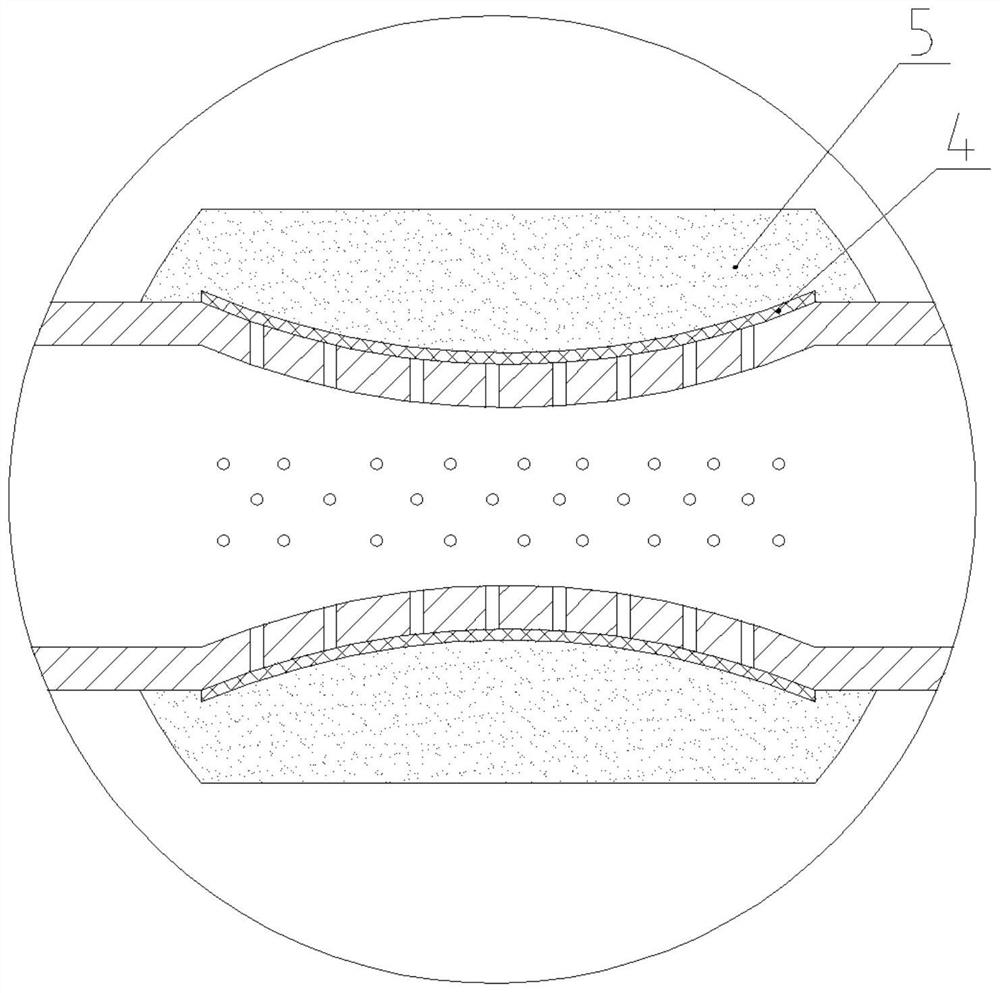

[0028] The purpose of the present invention is to overcome the defect that the multi-section foam bolt is formed by pressing and grouting: the scale of the supporting equipment is large, the operation of the pressing and grouting process is complicated, and it is difficult to check the quality of the multi-section foam bolt after grouting. The size and quality of the nodal bulbs could not be determined.

[0029] In order to achieve the above purpose, the present invention designs a multi-section foam assembled anchor rod, which adopts polyurethane composite material to expand to form section cells to realize the stable anchoring of the anchor rod. During the anchoring construction, it is only necessary to put the anchor rod into the anchor rod and the anchor rod anchoring hole. Water injection separately, the equipment is simple to match, and the anchoring operation is simple.

[0030] The bolt structure and its anchoring construction method of the present invention will be de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com