Composite fiber non-woven fabric and preparation method thereof

A technology of composite fibers and non-woven fabrics, applied in non-woven fabrics, textiles and papermaking, lighting and heating equipment, etc. Easy to replace and avoid tilting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

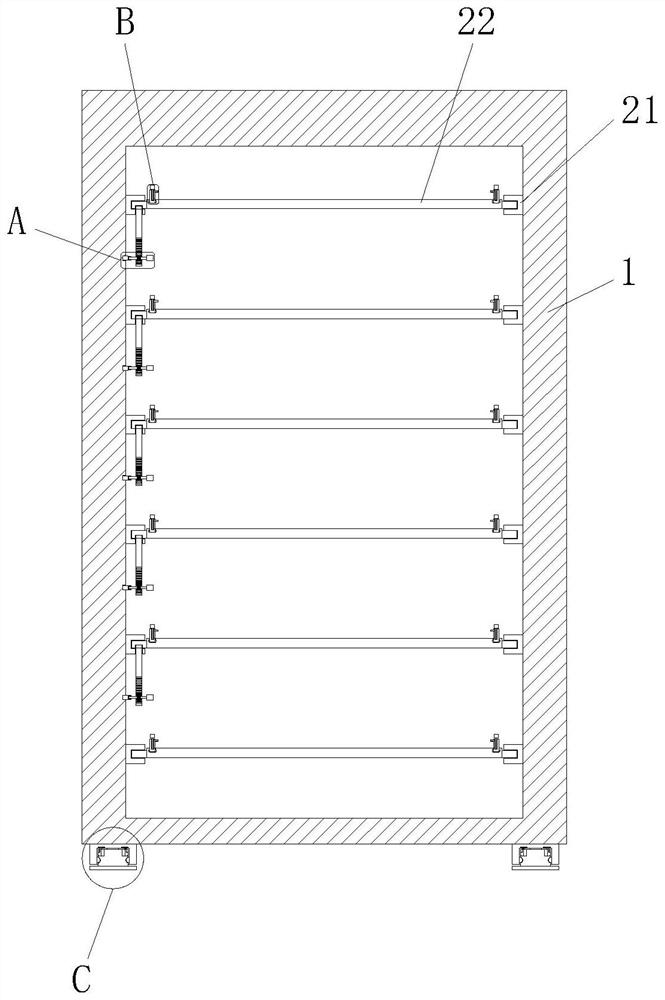

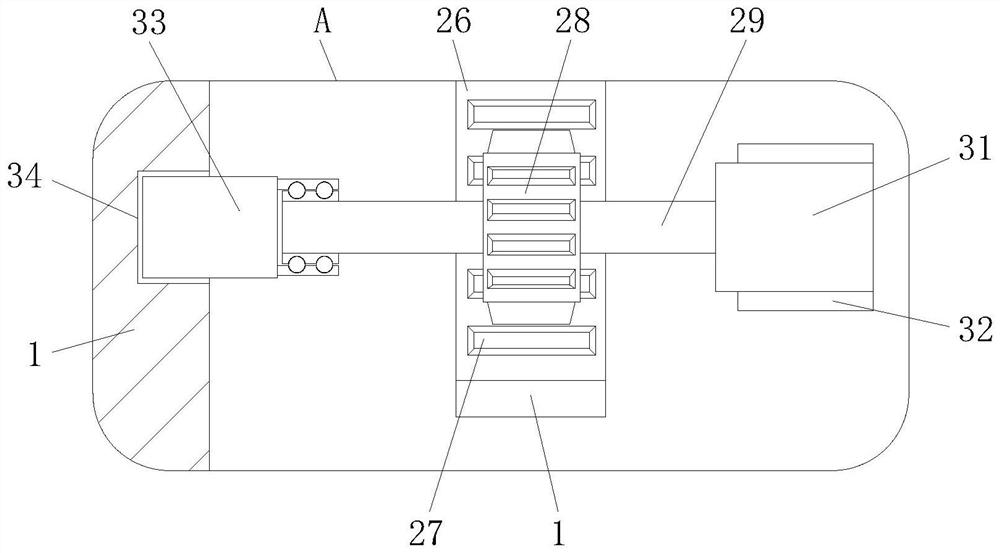

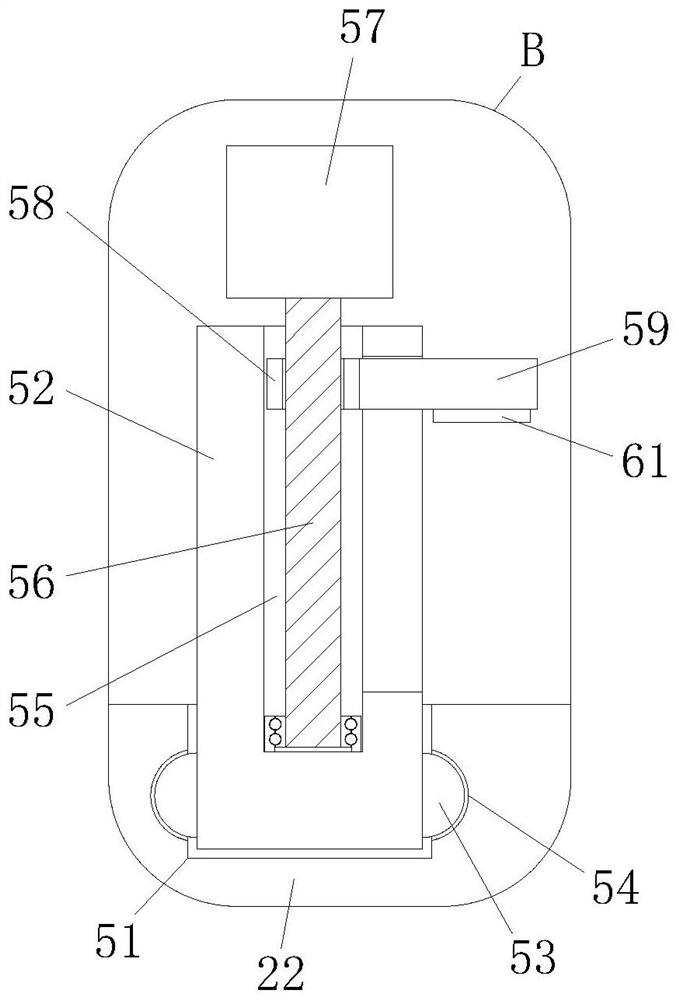

[0036] see Figure 1-9 As shown, a composite fiber non-woven fabric and a preparation method thereof include a non-woven fabric body 7; a composite fiber mechanism is provided on the outer side of the non-woven fabric body 7, and the composite fiber mechanism includes a vinylon moisture absorption layer 81, silver fibers The antibacterial layer 82 and the nylon wear-resistant layer 83, the vinylon moisture-absorbing layer 81 is fixedly connected to the top of the non-woven fabric main body 7, the silver fiber antibacterial layer 82 is fixedly connected to the end of the vinylon moisture-absorbing layer 81 away from the non-woven fabric main body 7, The nylon wear-resistant layer 83 is fixedly connected to the end of the silver fiber antibacterial layer 82 away from the vinylon moisture-absorbing layer 81;

[0037] During operation, the function of the vinylon moisture-absorbing layer 81 enhances the fiber strength of the non-woven fabric as a whole and also enhances the overal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com